Audrey Sedal

Acoustic tactile sensing for mobile robot wheels

Feb 28, 2024

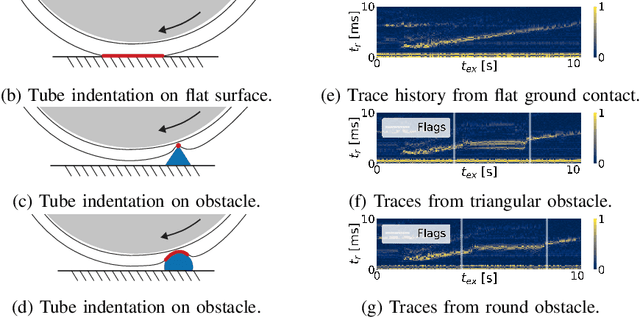

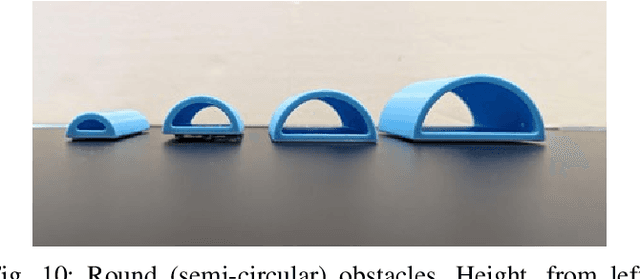

Abstract:Tactile sensing in mobile robots remains under-explored, mainly due to challenges related to sensor integration and the complexities of distributed sensing. In this work, we present a tactile sensing architecture for mobile robots based on wheel-mounted acoustic waveguides. Our sensor architecture enables tactile sensing along the entire circumference of a wheel with a single active component: an off-the-shelf acoustic rangefinder. We present findings showing that our sensor, mounted on the wheel of a mobile robot, is capable of discriminating between different terrains, detecting and classifying obstacles with different geometries, and performing collision detection via contact localization. We also present a comparison between our sensor and sensors traditionally used in mobile robots, and point to the potential for sensor fusion approaches that leverage the unique capabilities of our tactile sensing architecture. Our findings demonstrate that autonomous mobile robots can further leverage our sensor architecture for diverse mapping tasks requiring knowledge of terrain material, surface topology, and underlying structure.

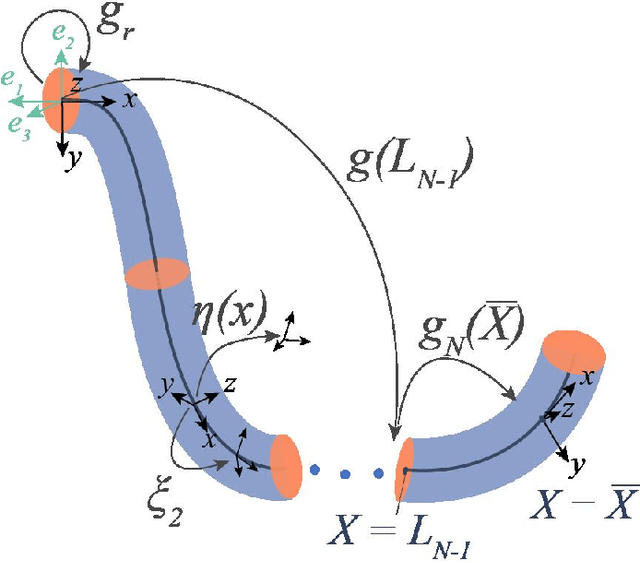

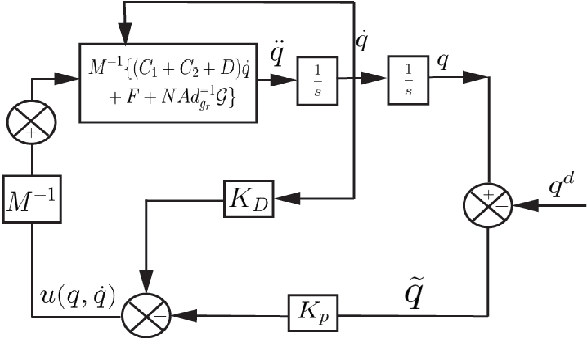

Lagrangian Properties and Control of Soft Robots Modeled with Discrete Cosserat Rods

Dec 10, 2023

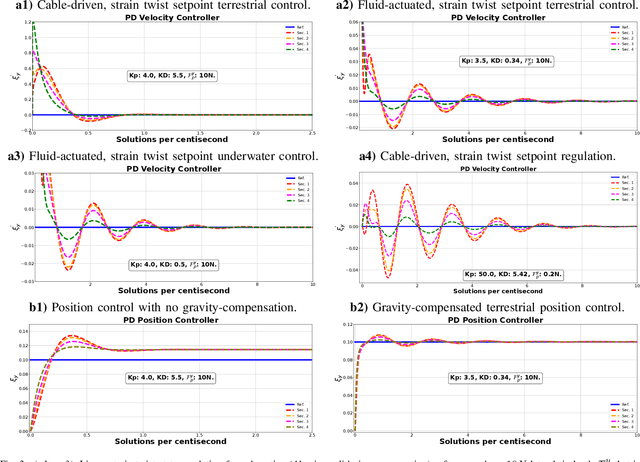

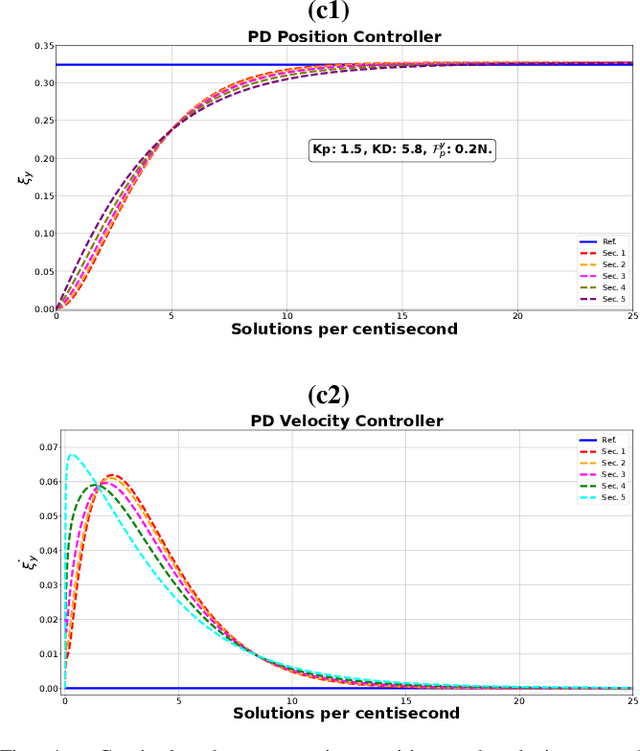

Abstract:The characteristic ``in-plane" bending associated with soft robots' deformation make them preferred over rigid robots in sophisticated manipulation and movement tasks. Executing such motion strategies to precision in soft deformable robots and structures is however fraught with modeling and control challenges given their infinite degrees-of-freedom. Imposing \textit{piecewise constant strains} (PCS) across (discretized) Cosserat microsolids on the continuum material however, their dynamics become amenable to tractable mathematical analysis. While this PCS model handles the characteristic difficult-to-model ``in-plane" bending well, its Lagrangian properties are not exploited for control in literature neither is there a rigorous study on the dynamic performance of multisection deformable materials for ``in-plane" bending that guarantees steady-state convergence. In this sentiment, we first establish the PCS model's structural Lagrangian properties. Second, we exploit these for control on various strain goal states. Third, we benchmark our hypotheses against an Octopus-inspired robot arm under different constant tip loads. These induce non-constant ``in-plane" deformation and we regulate strain states throughout the continuum in these configurations. Our numerical results establish convergence to desired equilibrium throughout the continuum in all of our tests. Within the bounds here set, we conjecture that our methods can find wide adoption in the control of cable- and fluid-driven multisection soft robotic arms; and may be extensible to the (learning-based) control of deformable agents employed in simulated, mixed, or augmented reality.

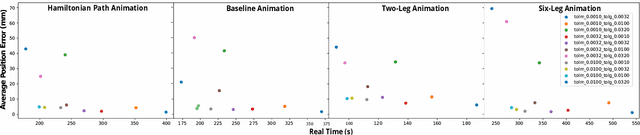

Soft Robots Learn to Crawl: Jointly Optimizing Design and Control with Sim-to-Real Transfer

Feb 09, 2022

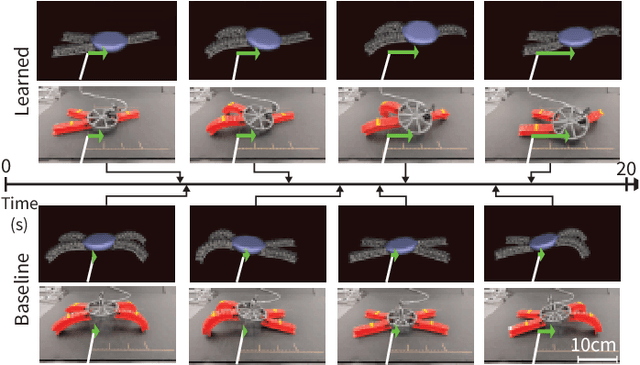

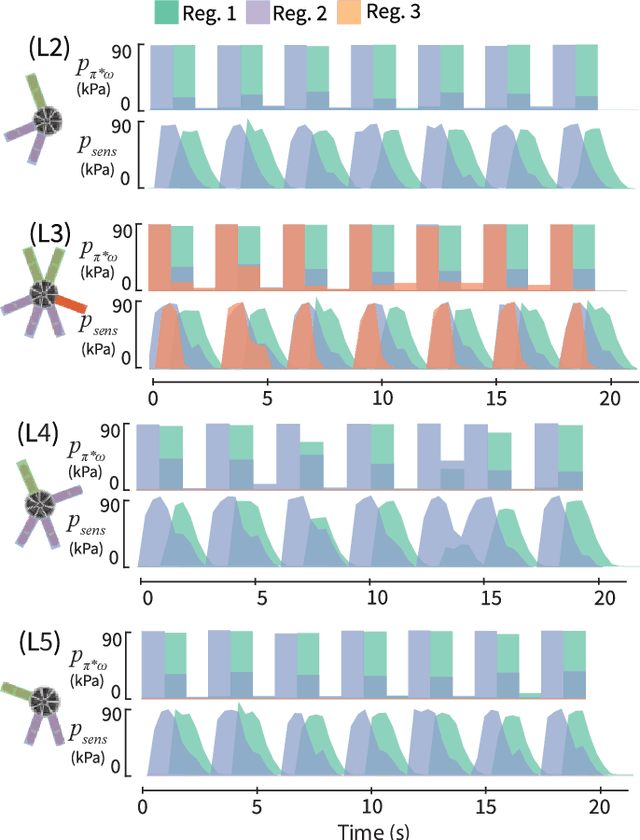

Abstract:This work provides a complete framework for the simulation, co-optimization, and sim-to-real transfer of the design and control of soft legged robots. The compliance of soft robots provides a form of "mechanical intelligence" -- the ability to passively exhibit behaviors that would otherwise be difficult to program. Exploiting this capacity requires careful consideration of the coupling between mechanical design and control. Co-optimization provides a promising means to generate sophisticated soft robots by reasoning over this coupling. However, the complex nature of soft robot dynamics makes it difficult to provide a simulation environment that is both sufficiently accurate to allow for sim-to-real transfer, while also being fast enough for contemporary co-optimization algorithms. In this work, we show that finite element simulation combined with recent model order reduction techniques provide both the efficiency and the accuracy required to successfully learn effective soft robot design-control pairs that transfer to reality. We propose a reinforcement learning-based framework for co-optimization and demonstrate successful optimization, construction, and zero-shot sim-to-real transfer of several soft crawling robots. Our learned robot outperforms an expert-designed crawling robot, showing that our approach can generate novel, high-performing designs even in well-understood domains.

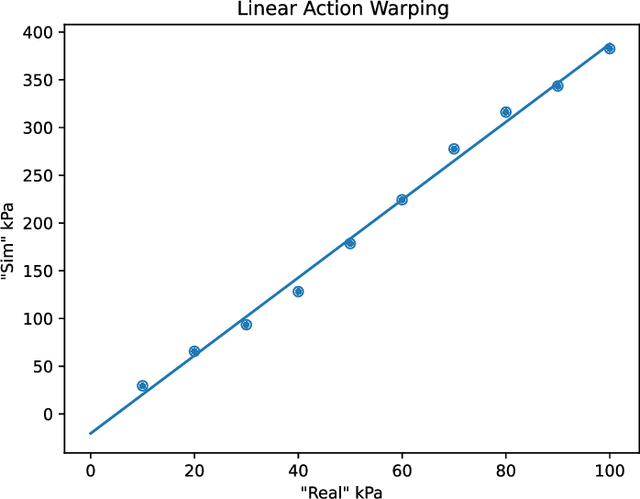

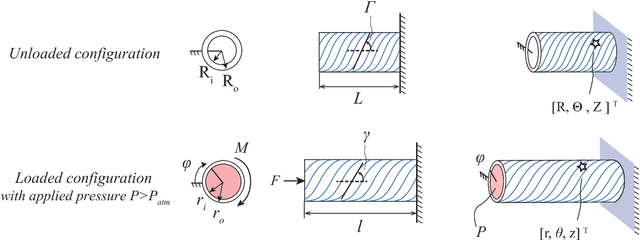

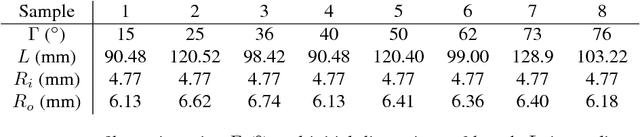

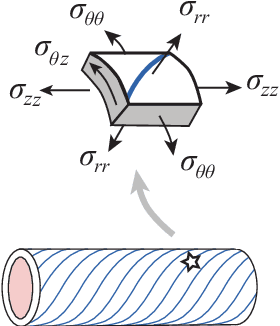

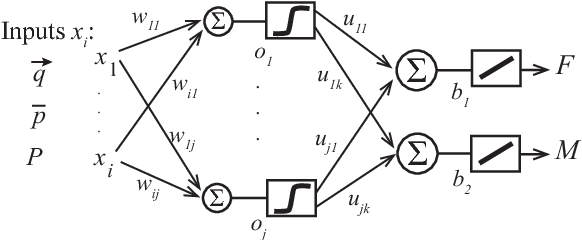

Comparison and Experimental Validation of Predictive Models for Soft, Fiber-Reinforced Actuators

Jan 31, 2019

Abstract:Successful soft robot modeling approaches appearing in recent literature have been based on a variety of distinct theories, including traditional robotic theory, continuum mechanics, and machine learning. Though specific modeling techniques have been developed for and validated against already realized systems, their strengths and weaknesses have not been explicitly compared against each other. In this paper, we show how three distinct model structures ---a lumped-parameter model, a continuum mechanical model, and a neural network--- compare in capturing the gross trends and specific features of the force generation of soft robotic actuators. In particular, we study models for Fiber Reinforced Elastomeric Enclosures (FREEs), which are a popular choice of soft actuator and that are used in several soft articulated systems, including soft manipulators, exoskeletons, grippers, and locomoting soft robots. We generated benchmark data by testing eight FREE samples that spanned broad design and kinematic spaces and compared the models on their ability to predict the loading-deformation relationships of these samples. This comparison shows the predictive capabilities of each model on individual actuators and each model's generalizability across the design space. While the neural net achieved the highest peak performance, the first principles-based models generalized best across all actuator design parameters tested. The results highlight the essential roles of mathematical structure and experimental parameter determination in building high-performing, generalizable soft actuator models with varying effort invested in system identification.

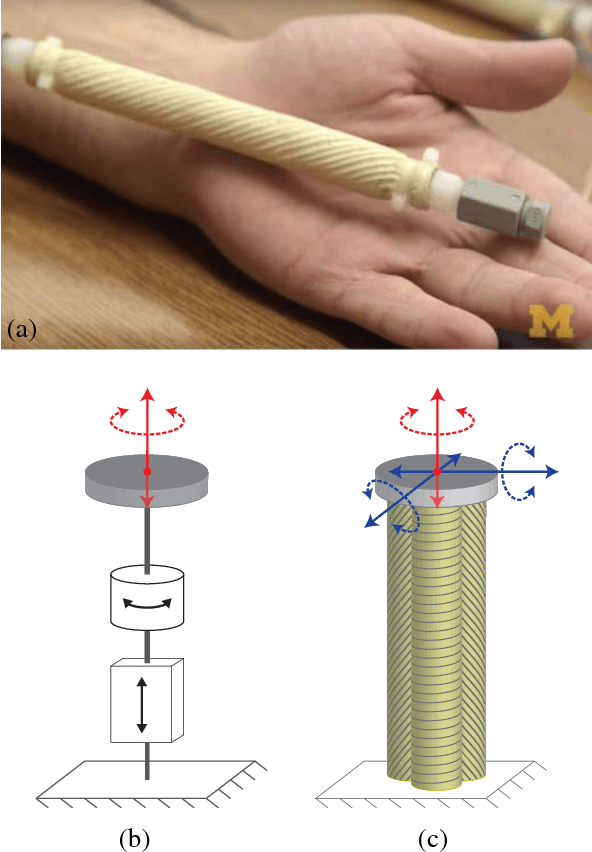

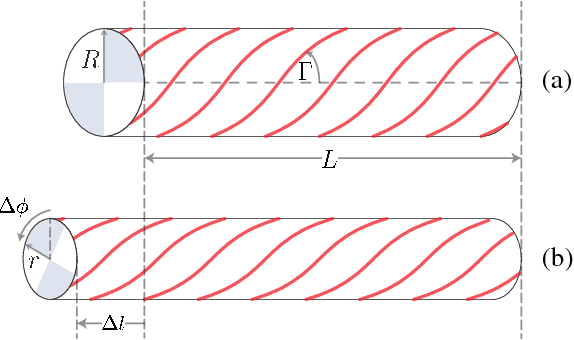

Force Generation by Parallel Combinations of Fiber-Reinforced Fluid-Driven Actuators

Oct 26, 2018

Abstract:The compliant structure of soft robotic systems enables a variety of novel capabilities in comparison to traditional rigid-bodied robots. A subclass of soft fluid-driven actuators known as fiber reinforced elastomeric enclosures (FREEs) is particularly well suited as actuators for these types of systems. FREEs are inherently soft and can impart spatial forces without imposing a rigid structure. Furthermore, they can be configured to produce a large variety of force and moment combinations. In this paper we explore the potential of combining multiple differently configured FREEs in parallel to achieve fully controllable multi-dimensional soft actuation. To this end, we propose a novel methodology to represent and calculate the generalized forces generated by soft actuators as a function of their internal pressure. This methodology relies on the notion of a state dependent fluid Jacobian that yields a linear expression for force. We employ this concept to construct the set of all possible forces that can be generated by a soft system in a given state. This force zonotope can be used to inform the design and control of parallel combinations of soft actuators. The approach is verified experimentally with the parallel combination of three carefully designed actuators constrained to a 2DOF testing rig. The force predictions matched measured values with a root-mean-square error of less than 1.5 N force and 8 x 10^(-3)Nm moment, demonstrating the utility of the presented methodology.

* Published in IEEE Robotics and Automation Letters

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge