Zechen Xiong

CarbonFish -- A Bistable Underactuated Compliant Fish Robot capable of High Frequency Undulation

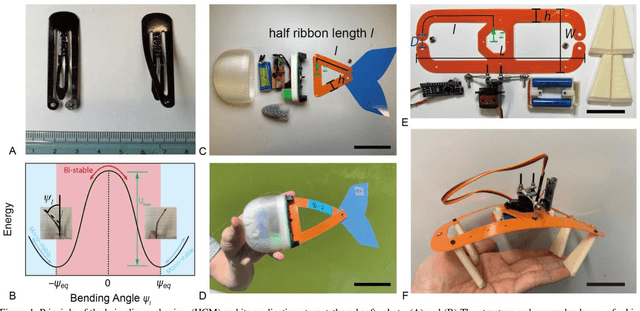

Nov 06, 2023Abstract:The Hair Clip Mechanism HCM represents an innovative in plane prestressed bistable mechanism, as delineated in our preceding studies, devised to augment the functional prowess of soft robotics. When juxtaposed with conventional soft and compliant robotic systems, HCMs exhibit pronounced rigidity, augmented mobility, reproducible repeatability, and an effective design and fabrication paradigm. In this research, we investigate the feasibility of utilizing carbon fiber reinforced plastic CFRP as the foundational material for an HCM based fish robot, herein referred to as CarbonFish. Our objective centers on realizing high frequency undulatory motion, thereby laying the groundwork for accelerated aquatic locomotion in subsequent models. We proffer an exhaustive design and fabrication schema underpinned by mathematical principles. Preliminary evaluations of our single actuated CarbonFish have evidenced an undulation frequency approaching 10 Hz, suggesting its potential to outperform other biologically inspired aquatic entities as well as real fish.

Designing a Hair-Clip Inspired Bistable Mechanism for Soft Fish Robots

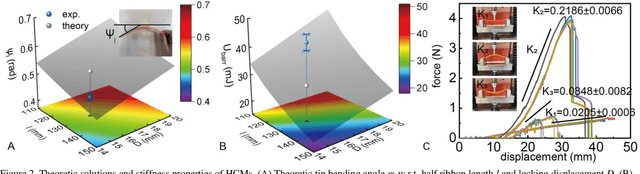

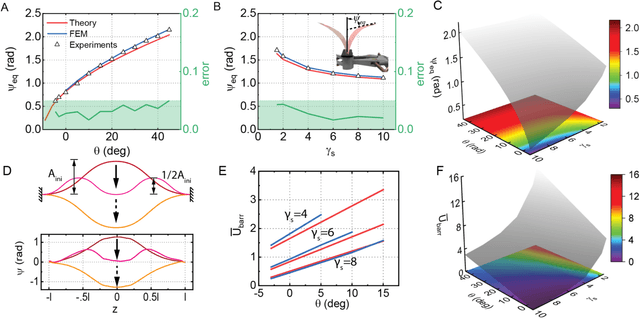

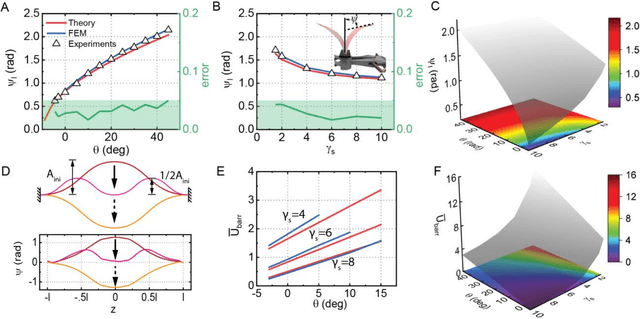

Nov 06, 2023Abstract:The Hair clip mechanism (HCM) is an in-plane prestressed bistable mechanism proposed in our previous research [1]~[5] to enhance the functionality of soft robotics. HCMs have several advantages, such as high rigidity, high mobility, good repeatability, and design and fabrication simplicity, compared to existing soft and compliant robotics. Using our experience with fish robots, this work delves into designing a novel HCM robotic propulsion system made from PETG plastic, carbon fiber-reinforced plastic (CFRP), and steel. Detailed derivation and verification of the HCM theory are given, and the influence of key parameters like dimensions, material types, and servo motor specifications are summarized. The designing algorithm offers insight into HCM robotics. It enables us to search for suitable components, operate robots at a desired frequency, and achieve high-frequency and high-speed undulatory swimming for fish robots.

Accelerating Aquatic Soft Robots with Elastic Instability Effects

Oct 21, 2023

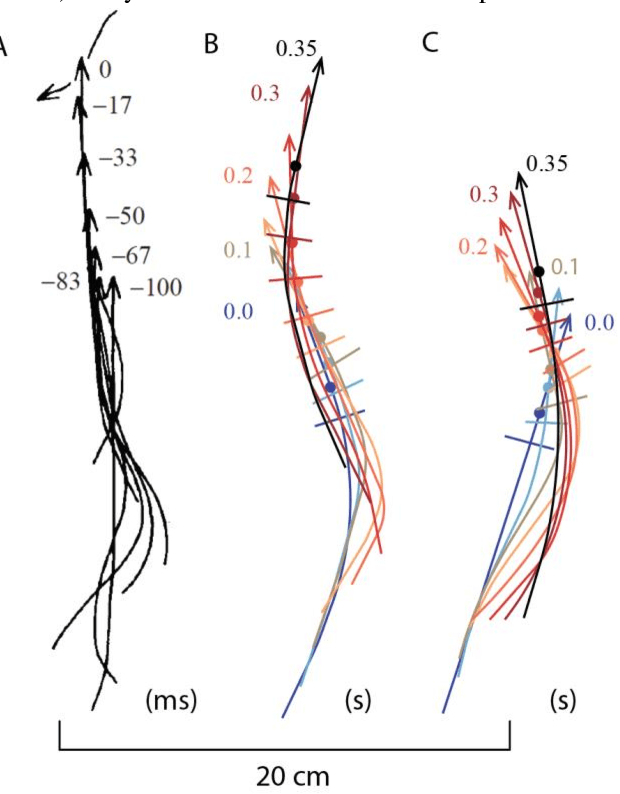

Abstract:Sinusoidal undulation has long been considered the most successful swimming pattern for fish and bionic aquatic robots [1]. However, a swimming pattern generated by the hair clip mechanism (HCM, part iii, Figure 1A) [2]~[5] may challenge this knowledge. HCM is an in-plane prestressed bi-stable mechanism that stores elastic energy and releases the stored energy quickly via its snap-through buckling. When used for fish robots, the HCM functions as the fish body and creates unique swimming patterns that we term HCM undulation. With the same energy consumption [3], HCM fish outperforms the traditionally designed soft fish with a two-fold increase in cruising speed. We reproduce this phenomenon in a single-link simulation with Aquarium [6]. HCM undulation generates an average propulsion of 16.7 N/m, 2-3 times larger than the reference undulation (6.78 N/m), sine pattern (5.34 N/m/s), and cambering sine pattern (6.36 N/m), and achieves an efficiency close to the sine pattern. These results can aid in developing fish robots and faster swimming patterns.

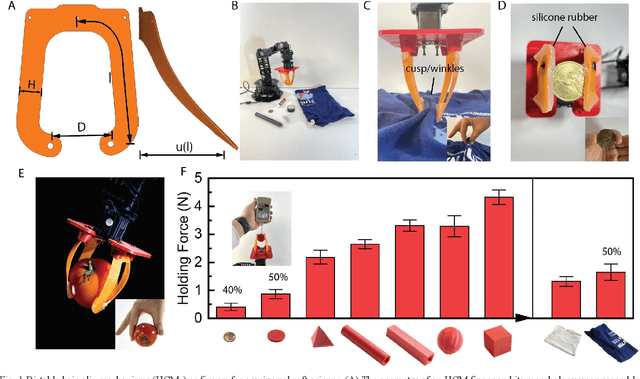

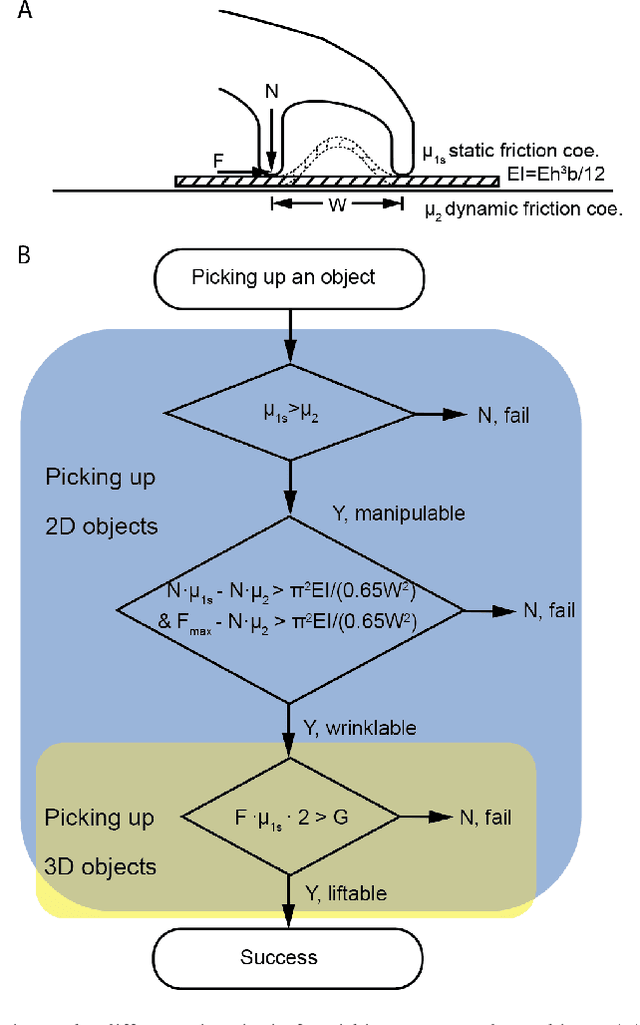

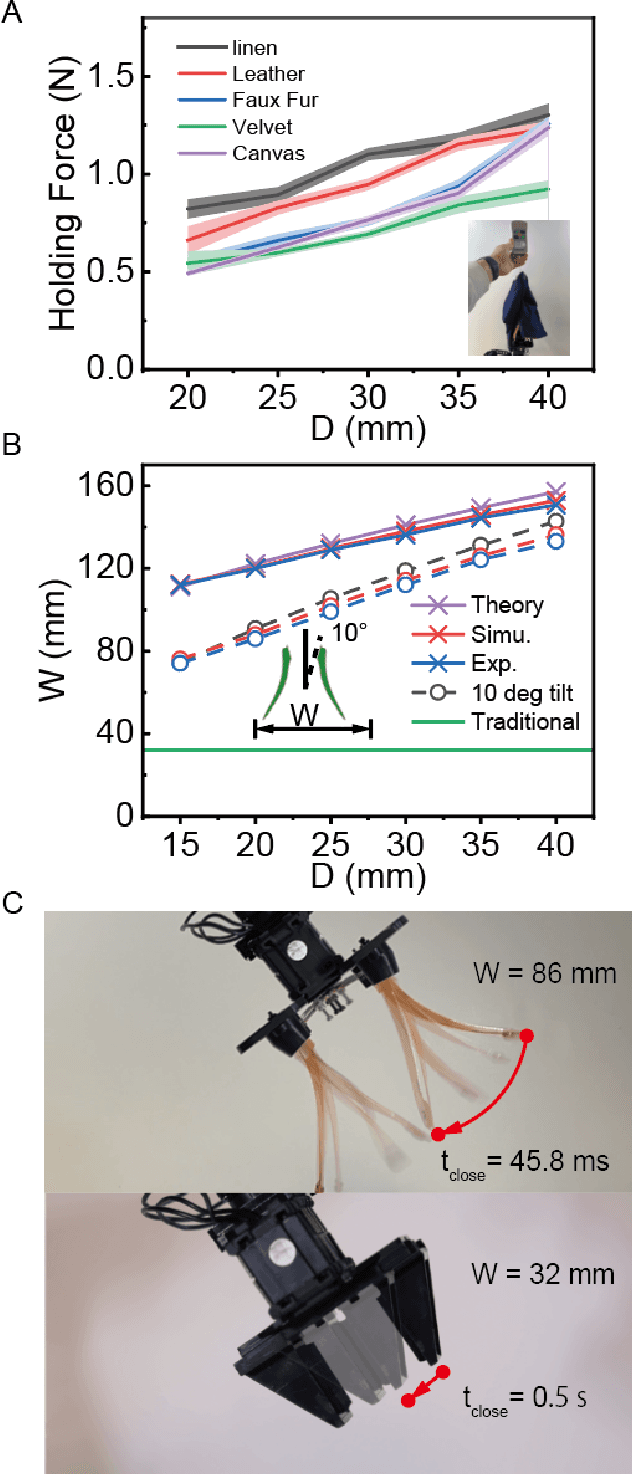

Rapid grasping of fabric using bionic soft grippers with elastic instability

Jan 26, 2023

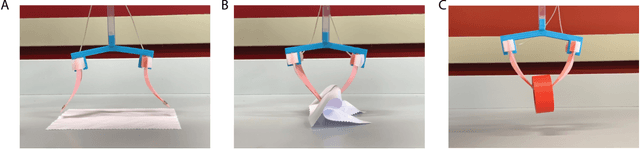

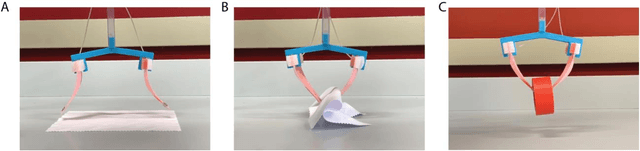

Abstract:Robot grasping is subject to an inherent tradeoff: Grippers with a large span typically take a longer time to close, and fast grippers usually cover a small span. However, many practical applications of soft grippers require the ability to close a large distance rapidly. For example, grasping cloth typically requires pressing a wide span of fabric into a graspable cusp. Here, we demonstrate a human-finger-inspired snapping gripper that exploits elastic instability to achieve reversible rapid closure over a wide span. Using prestressed semi-rigid material as the skeleton, the gripper fingers can widely open (86 ~) and rapidly close (46 ms) following a trajectory similar to that of a thumb-index finger pinching which is 2.7 times and 10.9 times better than the reference gripper in terms of span and speed, respectively. We theoretically give the design principle, simulatively verify the method, and experimentally test this gripper on a variety of rigid, flexible, and limp objects and achieve good adaptivity and mechanical performance. This research helps bridge the gap between strong industry manipulators and safe human-interactive robotic hands.

Fast Untethered Soft Robotic Crawler with Elastic Instability

Oct 05, 2022

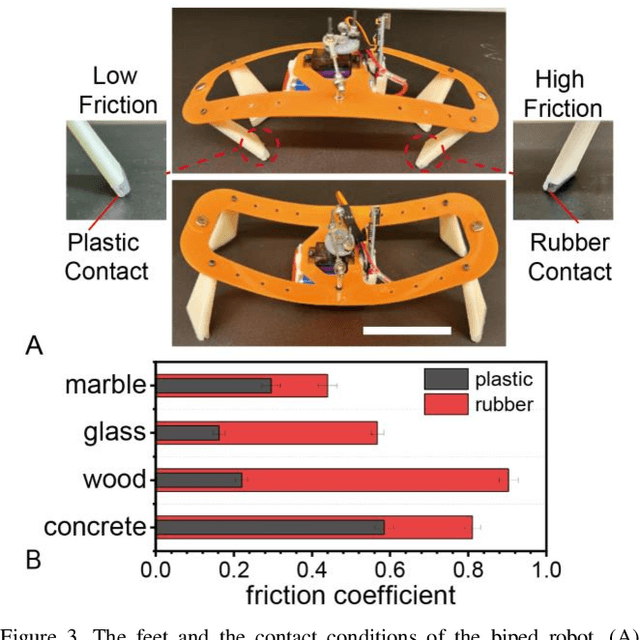

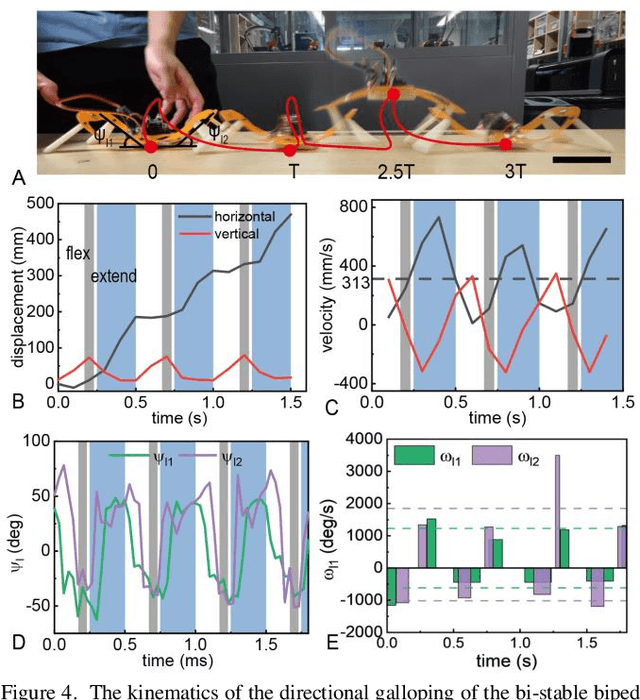

Abstract:High-speed locomotion of animals gives them tremendous advantages in exploring, hunting, and escaping from predators in varying environments. Enlightened by the fast-running gait of mammals like cheetahs and wolves, we designed and fabricated a single-servo-driving untethered soft robot that is capable of galloping at a speed of 313 mm/s or 1.56 body length per second (BL/s), 5.2 times and 2.6 times faster than the reported fastest predecessors in mm/s and BL/s, respectively, in literature. An in-plane prestressed hair clip mechanism (HCM) made up of semi-rigid materials like plastic is used as the supporting chassis, the compliant spine, and the muscle force amplifier of the robot at the same time, enabling the robot to be rapid and strong. The influence of factors including actuation frequency, substrates, tethering/untethering, and symmetric/asymmetric actuation is explored with experiments. Based on previous work, this paper further demonstrated the potential of HCM in addressing the speed problem of soft robots.

In-plane prestressed hair clip mechanism for the fastest untethered compliant fish robot

Jul 18, 2022

Abstract:A trend has emerged over the past decades pointing to the harnessing of structural instability in movable, programmable, and transformable mechanisms. Inspired by a steel hair clip, we combine the in-plane assembly with a bistable structure and build a compliant flapping mechanism using semi-rigid plastic sheets and installed it on both a tethered pneumatic soft robotic fish and an untethered motor-driven one to demonstrate its unprecedented advantages. Designing rules are proposed following the theories and verification. A two-fold increase in the swimming speed of the pneumatic fish compared to the reference is observed and the further study of the untether fish demonstrates a record-breaking velocity of 2.03 BL/s (43.6 cm/s) for the untethered compliant swimmer, outperforming the previously report fastest one with a significant margin of 194%. This work probably heralds a structural revolution for next-generation compliant robotics.

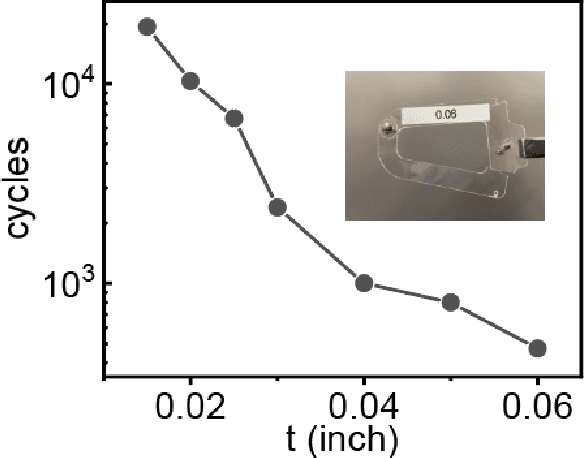

In-plane prestressing: Inspiration from a hair clip

Jun 29, 2022

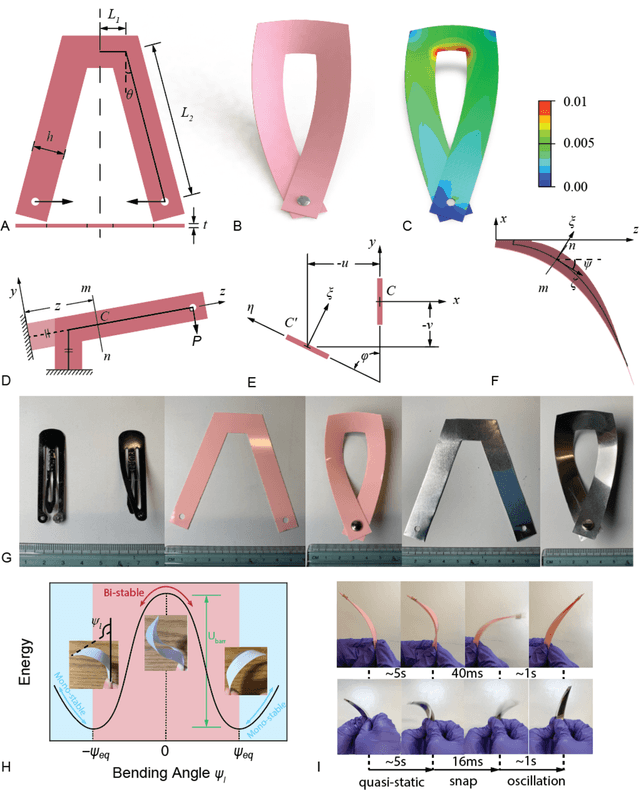

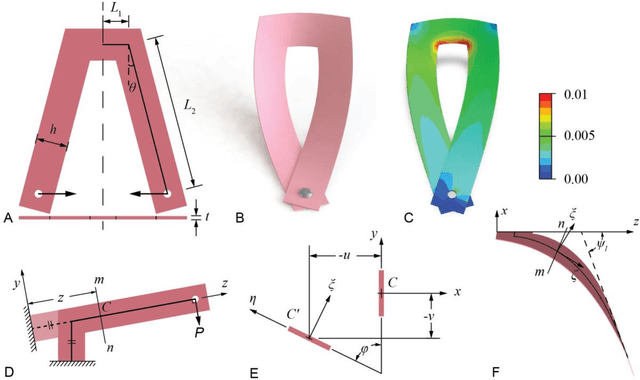

Abstract:Structural instability is a hazard that leads to catastrophic failure and is generally avoided through special designs. A trend, however, has emerged over the past decades pointing to the harnessing of mechanisms with instability. Inspired by the snapping of a hair clip, we are finessing the unique characteristics of the lateral-torsional buckling of beams and the snap-through of pre-buckled dome-like thin-wall structures in a new field: the in-plane prestressed mechanism. Analyses reveal how the 2D-3D assembly of an in-plane prestressed actuator (IPA) is achieved and how the post-buckling energy landscape is pictured. Combining them with soft robotics, we show that the inclusion of a bistable IPA can enormously enhance the performance of an underwater fish robot as well as inspire a finger-like soft gripper.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge