Yaoyao Fiona Zhao

The Economic Dispatch of Power-to-Gas Systems with Deep Reinforcement Learning:Tackling the Challenge of Delayed Rewards with Long-Term Energy Storage

Jun 06, 2025Abstract:Power-to-Gas (P2G) technologies gain recognition for enabling the integration of intermittent renewables, such as wind and solar, into electricity grids. However, determining the most cost-effective operation of these systems is complex due to the volatile nature of renewable energy, electricity prices, and loads. Additionally, P2G systems are less efficient in converting and storing energy compared to battery energy storage systems (BESs), and the benefits of converting electricity into gas are not immediately apparent. Deep Reinforcement Learning (DRL) has shown promise in managing the operation of energy systems amidst these uncertainties. Yet, DRL techniques face difficulties with the delayed reward characteristic of P2G system operation. Previous research has mostly focused on short-term studies that look at the energy conversion process, neglecting the long-term storage capabilities of P2G. This study presents a new method by thoroughly examining how DRL can be applied to the economic operation of P2G systems, in combination with BESs and gas turbines, over extended periods. Through three progressively more complex case studies, we assess the performance of DRL algorithms, specifically Deep Q-Networks and Proximal Policy Optimization, and introduce modifications to enhance their effectiveness. These modifications include integrating forecasts, implementing penalties on the reward function, and applying strategic cost calculations, all aimed at addressing the issue of delayed rewards. Our findings indicate that while DRL initially struggles with the complex decision-making required for P2G system operation, the adjustments we propose significantly improve its capability to devise cost-effective operation strategies, thereby unlocking the potential for long-term energy storage in P2G technologies.

A Lightweight Multi-Expert Generative Language Model System for Engineering Information and Knowledge Extraction

May 27, 2025Abstract:Despite recent advancements in domain adaptation techniques for large language models, these methods remain computationally intensive, and the resulting models can still exhibit hallucination issues. Most existing adaptation methods do not prioritize reducing the computational resources required for fine-tuning and inference of language models. Hallucination issues have gradually decreased with each new model release. However, they remain prevalent in engineering contexts, where generating well-structured text with minimal errors and inconsistencies is critical. This work introduces a novel approach called the Small Language Graph (SLG), which is a lightweight adaptation solution designed to address the two key challenges outlined above. The system is structured in the form of a graph, where each node represents a lightweight expert - a small language model fine-tuned on specific and concise texts. The results of this study have shown that SLG was able to surpass conventional fine-tuning methods on the Exact Match metric by 3 times. Additionally, the fine-tuning process was 1.7 times faster compared to that of a larger stand-alone language model. These findings introduce a potential for small to medium-sized engineering companies to confidently use generative AI technologies, such as LLMs, without the necessity to invest in expensive computational resources. Also, the graph architecture and the small size of expert nodes offer a possible opportunity for distributed AI systems, thus potentially diverting the global need for expensive centralized compute clusters.

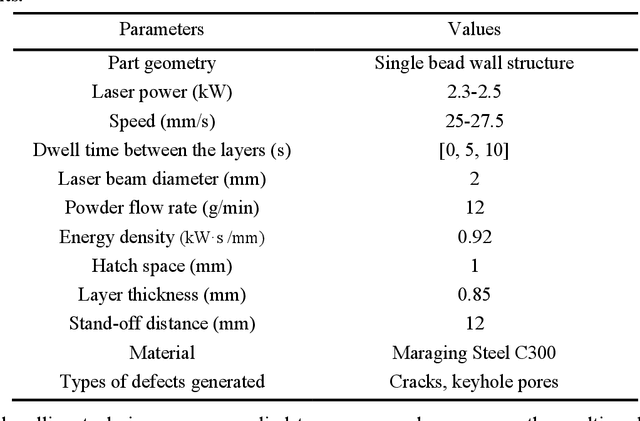

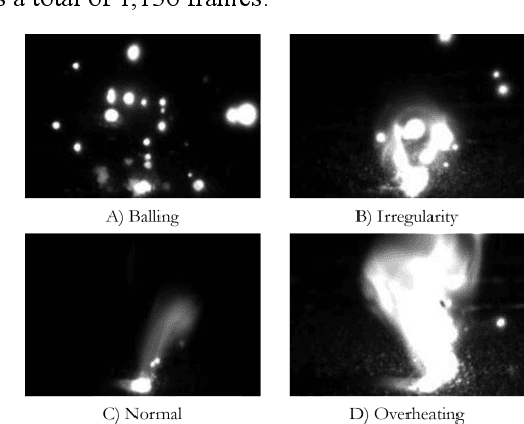

Redundancy Analysis and Mitigation for Machine Learning-Based Process Monitoring of Additive Manufacturing

Apr 30, 2025Abstract:The deployment of machine learning (ML)-based process monitoring systems has significantly advanced additive manufacturing (AM) by enabling real-time defect detection, quality assessment, and process optimization. However, redundancy is a critical yet often overlooked challenge in the deployment and operation of ML-based AM process monitoring systems. Excessive redundancy leads to increased equipment costs, compromised model performance, and high computational requirements, posing barriers to industrial adoption. However, existing research lacks a unified definition of redundancy and a systematic framework for its evaluation and mitigation. This paper defines redundancy in ML-based AM process monitoring and categorizes it into sample-level, feature-level, and model-level redundancy. A comprehensive multi-level redundancy mitigation (MLRM) framework is proposed, incorporating advanced methods such as data registration, downscaling, cross-modality knowledge transfer, and model pruning to systematically reduce redundancy while improving model performance. The framework is validated through an ML-based in-situ defect detection case study for directed energy deposition (DED), demonstrating a 91% reduction in latency, a 47% decrease in error rate, and a 99.4% reduction in storage requirements. Additionally, the proposed approach lowers sensor costs and energy consumption, enabling a lightweight, cost-effective, and scalable monitoring system. By defining redundancy and introducing a structured mitigation framework, this study establishes redundancy analysis and mitigation as a key enabler of efficient ML-based process monitoring in production environments.

Economic Battery Storage Dispatch with Deep Reinforcement Learning from Rule-Based Demonstrations

Apr 06, 2025

Abstract:The application of deep reinforcement learning algorithms to economic battery dispatch problems has significantly increased recently. However, optimizing battery dispatch over long horizons can be challenging due to delayed rewards. In our experiments we observe poor performance of popular actor-critic algorithms when trained on yearly episodes with hourly resolution. To address this, we propose an approach extending soft actor-critic (SAC) with learning from demonstrations. The special feature of our approach is that, due to the absence of expert demonstrations, the demonstration data is generated through simple, rule-based policies. We conduct a case study on a grid-connected microgrid and use if-then-else statements based on the wholesale price of electricity to collect demonstrations. These are stored in a separate replay buffer and sampled with linearly decaying probability along with the agent's own experiences. Despite these minimal modifications and the imperfections in the demonstration data, the results show a drastic performance improvement regarding both sample efficiency and final rewards. We further show that the proposed method reliably outperforms the demonstrator and is robust to the choice of rule, as long as the rule is sufficient to guide early training into the right direction.

Enhancing Battery Storage Energy Arbitrage with Deep Reinforcement Learning and Time-Series Forecasting

Oct 25, 2024

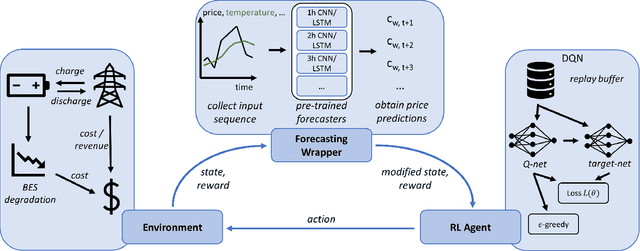

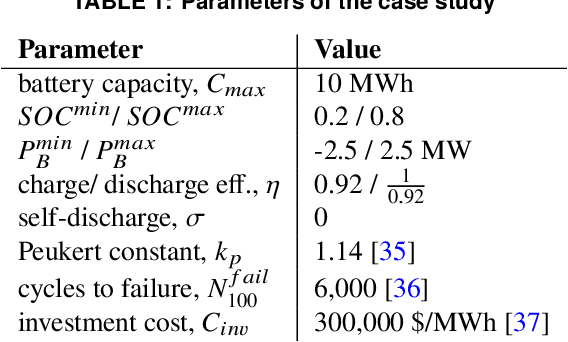

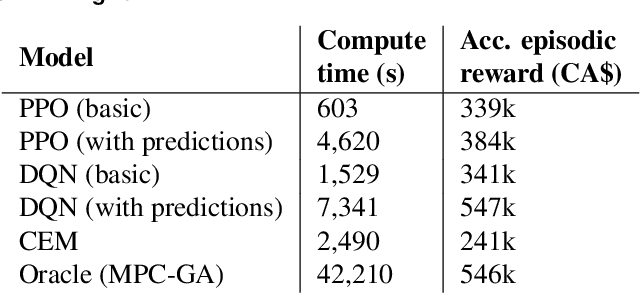

Abstract:Energy arbitrage is one of the most profitable sources of income for battery operators, generating revenues by buying and selling electricity at different prices. Forecasting these revenues is challenging due to the inherent uncertainty of electricity prices. Deep reinforcement learning (DRL) emerged in recent years as a promising tool, able to cope with uncertainty by training on large quantities of historical data. However, without access to future electricity prices, DRL agents can only react to the currently observed price and not learn to plan battery dispatch. Therefore, in this study, we combine DRL with time-series forecasting methods from deep learning to enhance the performance on energy arbitrage. We conduct a case study using price data from Alberta, Canada that is characterized by irregular price spikes and highly non-stationary. This data is challenging to forecast even when state-of-the-art deep learning models consisting of convolutional layers, recurrent layers, and attention modules are deployed. Our results show that energy arbitrage with DRL-enabled battery control still significantly benefits from these imperfect predictions, but only if predictors for several horizons are combined. Grouping multiple predictions for the next 24-hour window, accumulated rewards increased by 60% for deep Q-networks (DQN) compared to the experiments without forecasts. We hypothesize that multiple predictors, despite their imperfections, convey useful information regarding the future development of electricity prices through a "majority vote" principle, enabling the DRL agent to learn more profitable control policies.

Audio-visual cross-modality knowledge transfer for machine learning-based in-situ monitoring in laser additive manufacturing

Aug 09, 2024

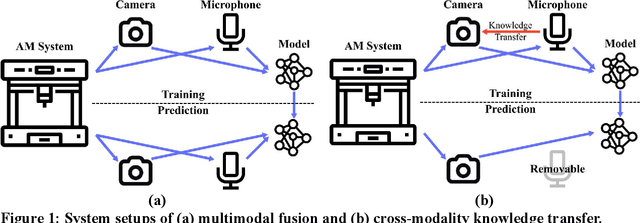

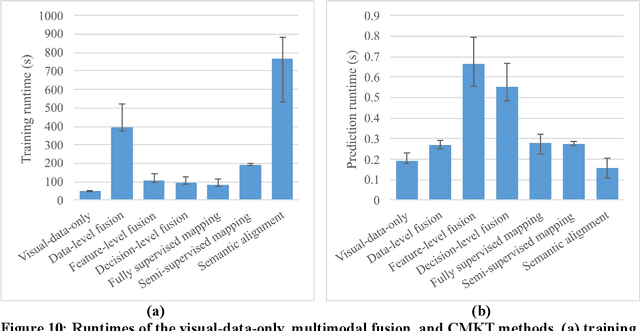

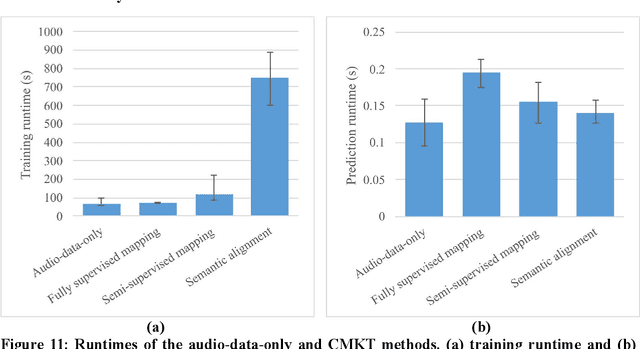

Abstract:Various machine learning (ML)-based in-situ monitoring systems have been developed to detect laser additive manufacturing (LAM) process anomalies and defects. Multimodal fusion can improve in-situ monitoring performance by acquiring and integrating data from multiple modalities, including visual and audio data. However, multimodal fusion employs multiple sensors of different types, which leads to higher hardware, computational, and operational costs. This paper proposes a cross-modality knowledge transfer (CMKT) methodology that transfers knowledge from a source to a target modality for LAM in-situ monitoring. CMKT enhances the usefulness of the features extracted from the target modality during the training phase and removes the sensors of the source modality during the prediction phase. This paper proposes three CMKT methods: semantic alignment, fully supervised mapping, and semi-supervised mapping. Semantic alignment establishes a shared encoded space between modalities to facilitate knowledge transfer. It utilizes a semantic alignment loss to align the distributions of the same classes (e.g., visual defective and audio defective classes) and a separation loss to separate the distributions of different classes (e.g., visual defective and audio defect-free classes). The two mapping methods transfer knowledge by deriving the features of one modality from the other modality using fully supervised and semi-supervised learning. The proposed CMKT methods were implemented and compared with multimodal audio-visual fusion in an LAM in-situ anomaly detection case study. The semantic alignment method achieves a 98.4% accuracy while removing the audio modality during the prediction phase, which is comparable to the accuracy of multimodal fusion (98.2%).

Human-artificial intelligence teaming for scientific information extraction from data-driven additive manufacturing research using large language models

Jul 26, 2024

Abstract:Data-driven research in Additive Manufacturing (AM) has gained significant success in recent years. This has led to a plethora of scientific literature to emerge. The knowledge in these works consists of AM and Artificial Intelligence (AI) contexts that have not been mined and formalized in an integrated way. It requires substantial effort and time to extract scientific information from these works. AM domain experts have contributed over two dozen review papers to summarize these works. However, information specific to AM and AI contexts still requires manual effort to extract. The recent success of foundation models such as BERT (Bidirectional Encoder Representations for Transformers) or GPT (Generative Pre-trained Transformers) on textual data has opened the possibility of expediting scientific information extraction. We propose a framework that enables collaboration between AM and AI experts to continuously extract scientific information from data-driven AM literature. A demonstration tool is implemented based on the proposed framework and a case study is conducted to extract information relevant to the datasets, modeling, sensing, and AM system categories. We show the ability of LLMs (Large Language Models) to expedite the extraction of relevant information from data-driven AM literature. In the future, the framework can be used to extract information from the broader design and manufacturing literature in the engineering discipline.

Transferability analysis of data-driven additive manufacturing knowledge: a case study between powder bed fusion and directed energy deposition

Sep 12, 2023Abstract:Data-driven research in Additive Manufacturing (AM) has gained significant success in recent years. This has led to a plethora of scientific literature to emerge. The knowledge in these works consists of AM and Artificial Intelligence (AI) contexts that have not been mined and formalized in an integrated way. Moreover, no tools or guidelines exist to support data-driven knowledge transfer from one context to another. As a result, data-driven solutions using specific AI techniques are being developed and validated only for specific AM process technologies. There is a potential to exploit the inherent similarities across various AM technologies and adapt the existing solutions from one process or problem to another using AI, such as Transfer Learning. We propose a three-step knowledge transferability analysis framework in AM to support data-driven AM knowledge transfer. As a prerequisite to transferability analysis, AM knowledge is featurized into identified knowledge components. The framework consists of pre-transfer, transfer, and post-transfer steps to accomplish knowledge transfer. A case study is conducted between flagship metal AM processes. Laser Powder Bed Fusion (LPBF) is the source of knowledge motivated by its relative matureness in applying AI over Directed Energy Deposition (DED), which drives the need for knowledge transfer as the less explored target process. We show successful transfer at different levels of the data-driven solution, including data representation, model architecture, and model parameters. The pipeline of AM knowledge transfer can be automated in the future to allow efficient cross-context or cross-process knowledge exchange.

Optimal Economic Gas Turbine Dispatch with Deep Reinforcement Learning

Aug 28, 2023

Abstract:Dispatching strategies for gas turbines (GTs) are changing in modern electricity grids. A growing incorporation of intermittent renewable energy requires GTs to operate more but shorter cycles and more frequently on partial loads. Deep reinforcement learning (DRL) has recently emerged as a tool that can cope with this development and dispatch GTs economically. The key advantages of DRL are a model-free optimization and the ability to handle uncertainties, such as those introduced by varying loads or renewable energy production. In this study, three popular DRL algorithms are implemented for an economic GT dispatch problem on a case study in Alberta, Canada. We highlight the benefits of DRL by incorporating an existing thermodynamic software provided by Siemens Energy into the environment model and by simulating uncertainty via varying electricity prices, loads, and ambient conditions. Among the tested algorithms and baseline methods, Deep Q-Networks (DQN) obtained the highest rewards while Proximal Policy Optimization (PPO) was the most sample efficient. We further propose and implement a method to assign GT operation and maintenance cost dynamically based on operating hours and cycles. Compared to existing methods, our approach better approximates the true cost of modern GT dispatch and hence leads to more realistic policies.

Evaluation of Key Spatiotemporal Learners for Print Track Anomaly Classification Using Melt Pool Image Streams

Aug 28, 2023

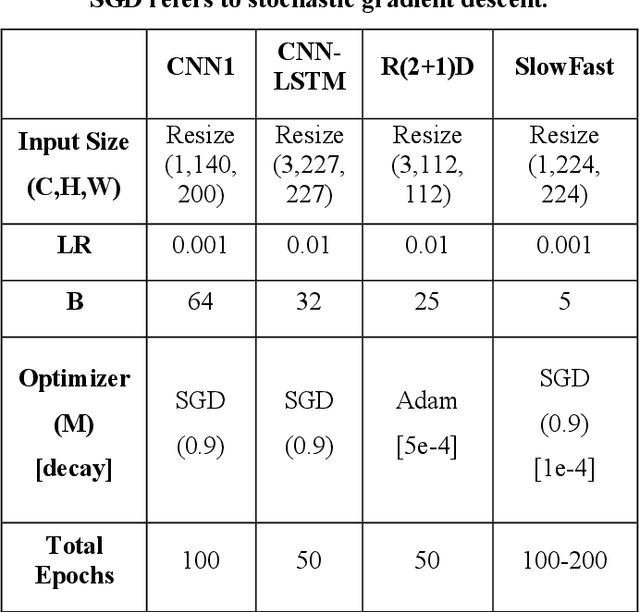

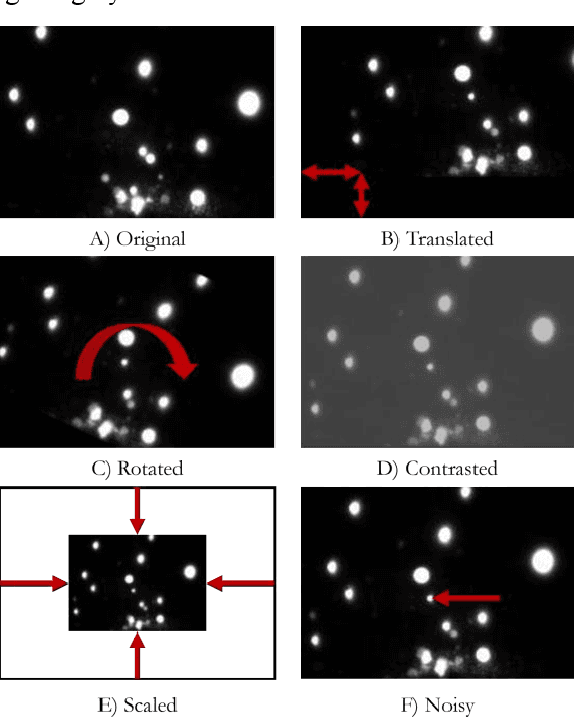

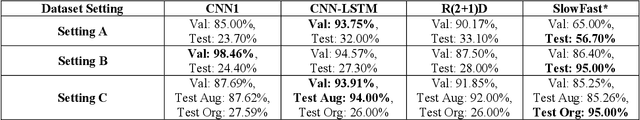

Abstract:Recent applications of machine learning in metal additive manufacturing (MAM) have demonstrated significant potential in addressing critical barriers to the widespread adoption of MAM technology. Recent research in this field emphasizes the importance of utilizing melt pool signatures for real-time defect prediction. While high-quality melt pool image data holds the promise of enabling precise predictions, there has been limited exploration into the utilization of cutting-edge spatiotemporal models that can harness the inherent transient and sequential characteristics of the additive manufacturing process. This research introduces and puts into practice some of the leading deep spatiotemporal learning models that can be adapted for the classification of melt pool image streams originating from various materials, systems, and applications. Specifically, it investigates two-stream networks comprising spatial and temporal streams, a recurrent spatial network, and a factorized 3D convolutional neural network. The capacity of these models to generalize when exposed to perturbations in melt pool image data is examined using data perturbation techniques grounded in real-world process scenarios. The implemented architectures demonstrate the ability to capture the spatiotemporal features of melt pool image sequences. However, among these models, only the Kinetics400 pre-trained SlowFast network, categorized as a two-stream network, exhibits robust generalization capabilities in the presence of data perturbations.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge