Jamie Paik

Flexible and Foldable: Workspace Analysis and Object Manipulation Using a Soft, Interconnected, Origami-Inspired Actuator Array

Sep 17, 2025Abstract:Object manipulation is a fundamental challenge in robotics, where systems must balance trade-offs among manipulation capabilities, system complexity, and throughput. Distributed manipulator systems (DMS) use the coordinated motion of actuator arrays to perform complex object manipulation tasks, seeing widespread exploration within the literature and in industry. However, existing DMS designs typically rely on high actuator densities and impose constraints on object-to-actuator scale ratios, limiting their adaptability. We present a novel DMS design utilizing an array of 3-DoF, origami-inspired robotic tiles interconnected by a compliant surface layer. Unlike conventional DMS, our approach enables manipulation not only at the actuator end effectors but also across a flexible surface connecting all actuators; creating a continuous, controllable manipulation surface. We analyse the combined workspace of such a system, derive simple motion primitives, and demonstrate its capabilities to translate simple geometric objects across an array of tiles. By leveraging the inter-tile connective material, our approach significantly reduces actuator density, increasing the area over which an object can be manipulated by x1.84 without an increase in the number of actuators. This design offers a lower cost and complexity alternative to traditional high-density arrays, and introduces new opportunities for manipulation strategies that leverage the flexibility of the interconnected surface.

Vibration of Soft, Twisted Beams for Under-Actuated Quadrupedal Locomotion

Jul 03, 2025Abstract:Under-actuated compliant robotic systems offer a promising approach to mitigating actuation and control challenges by harnessing pre-designed, embodied dynamic behaviors. This paper presents Flix-Walker, a novel, untethered, centimeter-scale quadrupedal robot inspired by compliant under-actuated mechanisms. Flix-Walker employs flexible, helix-shaped beams as legs, which are actuated by vibrations from just two motors to achieve three distinct mobility modes. We analyze the actuation parameters required to generate various locomotion modes through both simulation and prototype experiments. The effects of system and environmental variations on locomotion performance are examined, and we propose a generic metric for selecting control parameters that produce robust and functional motions. Experiments validate the effectiveness and robustness of these actuation parameters within a closed-loop control framework, demonstrating reliable trajectory-tracking and self-navigation capabilities.

CPG-Based Manipulation with Multi-Module Origami Robot Surface

Feb 26, 2025

Abstract:Robotic manipulators often face challenges in handling objects of different sizes and materials, limiting their effectiveness in practical applications. This issue is particularly pronounced when manipulating meter-scale objects or those with varying stiffness, as traditional gripping techniques and strategies frequently prove inadequate. In this letter, we introduce a novel surface-based multi-module robotic manipulation framework that utilizes a Central Pattern Generator (CPG)-based motion generator, combined with a simulation-based optimization method to determine the optimal manipulation parameters for a multi-module origami robotic surface (Ori-Pixel). This approach allows for the manipulation of objects ranging from centimeters to meters in size, with varying stiffness and shape. The optimized CPG parameters are tested through both dynamic simulations and a series of prototype experiments involving a wide range of objects differing in size, weight, shape, and material, demonstrating robust manipulation capabilities.

Surface-Based Manipulation

Feb 26, 2025

Abstract:Intelligence lies not only in the brain but in the body. The shape of our bodies can influence how we think and interact with the physical world. In robotics research, interacting with the physical world is crucial as it allows robots to manipulate objects in various real-life scenarios. Conventional robotic manipulation strategies mainly rely on finger-shaped end effectors. However, achieving stable grasps on fragile, deformable, irregularly shaped, or slippery objects is challenging due to difficulties in establishing stable force or geometric constraints. Here, we present surface-based manipulation strategies that diverge from classical grasping approaches, using with flat surfaces as minimalist end-effectors. By changing the position and orientation of these surfaces, objects can be translated, rotated and even flipped across the surface using closed-loop control strategies. Since this method does not rely on stable grasp, it can adapt to objects of various shapes, sizes, and stiffness levels, even enabling the manipulation the shape of deformable objects. Our results provide a new perspective for solving complex manipulation problems.

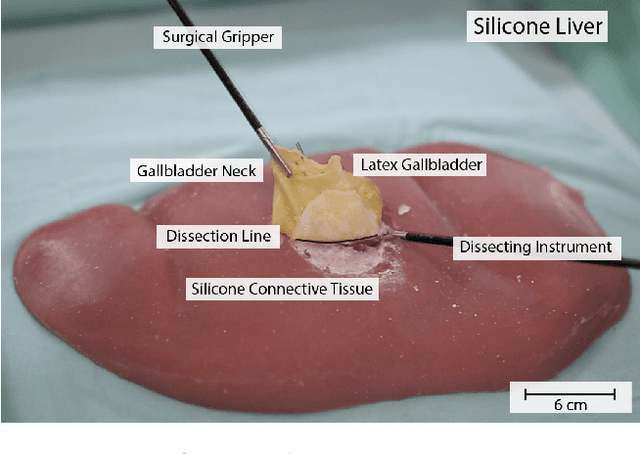

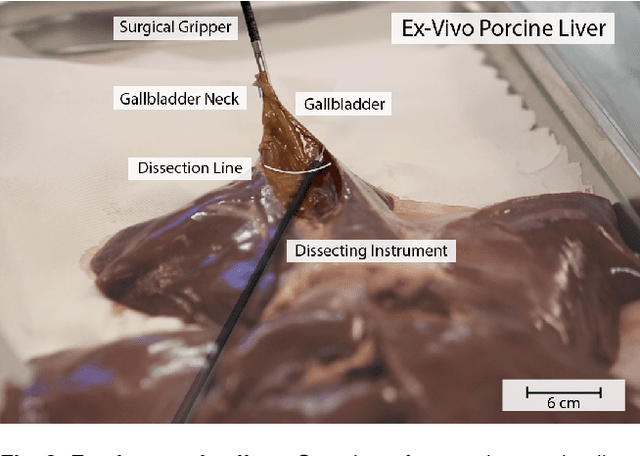

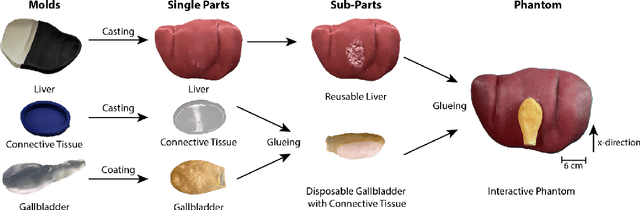

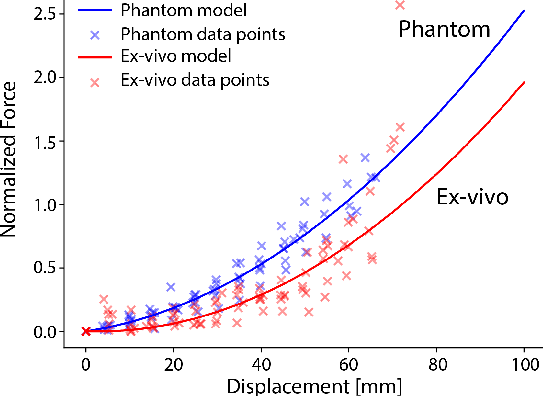

Interactive Surgical Liver Phantom for Cholecystectomy Training

Sep 05, 2024

Abstract:Training and prototype development in robot-assisted surgery requires appropriate and safe environments for the execution of surgical procedures. Current dry lab laparoscopy phantoms often lack the ability to mimic complex, interactive surgical tasks. This work presents an interactive surgical phantom for the cholecystectomy. The phantom enables the removal of the gallbladder during cholecystectomy by allowing manipulations and cutting interactions with the synthetic tissue. The force-displacement behavior of the gallbladder is modelled based on retraction demonstrations. The force model is compared to the force model of ex-vivo porcine gallbladders and evaluated on its ability to estimate retraction forces.

Compact pneumatic clutch with integrated stiffness variation and position feedback

Mar 05, 2021

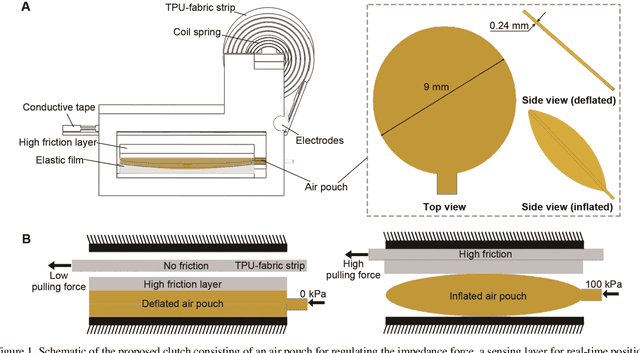

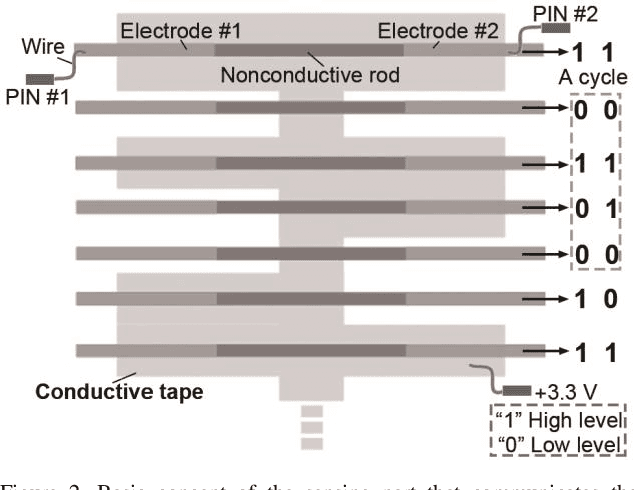

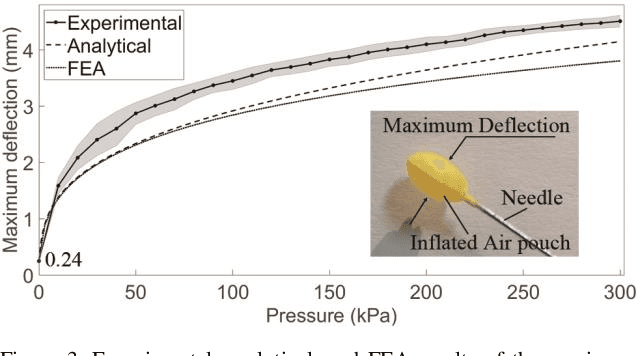

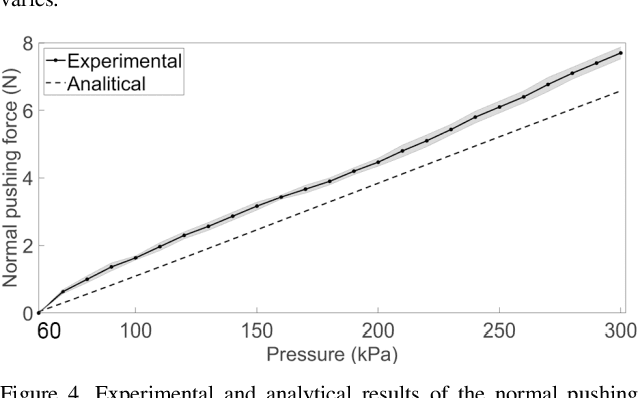

Abstract:Stiffness variation and real-time position feedback are critical for any robotic system but most importantly for active and wearable devices to interact with the user and environment. Currently, for compact sizes, there is a lack of solutions bringing high-fidelity feedback and maintaining design and functional integrity. In this work, we propose a novel minimal clutch with integrated stiffness variation and real-time position feedback whose performance surpasses conventional jamming solutions. We introduce integrated design, modeling, and verification of the clutch in detail. Preliminary experimental results show the change in impedance force of the clutch is close to 24-fold at the maximum force density of 15.64 N/cm2. We validated the clutch experimentally in (1) enhancing the bending stiffness of a soft actuator to increase a soft manipulator's gripping force by 73%; (2) enabling a soft cylindrical actuator to execute omnidirectional movement; (3) providing real-time position feedback for hand posture detection and impedance force for kinesthetic haptic feedback. This manuscript presents the functional components with a focus on the integrated design methodology, which will have an impact on the development of soft robots and wearable devices.

Soft Pneumatic Gelatin Actuator for Edible Robotics

Mar 04, 2017

Abstract:We present a fully edible pneumatic actuator based on gelatin-glycerol composite. The actuator is monolithic, fabricated via a molding process, and measures 90 mm in length, 20 mm in width, and 17 mm in thickness. Thanks to the composite mechanical characteristics similar to those of silicone elastomers, the actuator exhibits a bending angle of 170.3 {\deg} and a blocked force of 0.34 N at the applied pressure of 25 kPa. These values are comparable to elastomer based pneumatic actuators. As a validation example, two actuators are integrated to form a gripper capable of handling various objects, highlighting the high performance and applicability of the edible actuator. These edible actuators, combined with other recent edible materials and electronics, could lay the foundation for a new type of edible robots.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge