Jiarui Xie

Redundancy Analysis and Mitigation for Machine Learning-Based Process Monitoring of Additive Manufacturing

Apr 30, 2025Abstract:The deployment of machine learning (ML)-based process monitoring systems has significantly advanced additive manufacturing (AM) by enabling real-time defect detection, quality assessment, and process optimization. However, redundancy is a critical yet often overlooked challenge in the deployment and operation of ML-based AM process monitoring systems. Excessive redundancy leads to increased equipment costs, compromised model performance, and high computational requirements, posing barriers to industrial adoption. However, existing research lacks a unified definition of redundancy and a systematic framework for its evaluation and mitigation. This paper defines redundancy in ML-based AM process monitoring and categorizes it into sample-level, feature-level, and model-level redundancy. A comprehensive multi-level redundancy mitigation (MLRM) framework is proposed, incorporating advanced methods such as data registration, downscaling, cross-modality knowledge transfer, and model pruning to systematically reduce redundancy while improving model performance. The framework is validated through an ML-based in-situ defect detection case study for directed energy deposition (DED), demonstrating a 91% reduction in latency, a 47% decrease in error rate, and a 99.4% reduction in storage requirements. Additionally, the proposed approach lowers sensor costs and energy consumption, enabling a lightweight, cost-effective, and scalable monitoring system. By defining redundancy and introducing a structured mitigation framework, this study establishes redundancy analysis and mitigation as a key enabler of efficient ML-based process monitoring in production environments.

Audio-visual cross-modality knowledge transfer for machine learning-based in-situ monitoring in laser additive manufacturing

Aug 09, 2024

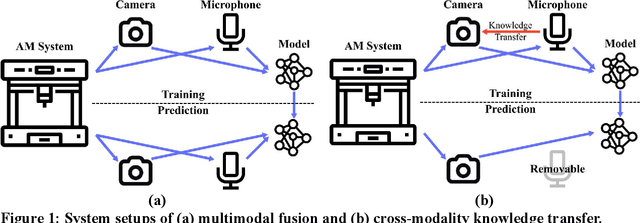

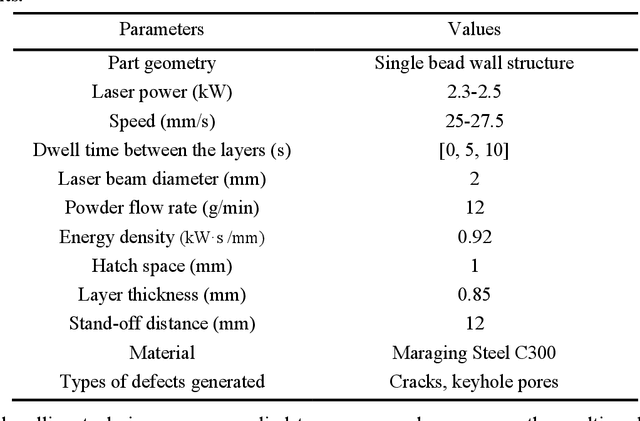

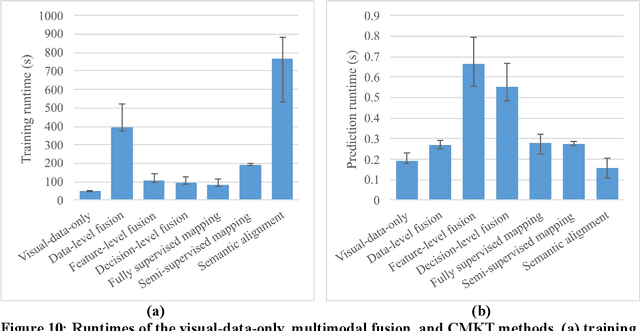

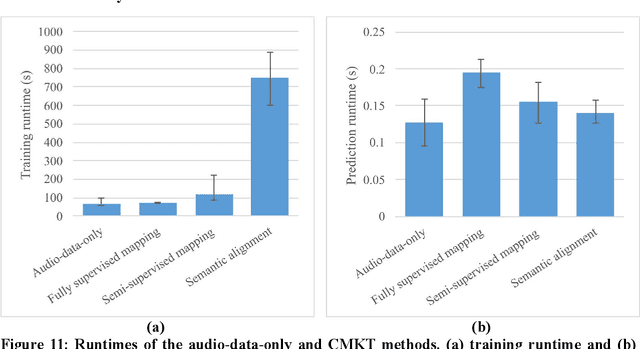

Abstract:Various machine learning (ML)-based in-situ monitoring systems have been developed to detect laser additive manufacturing (LAM) process anomalies and defects. Multimodal fusion can improve in-situ monitoring performance by acquiring and integrating data from multiple modalities, including visual and audio data. However, multimodal fusion employs multiple sensors of different types, which leads to higher hardware, computational, and operational costs. This paper proposes a cross-modality knowledge transfer (CMKT) methodology that transfers knowledge from a source to a target modality for LAM in-situ monitoring. CMKT enhances the usefulness of the features extracted from the target modality during the training phase and removes the sensors of the source modality during the prediction phase. This paper proposes three CMKT methods: semantic alignment, fully supervised mapping, and semi-supervised mapping. Semantic alignment establishes a shared encoded space between modalities to facilitate knowledge transfer. It utilizes a semantic alignment loss to align the distributions of the same classes (e.g., visual defective and audio defective classes) and a separation loss to separate the distributions of different classes (e.g., visual defective and audio defect-free classes). The two mapping methods transfer knowledge by deriving the features of one modality from the other modality using fully supervised and semi-supervised learning. The proposed CMKT methods were implemented and compared with multimodal audio-visual fusion in an LAM in-situ anomaly detection case study. The semantic alignment method achieves a 98.4% accuracy while removing the audio modality during the prediction phase, which is comparable to the accuracy of multimodal fusion (98.2%).

Human-artificial intelligence teaming for scientific information extraction from data-driven additive manufacturing research using large language models

Jul 26, 2024

Abstract:Data-driven research in Additive Manufacturing (AM) has gained significant success in recent years. This has led to a plethora of scientific literature to emerge. The knowledge in these works consists of AM and Artificial Intelligence (AI) contexts that have not been mined and formalized in an integrated way. It requires substantial effort and time to extract scientific information from these works. AM domain experts have contributed over two dozen review papers to summarize these works. However, information specific to AM and AI contexts still requires manual effort to extract. The recent success of foundation models such as BERT (Bidirectional Encoder Representations for Transformers) or GPT (Generative Pre-trained Transformers) on textual data has opened the possibility of expediting scientific information extraction. We propose a framework that enables collaboration between AM and AI experts to continuously extract scientific information from data-driven AM literature. A demonstration tool is implemented based on the proposed framework and a case study is conducted to extract information relevant to the datasets, modeling, sensing, and AM system categories. We show the ability of LLMs (Large Language Models) to expedite the extraction of relevant information from data-driven AM literature. In the future, the framework can be used to extract information from the broader design and manufacturing literature in the engineering discipline.

Transferability analysis of data-driven additive manufacturing knowledge: a case study between powder bed fusion and directed energy deposition

Sep 12, 2023Abstract:Data-driven research in Additive Manufacturing (AM) has gained significant success in recent years. This has led to a plethora of scientific literature to emerge. The knowledge in these works consists of AM and Artificial Intelligence (AI) contexts that have not been mined and formalized in an integrated way. Moreover, no tools or guidelines exist to support data-driven knowledge transfer from one context to another. As a result, data-driven solutions using specific AI techniques are being developed and validated only for specific AM process technologies. There is a potential to exploit the inherent similarities across various AM technologies and adapt the existing solutions from one process or problem to another using AI, such as Transfer Learning. We propose a three-step knowledge transferability analysis framework in AM to support data-driven AM knowledge transfer. As a prerequisite to transferability analysis, AM knowledge is featurized into identified knowledge components. The framework consists of pre-transfer, transfer, and post-transfer steps to accomplish knowledge transfer. A case study is conducted between flagship metal AM processes. Laser Powder Bed Fusion (LPBF) is the source of knowledge motivated by its relative matureness in applying AI over Directed Energy Deposition (DED), which drives the need for knowledge transfer as the less explored target process. We show successful transfer at different levels of the data-driven solution, including data representation, model architecture, and model parameters. The pipeline of AM knowledge transfer can be automated in the future to allow efficient cross-context or cross-process knowledge exchange.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge