Geok Soon Hong

A Cost-Sensitive Deep Belief Network for Imbalanced Classification

May 05, 2018

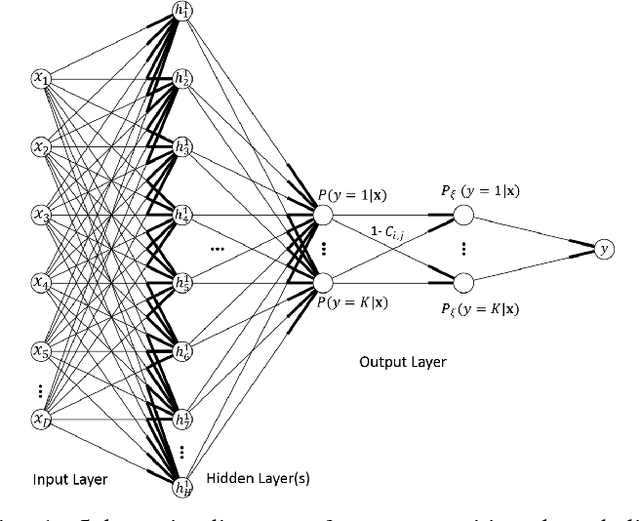

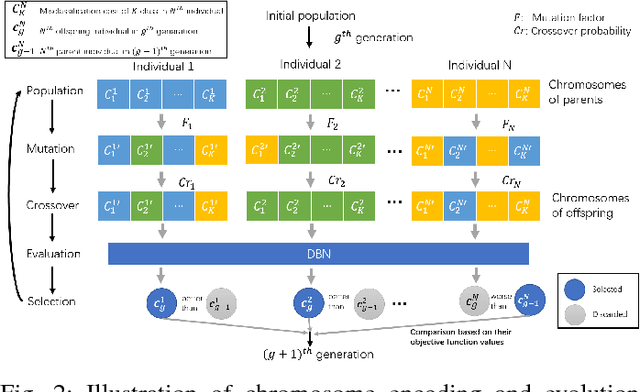

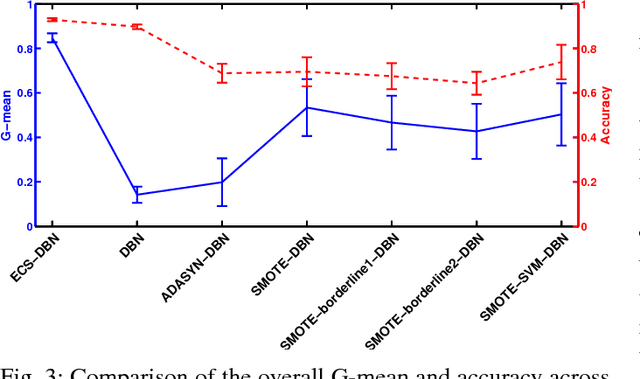

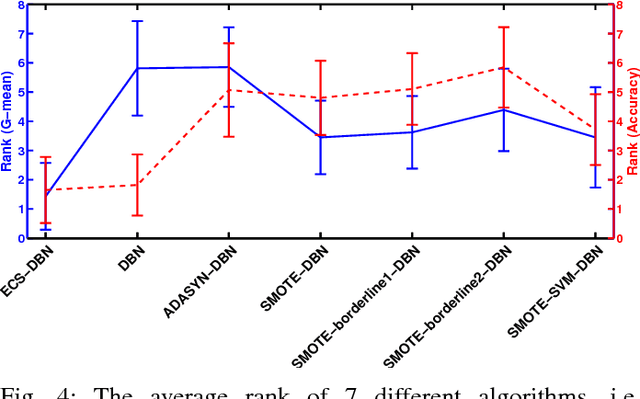

Abstract:Imbalanced data with a skewed class distribution are common in many real-world applications. Deep Belief Network (DBN) is a machine learning technique that is effective in classification tasks. However, conventional DBN does not work well for imbalanced data classification because it assumes equal costs for each class. To deal with this problem, cost-sensitive approaches assign different misclassification costs for different classes without disrupting the true data sample distributions. However, due to lack of prior knowledge, the misclassification costs are usually unknown and hard to choose in practice. Moreover, it has not been well studied as to how cost-sensitive learning could improve DBN performance on imbalanced data problems. This paper proposes an evolutionary cost-sensitive deep belief network (ECS-DBN) for imbalanced classification. ECS-DBN uses adaptive differential evolution to optimize the misclassification costs based on training data, that presents an effective approach to incorporating the evaluation measure (i.e. G-mean) into the objective function. We first optimize the misclassification costs, then apply them to deep belief network. Adaptive differential evolution optimization is implemented as the optimization algorithm that automatically updates its corresponding parameters without the need of prior domain knowledge. The experiments have shown that the proposed approach consistently outperforms the state-of-the-art on both benchmark datasets and real-world dataset for fault diagnosis in tool condition monitoring.

A Multi-State Diagnosis and Prognosis Framework with Feature Learning for Tool Condition Monitoring

Apr 30, 2018

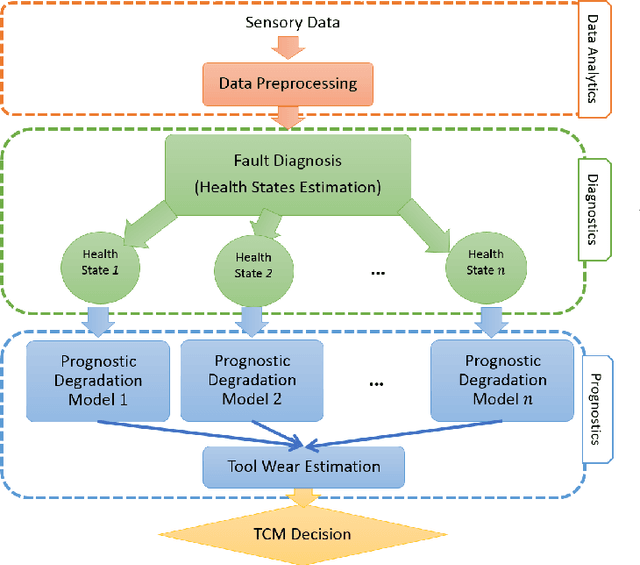

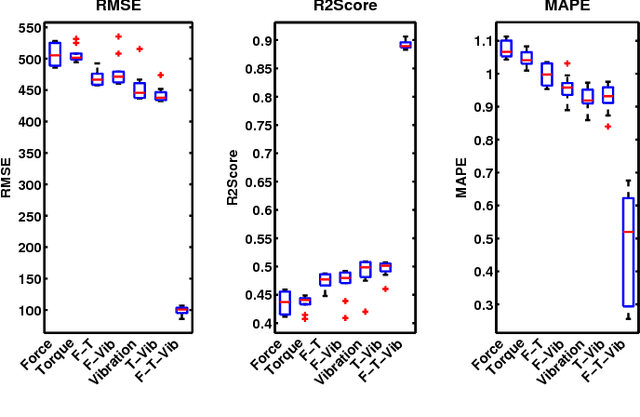

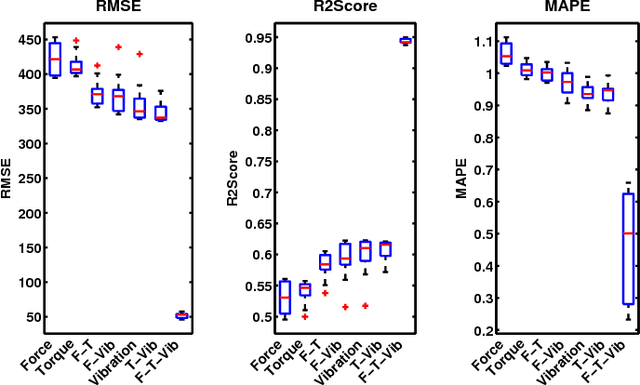

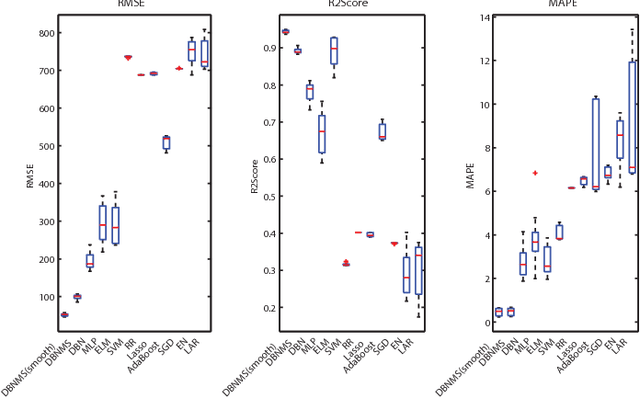

Abstract:In this paper, a multi-state diagnosis and prognosis (MDP) framework is proposed for tool condition monitoring via a deep belief network based multi-state approach (DBNMS). For fault diagnosis, a cost-sensitive deep belief network (namely ECS-DBN) is applied to deal with the imbalanced data problem for tool state estimation. An appropriate prognostic degradation model is then applied for tool wear estimation based on the different tool states. The proposed framework has the advantage of automatic feature representation learning and shows better performance in accuracy and robustness. The effectiveness of the proposed DBNMS is validated using a real-world dataset obtained from the gun drilling process. This dataset contains a large amount of measured signals involving different tool geometries under various operating conditions. The DBNMS is examined for both the tool state estimation and tool wear estimation tasks. In the experimental studies, the prediction results are evaluated and compared with popular machine learning approaches, which show the superior performance of the proposed DBNMS approach.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge