Antonello Paolino

Istituto Italiano di Tecnologia, Università degli Studi di Napoli Federico II

From CAD to URDF: Co-Design of a Jet-Powered Humanoid Robot Including CAD Geometry

Oct 11, 2024

Abstract:Co-design optimization strategies usually rely on simplified robot models extracted from CAD. While these models are useful for optimizing geometrical and inertial parameters for robot control, they might overlook important details essential for prototyping the optimized mechanical design. For instance, they may not account for mechanical stresses exerted on the optimized geometries and the complexity of assembly-level design. In this paper, we introduce a co-design framework aimed at improving both the control performance and mechanical design of our robot. Specifically, we identify the robot links that significantly influence control performance. The geometric characteristics of these links are parameterized and optimized using a multi-objective evolutionary algorithm to achieve optimal control performance. Additionally, an automated Finite Element Method (FEM) analysis is integrated into the framework to filter solutions not satisfying the required structural safety margin. We validate the framework by applying it to enhance the mechanical design for flight performance of the jet-powered humanoid robot iRonCub.

Fron CAD to URDF: Co-Design of a Jet-Powered Humanoid Robot Including CAD Geometry

Oct 10, 2024

Abstract:Co-design optimization strategies usually rely on simplified robot models extracted from CAD. While these models are useful for optimizing geometrical and inertial parameters for robot control, they might overlook important details essential for prototyping the optimized mechanical design. For instance, they may not account for mechanical stresses exerted on the optimized geometries and the complexity of assembly-level design. In this paper, we introduce a co-design framework aimed at improving both the control performance and mechanical design of our robot. Specifically, we identify the robot links that significantly influence control performance. The geometric characteristics of these links are parameterized and optimized using a multi-objective evolutionary algorithm to achieve optimal control performance. Additionally, an automated Finite Element Method (FEM) analysis is integrated into the framework to filter solutions not satisfying the required structural safety margin. We validate the framework by applying it to enhance the mechanical design for flight performance of the jet-powered humanoid robot iRonCub.

Co-Design Optimisation of Morphing Topology and Control of Winged Drones

Sep 25, 2023Abstract:The design and control of winged aircraft and drones is an iterative process aimed at identifying a compromise of mission-specific costs and constraints. When agility is required, shape-shifting (morphing) drones represent an efficient solution. However, morphing drones require the addition of actuated joints that increase the topology and control coupling, making the design process more complex. We propose a co-design optimisation method that assists the engineers by proposing a morphing drone's conceptual design that includes topology, actuation, morphing strategy, and controller parameters. The method consists of applying multi-objective constraint-based optimisation to a multi-body winged drone with trajectory optimisation to solve the motion intelligence problem under diverse flight mission requirements. We show that co-designed morphing drones outperform fixed-winged drones in terms of energy efficiency and agility, suggesting that the proposed co-design method could be a useful addition to the aircraft engineering toolbox.

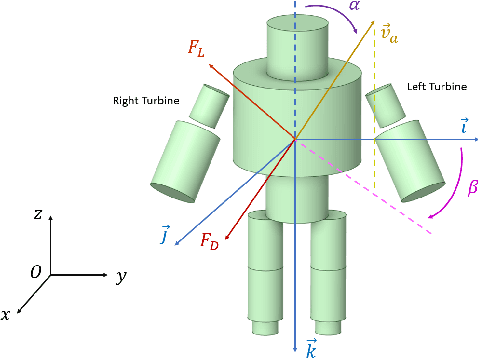

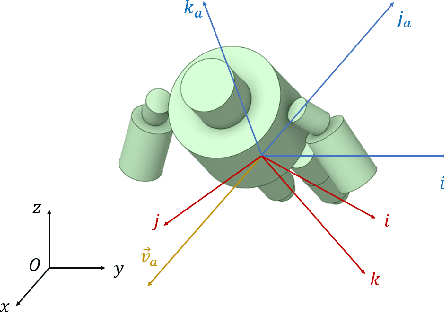

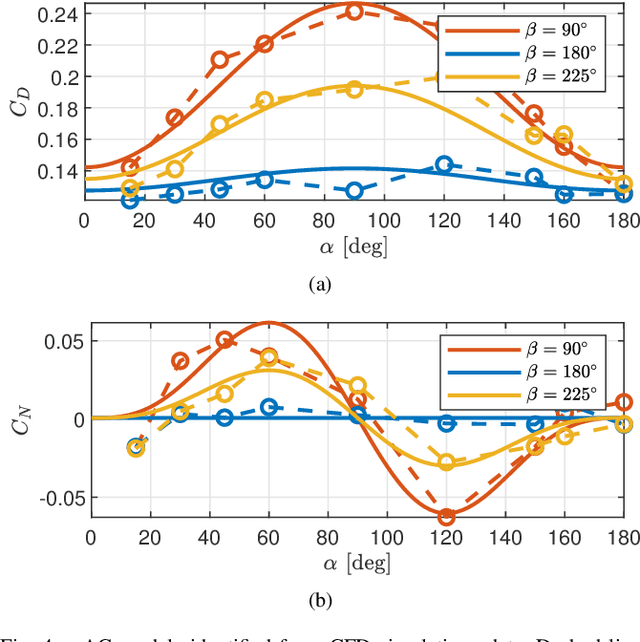

Centroidal Aerodynamic Modeling and Control of Flying Multibody Robots

May 17, 2022

Abstract:This paper presents a modeling and control framework for multibody flying robots subject to non-negligible aerodynamic forces acting on the centroidal dynamics. First, aerodynamic forces are calculated during robot flight in different operating conditions by means of Computational Fluid Dynamics (CFD) analysis. Then, analytical models of the aerodynamics coefficients are generated from the dataset collected with CFD analysis. The obtained simplified aerodynamic model is also used to improve the flying robot control design. We present two control strategies: compensating for the aerodynamic effects via feedback linearization and enforcing the controller robustness with gain-scheduling. Simulation results on the jet-powered humanoid robot iRonCub validate the proposed approach.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge