Daniel M. Aukes

Vibration of Soft, Twisted Beams for Under-Actuated Quadrupedal Locomotion

Jul 03, 2025Abstract:Under-actuated compliant robotic systems offer a promising approach to mitigating actuation and control challenges by harnessing pre-designed, embodied dynamic behaviors. This paper presents Flix-Walker, a novel, untethered, centimeter-scale quadrupedal robot inspired by compliant under-actuated mechanisms. Flix-Walker employs flexible, helix-shaped beams as legs, which are actuated by vibrations from just two motors to achieve three distinct mobility modes. We analyze the actuation parameters required to generate various locomotion modes through both simulation and prototype experiments. The effects of system and environmental variations on locomotion performance are examined, and we propose a generic metric for selecting control parameters that produce robust and functional motions. Experiments validate the effectiveness and robustness of these actuation parameters within a closed-loop control framework, demonstrating reliable trajectory-tracking and self-navigation capabilities.

Tunable Dynamic Walking via Soft Twisted Beam Vibration

Nov 01, 2022

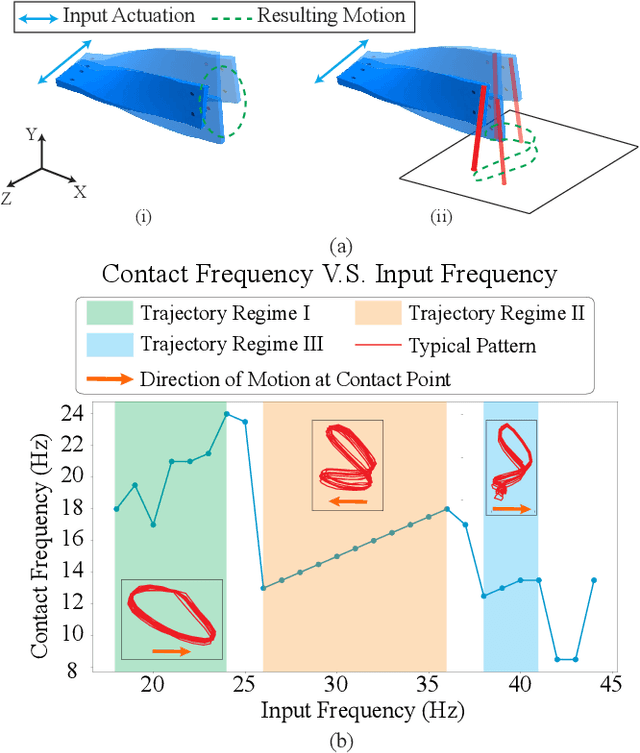

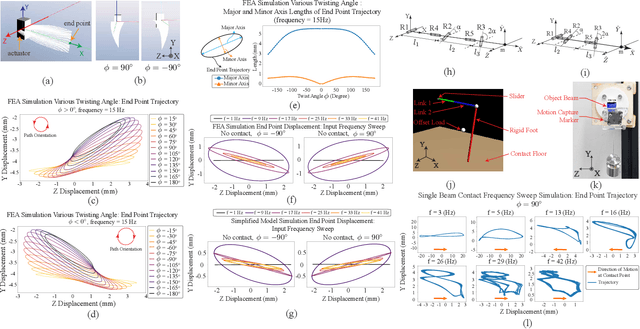

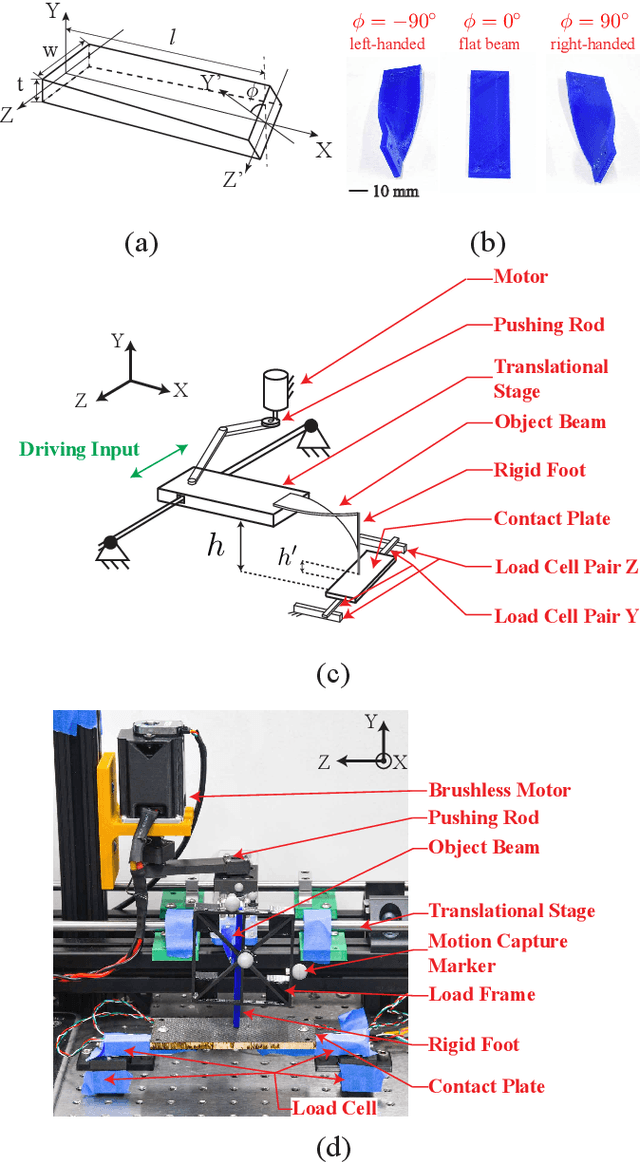

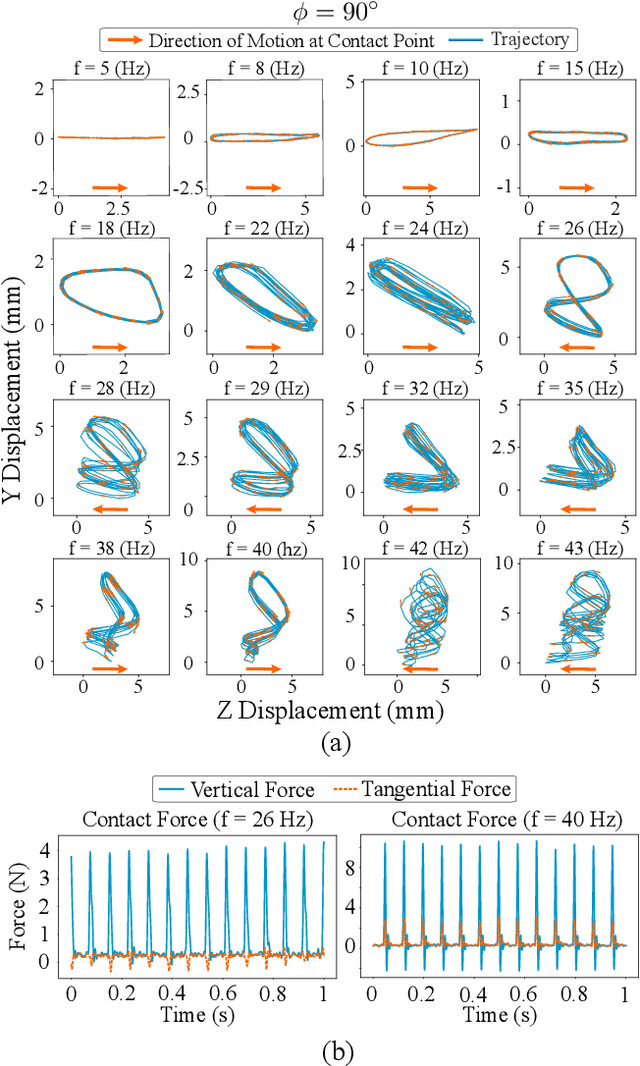

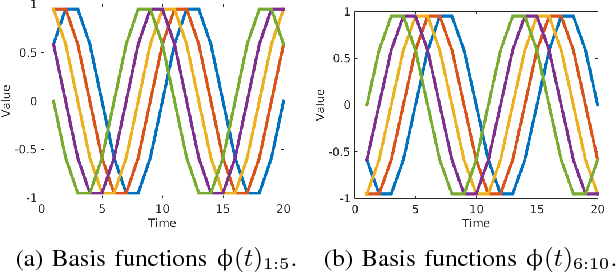

Abstract:We propose a novel mechanism that propagates vibration through soft twisted beams, taking advantage of dynamically-coupled anisotropic stiffness to simplify the actuation of walking robots. Using dynamic simulation and experimental approaches, we show that the coupled stiffness of twisted beams with terrain contact can be controlled to generate a variety of complex trajectories by changing the frequency of the input signal. This work reveals how ground contact influences the system's dynamic behavior, supporting the design of walking robots inspired by this phenomenon. We also show that the proposed twisted beam produces a tunable walking gait from a single vibrational input.

Compliant Fins for Locomotion in Granular Media

Jan 16, 2021

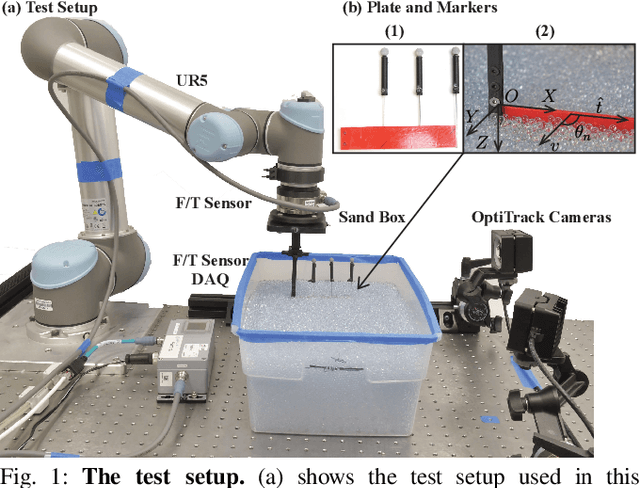

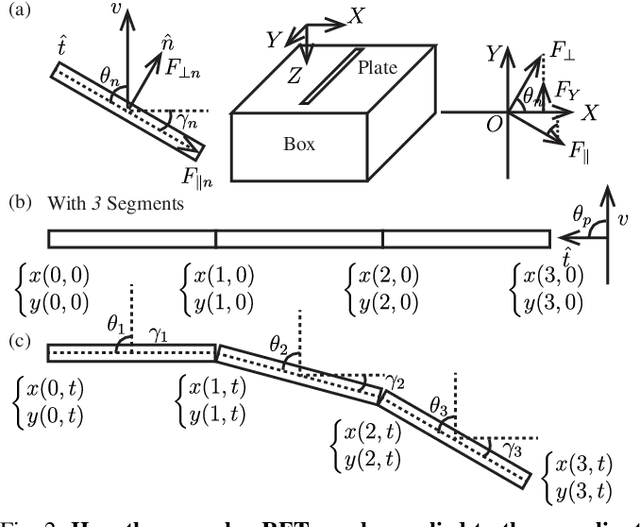

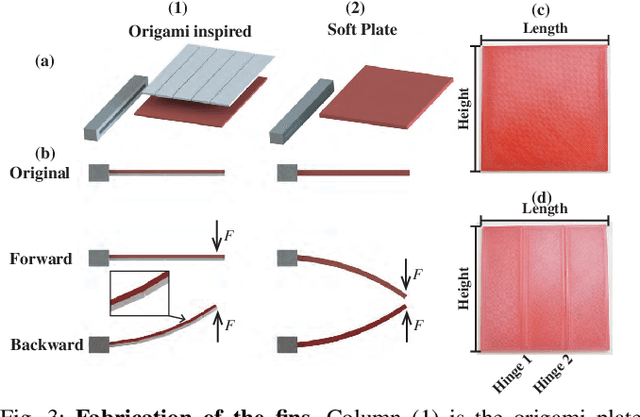

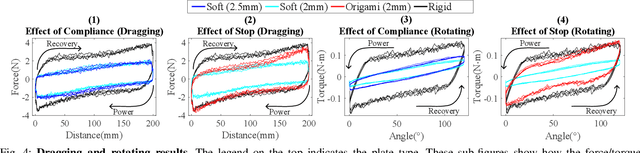

Abstract:In this paper, we present an approach to study the behavior of compliant plates in granular media and optimize the performance of a robot that utilizes this technique for mobility. From previous work and fundamental tests on thin plate force generation inside granular media, we introduce an origami-inspired mechanism with non-linear compliance in the joints that can be used in granular propulsion. This concept utilizes one-sided joint limits to create an asymmetric gait cycle that avoids more complicated alternatives often found in other swimming/digging robots. To analyze its locomotion as well as its shape and propulsive force, we utilize granular Resistive Force Theory (RFT) as a starting point. Adding compliance to this theory enables us to predict the time-based evolution of compliant plates when they are dragged and rotated. It also permits more rational design of swimming robots where fin design variables may be optimized against the characteristics of the granular medium. This is done using a Python-based dynamic simulation library to model the deformation of the plates and optimize aspects of the robot's gait. Finally, we prototype and test robot with a gait optimized using the modelling techniques mentioned above.

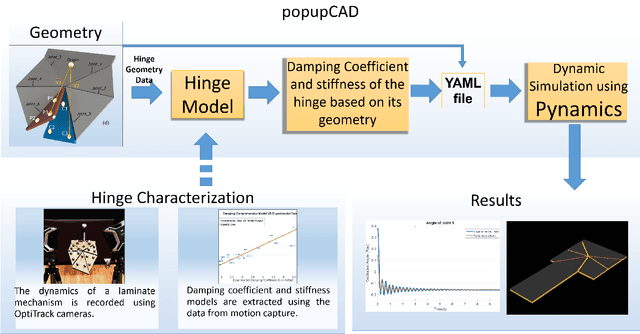

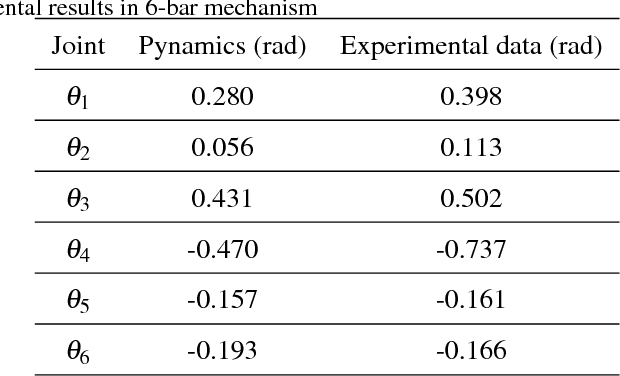

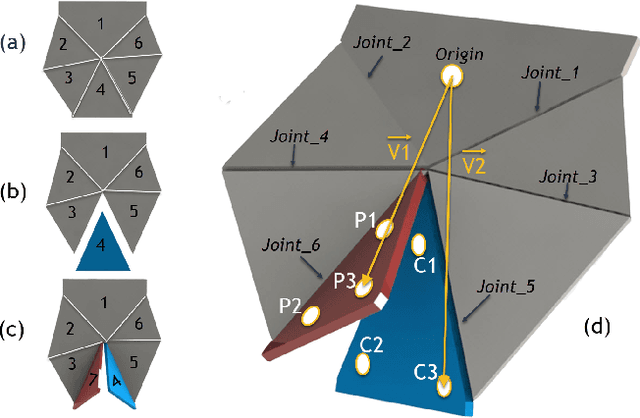

An Integrated Design and Simulation Environment for Rapid Prototyping of Laminate Robotic Mechanisms

Aug 10, 2018

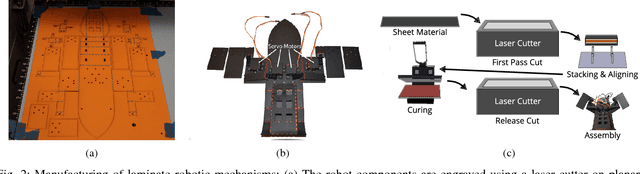

Abstract:Laminate mechanisms are a reliable concept in producing lowcost robots for educational and commercial purposes. These mechanisms are produced using low-cost manufacturing techniques which have improved significantly during recent years and are more accessible to novices and hobbyists. However, iterating through the design space to come up with the best design for a robot is still a time consuming and rather expensive task and therefore, there is still a need for model-based analysis before manufacturing. Until now, there has been no integrated design and analysis software for laminate robots. This paper addresses some of the issues surrounding laminate analysis by introducing a companion to an existing laminate design tool that automates the generation of dynamic equations and produces simulation results via rendered plots and videos. We have validated the accuracy of the software by comparing the position, velocity and acceleration of the simulated mechanisms with the measurements taken from physical laminate prototypes using a motion capture system.

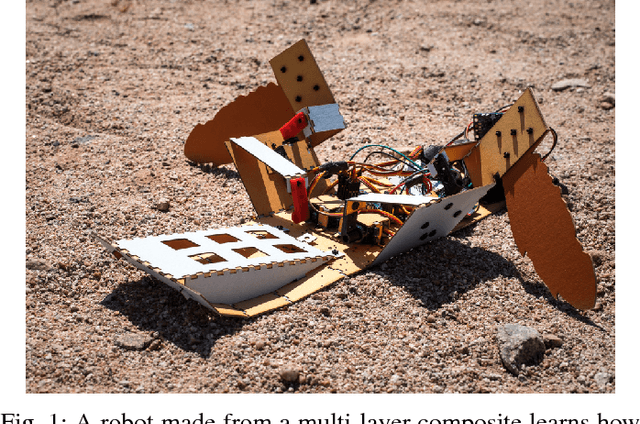

From the Lab to the Desert: Fast Prototyping and Learning of Robot Locomotion

Jun 06, 2017

Abstract:We present a methodology for fast prototyping of morphologies and controllers for robot locomotion. Going beyond simulation-based approaches, we argue that the form and function of a robot, as well as their interplay with real-world environmental conditions are critical. Hence, fast design and learning cycles are necessary to adapt robot shape and behavior to their environment. To this end, we present a combination of laminate robot manufacturing and sample-efficient reinforcement learning. We leverage this methodology to conduct an extensive robot learning experiment. Inspired by locomotion in sea turtles, we design a low-cost crawling robot with variable, interchangeable fins. Learning is performed using both bio-inspired and original fin designs in an artificial indoor environment as well as a natural environment in the Arizona desert. The findings of this study show that static policies developed in the laboratory do not translate to effective locomotion strategies in natural environments. In contrast to that, sample-efficient reinforcement learning can help to rapidly accommodate changes in the environment or the robot.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge