Shunnosuke Yoshimura

M3D-skin: Multi-material 3D-printed Tactile Sensor with Hierarchical Infill Structures for Pressure Sensing

Oct 14, 2025Abstract:Tactile sensors have a wide range of applications, from utilization in robotic grippers to human motion measurement. If tactile sensors could be fabricated and integrated more easily, their applicability would further expand. In this study, we propose a tactile sensor-M3D-skin-that can be easily fabricated with high versatility by leveraging the infill patterns of a multi-material fused deposition modeling (FDM) 3D printer as the sensing principle. This method employs conductive and non-conductive flexible filaments to create a hierarchical structure with a specific infill pattern. The flexible hierarchical structure deforms under pressure, leading to a change in electrical resistance, enabling the acquisition of tactile information. We measure the changes in characteristics of the proposed tactile sensor caused by modifications to the hierarchical structure. Additionally, we demonstrate the fabrication and use of a multi-tile sensor. Furthermore, as applications, we implement motion pattern measurement on the sole of a foot, integration with a robotic hand, and tactile-based robotic operations. Through these experiments, we validate the effectiveness of the proposed tactile sensor.

Vlimb: A Wire-Driven Wearable Robot for Bodily Extension, Balancing Powerfulness and Reachability

Nov 14, 2024Abstract:Numerous wearable robots have been developed to meet the demands of physical assistance and entertainment. These wearable robots range from body-enhancing types that assist human arms and legs to body-extending types that have extra arms. This study focuses specifically on wearable robots of the latter category, aimed at bodily extension. However, they have not yet achieved the level of powerfulness and reachability equivalent to that of human limbs, limiting their application to entertainment and manipulation tasks involving lightweight objects. Therefore, in this study, we develop an body-extending wearable robot, Vlimb, which has enough powerfulness to lift a human and can perform manipulation. Leveraging the advantages of tendon-driven mechanisms, Vlimb incorporates a wire routing mechanism capable of accommodating both delicate manipulations and robust lifting tasks. Moreover, by introducing a passive ring structure to overcome the limited reachability inherent in tendon-driven mechanisms, Vlimb achieves both the powerfulness and reachability comparable to that of humans. This paper outlines the design methodology of Vlimb, conducts preliminary manipulation and lifting tasks, and verifies its effectiveness.

Patterned Structure Muscle : Arbitrary Shaped Wire-driven Artificial Muscle Utilizing Anisotropic Flexible Structure for Musculoskeletal Robots

Oct 10, 2024Abstract:Muscles of the human body are composed of tiny actuators made up of myosin and actin filaments. They can exert force in various shapes such as curved or flat, under contact forces and deformations from the environment. On the other hand, muscles in musculoskeletal robots so far have faced challenges in generating force in such shapes and environments. To address this issue, we propose Patterned Structure Muscle (PSM), artificial muscles for musculoskeletal robots. PSM utilizes patterned structures with anisotropic characteristics, wire-driven mechanisms, and is made of flexible material Thermoplastic Polyurethane (TPU) using FDM 3D printing. This method enables the creation of various shapes of muscles, such as simple 1 degree-of-freedom (DOF) muscles, Multi-DOF wide area muscles, joint-covering muscles, and branched muscles. We created an upper arm structure using these muscles to demonstrate wide range of motion, lifting heavy objects, and movements through environmental contact. These experiments show that the proposed PSM is capable of operating in various shapes and environments, and is suitable for the muscles of musculoskeletal robots.

Design Method of a Kangaroo Robot with High Power Legs and an Articulated Soft Tail

Oct 10, 2024Abstract:In this paper, we focus on the kangaroo, which has powerful legs capable of jumping and a soft and strong tail. To incorporate these unique structure into a robot for utilization, we propose a design method that takes into account both the feasibility as a robot and the kangaroo-mimetic structure. Based on the kangaroo's musculoskeletal structure, we determine the structure of the robot that enables it to jump by analyzing the muscle arrangement and prior verification in simulation. Also, to realize a tail capable of body support, we use an articulated, elastic structure as a tail. In order to achieve both softness and high power output, the robot is driven by a direct-drive, high-power wire-winding mechanism, and weight of legs and the tail is reduced by placing motors in the torso. The developed kangaroo robot can jump with its hind legs, moving its tail, and supporting its body using its hind legs and tail.

Construction of Musculoskeletal Simulation for Shoulder Complex with Ligaments and Its Validation via Model Predictive Control

Oct 08, 2024Abstract:The complex ways in which humans utilize their bodies in sports and martial arts are remarkable, and human motion analysis is one of the most effective tools for robot body design and control. On the other hand, motion analysis is not easy, and it is difficult to measure complex body motions in detail due to the influence of numerous muscles and soft tissues, mainly ligaments. In response, various musculoskeletal simulators have been developed and applied to motion analysis and robotics. However, none of them reproduce the ligaments but only the muscles, nor do they focus on the shoulder complex, including the clavicle and scapula, which is one of the most complex parts of the body. Therefore, in this study, a detailed simulation model of the shoulder complex including ligaments is constructed. The model will mimic not only the skeletal structure and muscle arrangement but also the ligament arrangement and maximum muscle strength. Through model predictive control based on the constructed simulation, we confirmed that the ligaments contribute to joint stabilization in the first movement and that the proper distribution of maximum muscle force contributes to the equalization of the load on each muscle, demonstrating the effectiveness of this simulation.

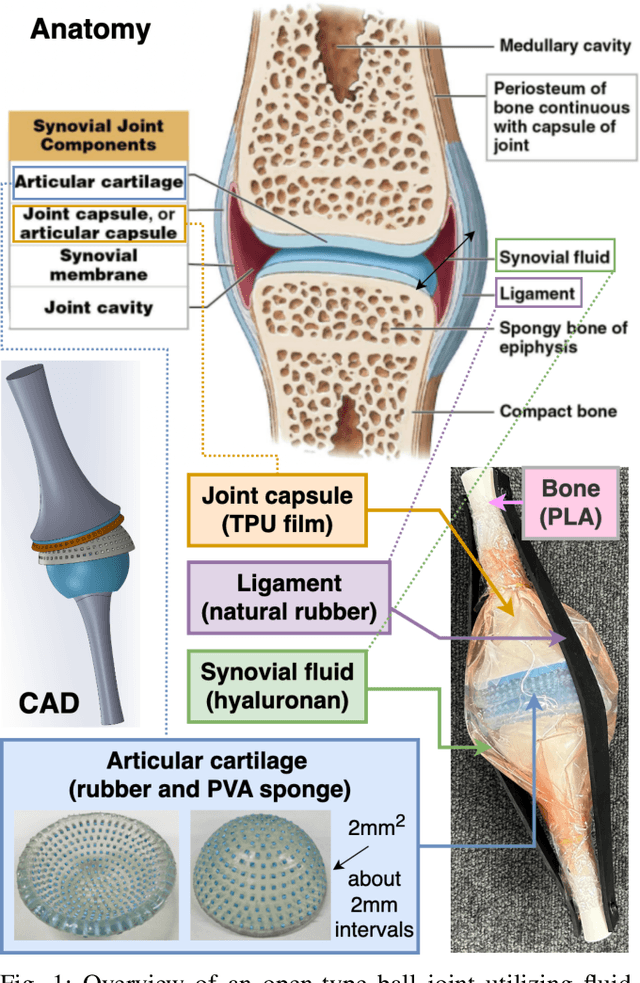

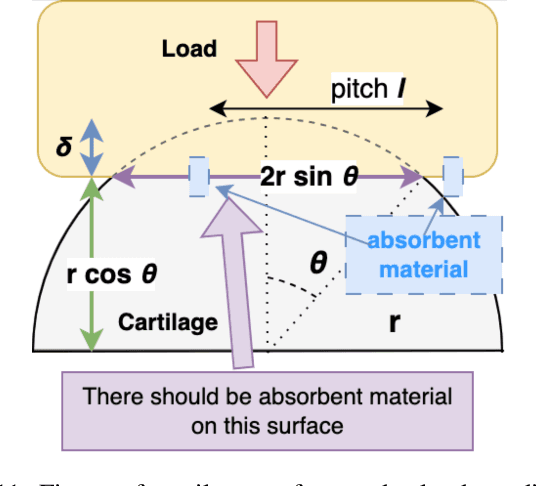

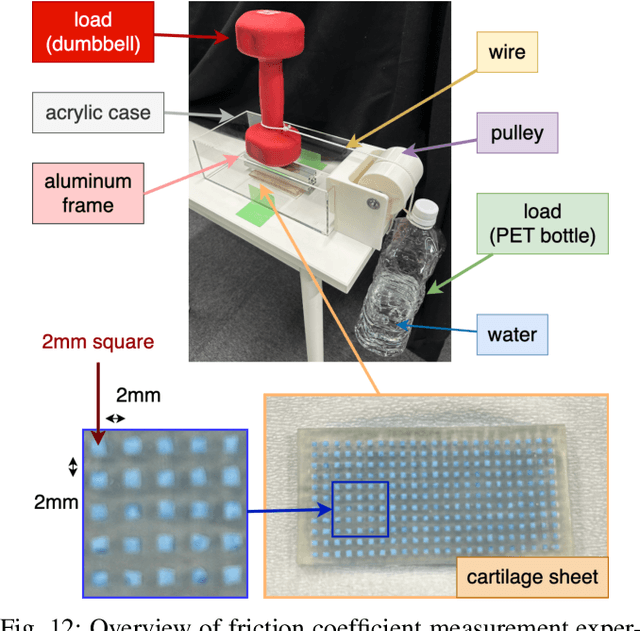

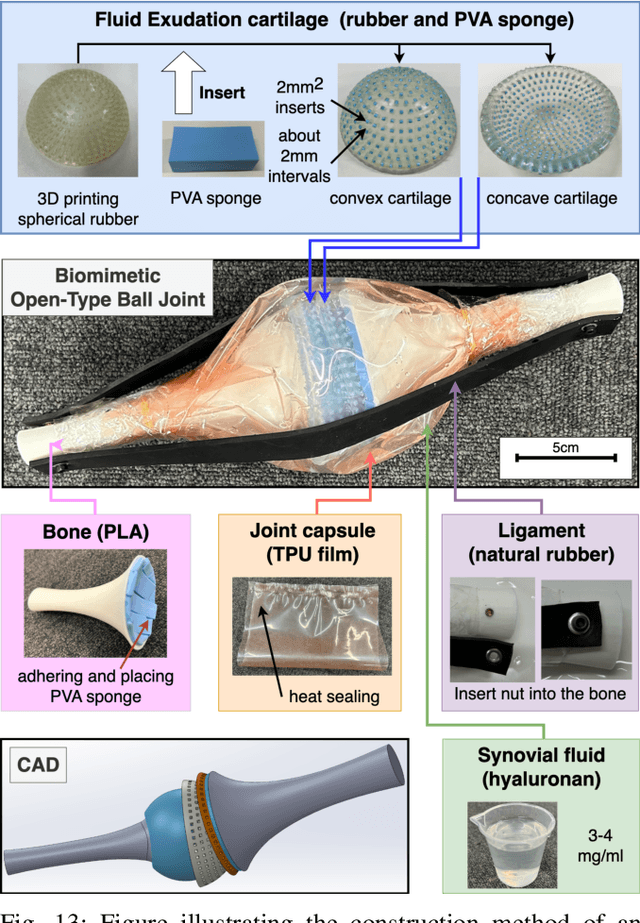

Designing Fluid-Exuding Cartilage for Biomimetic Robots Mimicking Human Joint Lubrication Function

Apr 10, 2024

Abstract:The human joint is an open-type joint composed of bones, cartilage, ligaments, synovial fluid, and joint capsule, having advantages of flexibility and impact resistance. However, replicating this structure in robots introduces friction challenges due to the absence of bearings. To address this, our study focuses on mimicking the fluid-exuding function of human cartilage. We employ a rubber-based 3D printing technique combined with absorbent materials to create a versatile and easily designed cartilage sheet for biomimetic robots. We evaluate both the fluid-exuding function and friction coefficient of the fabricated flat cartilage sheet. Furthermore, we practically create a piece of curved cartilage and an open-type biomimetic ball joint in combination with bones, ligaments, synovial fluid, and joint capsule to demonstrate the utility of the proposed cartilage sheet in the construction of such joints.

Design Optimization of Wire Arrangement with Variable Relay Points in Numerical Simulation for Tendon-driven Robots

Jan 05, 2024Abstract:One of the most important features of tendon-driven robots is the ease of wire arrangement and the degree of freedom it affords, enabling the construction of a body that satisfies the desired characteristics by modifying the wire arrangement. Various wire arrangement optimization methods have been proposed, but they have simplified the configuration by assuming that the moment arm of wires to joints are constant, or by disregarding wire arrangements that span multiple joints and include relay points. In this study, we formulate a more flexible wire arrangement optimization problem in which each wire is represented by a start point, multiple relay points, and an end point, and achieve the desired physical performance based on black-box optimization. We consider a multi-objective optimization which simultaneously takes into account both the feasible operational force space and velocity space, and discuss the optimization results obtained from various configurations.

* accepted at IEEE Robotics and Automation Letters (RA-L), website - https://haraduka.github.io/muscle-arrange-optimization/

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge