Fabio Bergonti

Istituto Italiano di Tecnologia, University of Manchester

CAD-Driven Co-Design for Flight-Ready Jet-Powered Humanoids

Sep 18, 2025Abstract:This paper presents a CAD-driven co-design framework for optimizing jet-powered aerial humanoid robots to execute dynamically constrained trajectories. Starting from the iRonCub-Mk3 model, a Design of Experiments (DoE) approach is used to generate 5,000 geometrically varied and mechanically feasible designs by modifying limb dimensions, jet interface geometry (e.g., angle and offset), and overall mass distribution. Each model is constructed through CAD assemblies to ensure structural validity and compatibility with simulation tools. To reduce computational cost and enable parameter sensitivity analysis, the models are clustered using K-means, with representative centroids selected for evaluation. A minimum-jerk trajectory is used to assess flight performance, providing position and velocity references for a momentum-based linearized Model Predictive Control (MPC) strategy. A multi-objective optimization is then conducted using the NSGA-II algorithm, jointly exploring the space of design centroids and MPC gain parameters. The objectives are to minimize trajectory tracking error and mechanical energy expenditure. The framework outputs a set of flight-ready humanoid configurations with validated control parameters, offering a structured method for selecting and implementing feasible aerial humanoid designs.

Physics-Informed Learning for the Friction Modeling of High-Ratio Harmonic Drives

Oct 16, 2024

Abstract:This paper presents a scalable method for friction identification in robots equipped with electric motors and high-ratio harmonic drives, utilizing Physics-Informed Neural Networks (PINN). This approach eliminates the need for dedicated setups and joint torque sensors by leveraging the robo\v{t}s intrinsic model and state data. We present a comprehensive pipeline that includes data acquisition, preprocessing, ground truth generation, and model identification. The effectiveness of the PINN-based friction identification is validated through extensive testing on two different joints of the humanoid robot ergoCub, comparing its performance against traditional static friction models like the Coulomb-viscous and Stribeck-Coulomb-viscous models. Integrating the identified PINN-based friction models into a two-layer torque control architecture enhances real-time friction compensation. The results demonstrate significant improvements in control performance and reductions in energy losses, highlighting the scalability and robustness of the proposed method, also for application across a large number of joints as in the case of humanoid robots.

From CAD to URDF: Co-Design of a Jet-Powered Humanoid Robot Including CAD Geometry

Oct 11, 2024

Abstract:Co-design optimization strategies usually rely on simplified robot models extracted from CAD. While these models are useful for optimizing geometrical and inertial parameters for robot control, they might overlook important details essential for prototyping the optimized mechanical design. For instance, they may not account for mechanical stresses exerted on the optimized geometries and the complexity of assembly-level design. In this paper, we introduce a co-design framework aimed at improving both the control performance and mechanical design of our robot. Specifically, we identify the robot links that significantly influence control performance. The geometric characteristics of these links are parameterized and optimized using a multi-objective evolutionary algorithm to achieve optimal control performance. Additionally, an automated Finite Element Method (FEM) analysis is integrated into the framework to filter solutions not satisfying the required structural safety margin. We validate the framework by applying it to enhance the mechanical design for flight performance of the jet-powered humanoid robot iRonCub.

Fron CAD to URDF: Co-Design of a Jet-Powered Humanoid Robot Including CAD Geometry

Oct 10, 2024

Abstract:Co-design optimization strategies usually rely on simplified robot models extracted from CAD. While these models are useful for optimizing geometrical and inertial parameters for robot control, they might overlook important details essential for prototyping the optimized mechanical design. For instance, they may not account for mechanical stresses exerted on the optimized geometries and the complexity of assembly-level design. In this paper, we introduce a co-design framework aimed at improving both the control performance and mechanical design of our robot. Specifically, we identify the robot links that significantly influence control performance. The geometric characteristics of these links are parameterized and optimized using a multi-objective evolutionary algorithm to achieve optimal control performance. Additionally, an automated Finite Element Method (FEM) analysis is integrated into the framework to filter solutions not satisfying the required structural safety margin. We validate the framework by applying it to enhance the mechanical design for flight performance of the jet-powered humanoid robot iRonCub.

Codesign of Humanoid Robots for Ergonomy Collaboration with Multiple Humans via Genetic Algorithms and Nonlinear Optimization

Dec 12, 2023

Abstract:Ergonomics is a key factor to consider when designing control architectures for effective physical collaborations between humans and humanoid robots. In contrast, ergonomic indexes are often overlooked in the robot design phase, which leads to suboptimal performance in physical human-robot interaction tasks. This paper proposes a novel methodology for optimizing the design of humanoid robots with respect to ergonomic indicators associated with the interaction of multiple agents. Our approach leverages a dynamic and kinematic parameterization of the robot link and motor specifications to seek for optimal robot designs using a bilevel optimization approach. Specifically, a genetic algorithm first generates robot designs by selecting the link and motor characteristics. Then, we use nonlinear optimization to evaluate interaction ergonomy indexes during collaborative payload lifting with different humans and weights. To assess the effectiveness of our approach, we compare the optimal design obtained using bilevel optimization against the design obtained using nonlinear optimization. Our results show that the proposed approach significantly improves ergonomics in terms of energy expenditure calculated in two reference scenarios involving static and dynamic robot motions. We plan to apply our methodology to drive the design of the ergoCub2 robot, a humanoid intended for optimal physical collaboration with humans in diverse environments

Co-Design Optimisation of Morphing Topology and Control of Winged Drones

Sep 25, 2023Abstract:The design and control of winged aircraft and drones is an iterative process aimed at identifying a compromise of mission-specific costs and constraints. When agility is required, shape-shifting (morphing) drones represent an efficient solution. However, morphing drones require the addition of actuated joints that increase the topology and control coupling, making the design process more complex. We propose a co-design optimisation method that assists the engineers by proposing a morphing drone's conceptual design that includes topology, actuation, morphing strategy, and controller parameters. The method consists of applying multi-objective constraint-based optimisation to a multi-body winged drone with trajectory optimisation to solve the motion intelligence problem under diverse flight mission requirements. We show that co-designed morphing drones outperform fixed-winged drones in terms of energy efficiency and agility, suggesting that the proposed co-design method could be a useful addition to the aircraft engineering toolbox.

Whole-Body Trajectory Optimization for Robot Multimodal Locomotion

Nov 23, 2022

Abstract:The general problem of planning feasible trajectories for multimodal robots is still an open challenge. This paper presents a whole-body trajectory optimisation approach that addresses this challenge by combining methods and tools developed for aerial and legged robots. First, robot models that enable the presented whole-body trajectory optimisation framework are presented. The key model is the so-called robot centroidal momentum, the dynamics of which is directly related to the models of the robot actuation for aerial and terrestrial locomotion. Then, the paper presents how these models can be employed in an optimal control problem to generate either terrestrial or aerial locomotion trajectories with a unified approach. The optimisation problem considers robot kinematics, momentum, thrust forces and their bounds. The overall approach is validated using the multimodal robot iRonCub, a flying humanoid robot that expresses a degree of terrestrial and aerial locomotion. To solve the associated optimal trajectory generation problem, we employ ADAM, a custom-made open-source library that implements a collection of algorithms for calculating rigid-body dynamics using CasADi.

Torque and velocity controllers to perform jumps with a humanoid robot: theory and implementation on the iCub robot

Jul 05, 2022

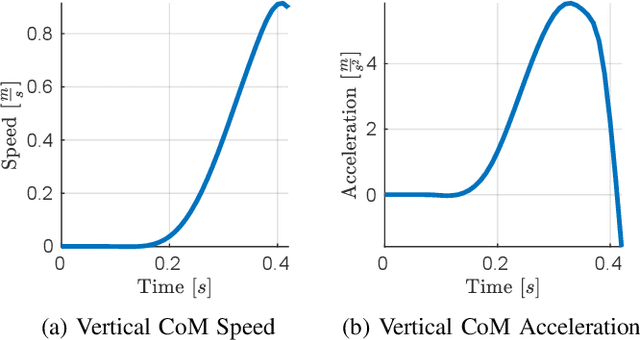

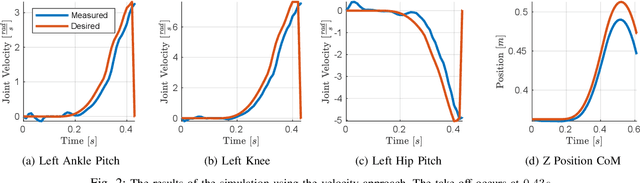

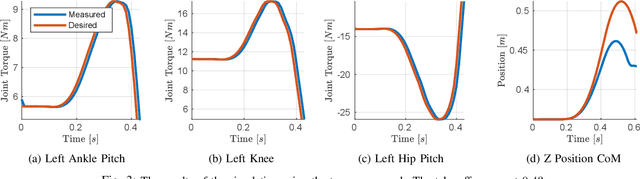

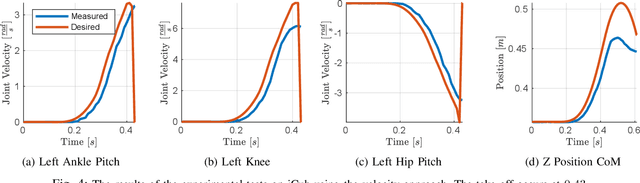

Abstract:Jumping can be an effective way of locomotion to overcome small terrain gaps or obstacles. In this paper we propose two different approaches to perform jumps with a humanoid robot. Specifically, starting from a pre-defined CoM trajectory we develop the theory for a velocity controller and for a torque controller based on an optimization technique for the evaluation of the joints input. The controllers have been tested both in simulation and on the humanoid robot iCub. In simulation the robot was able to jump using both controllers, while the real system jumped with the velocity controller only. The results highlight the importance of controlling the centroidal angular momentum and they suggest that the joint performances, namely maximum power, of the legs and torso joints, and the low level control performances are fundamental to achieve acceptable results.

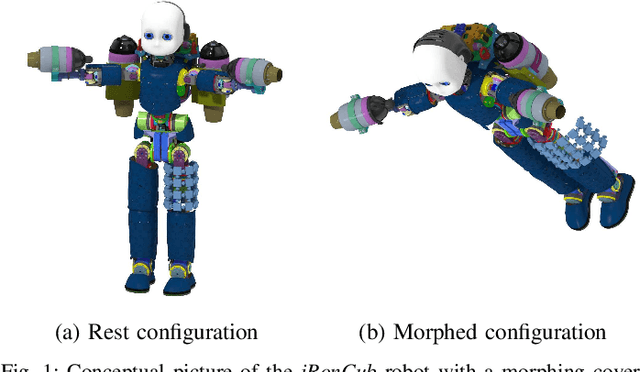

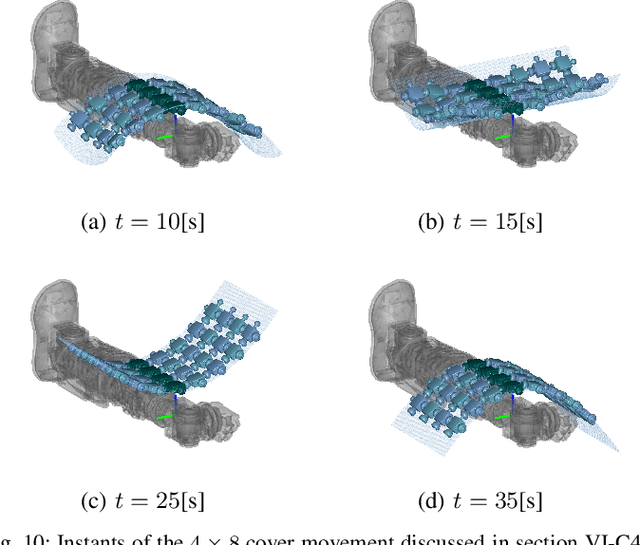

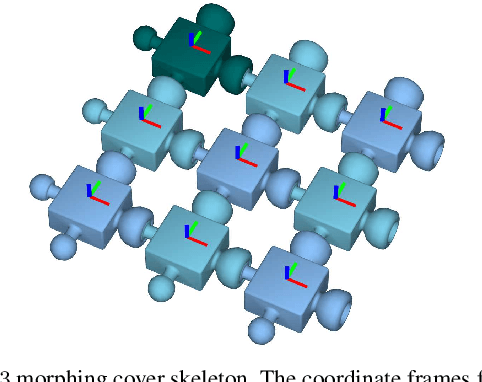

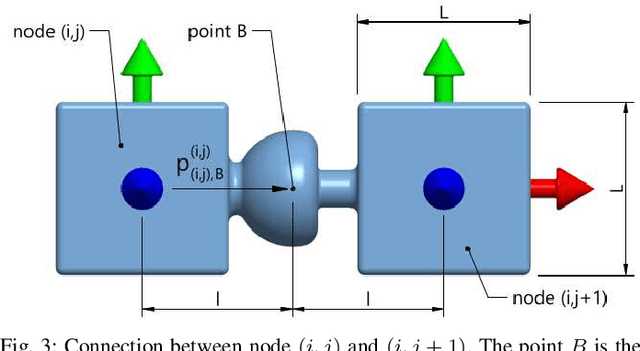

Modeling and Control of Morphing Covers for the Adaptive Morphology of Humanoid Robots

Jul 05, 2022

Abstract:This article takes a step to provide humanoid robots with adaptive morphology abilities. We present a systematic approach for enabling robotic covers to morph their shape, with an overall size fitting the anthropometric dimensions of a humanoid robot. More precisely, we present a cover concept consisting of two main components: a skeleton, which is a repetition of a basic element called node, and a soft membrane, which encloses the cover and deforms with its motion. This article focuses on the cover skeleton and addresses the challenging problems of node design, system modeling, motor positioning, and control design of the morphing system. The cover modeling focuses on kinematics, and a systematic approach for defining the system kinematic constraints is presented. Then, we apply genetic algorithms to find the motor locations so that the morphing cover is fully actuated. Finally, we present control algorithms that allow the cover to morph into a time-varying shape. The entire approach is validated by performing kinematic simulations with four different covers of square dimensions and having 3x3, 4x8, 8x8, and 20x20 nodes, respectively. For each cover, we apply the genetic algorithms to choose the motor locations and perform simulations for tracking a desired shape. The simulation results show that the presented approach ensures the covers to track a desired shape with good tracking performances.

Nonlinear Model Identification and Observer Design for Thrust Estimation of Small-scale Turbojet Engines

May 17, 2022

Abstract:Jet-powered vertical takeoff and landing (VTOL) drones require precise thrust estimation to ensure adequate stability margins and robust maneuvering. Small-scale turbojets have become good candidates for powering heavy aerial drones. However, due to limited instrumentation available in these turbojets, estimating the precise thrust using classical techniques is not straightforward. In this paper, we present a methodology to accurately estimate the online thrust for the small-scale turbojets used on the iRonCub - an aerial humanoid robot. We use a grey-box method to capture the turbojet system dynamics with a nonlinear state-space model based on the data acquired from a custom engine test bench. This model is then used to design an extended Kalman filter that estimates the turbojet thrust only from the angular speed measurements. We exploited the parameter estimation algorithm to ensure that the EKF gives smooth and accurate estimates even at engine failures. The designed EKF was validated on the test bench where the mean absolute error in estimated thrust was found to be within 2% of rated peak thrust.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge