Yuta Sahara

Fundamental Three-Dimensional Configuration of Wire-Wound Muscle-Tendon Complex Drive

Nov 06, 2024Abstract:For robots to become more versatile and expand their areas of application, their bodies need to be suitable for contact with the environment. When the human body comes into contact with the environment, it is possible for it to continue to move even if the positional relationship between muscles or the shape of the muscles changes. We have already focused on the effect of geometric deformation of muscles and proposed a drive system called wire-wound Muscle-Tendon Complex (ww-MTC), an extension of the wire drive system. Our previous study using a robot with a two-dimensional configuration demonstrated several advantages: reduced wire loosening, interference, and wear; improved robustness during environmental contact; and a muscular appearance. However, this design had some problems, such as excessive muscle expansion that hindered inter-muscle movement, and confinement to planar motion. In this study, we develop the ww-MTC into a three-dimensional shape. We present a fundamental construction method for a muscle exterior that expands gently and can be contacted over its entire surface. We also apply the three-dimensional ww-MTC to a 2-axis 3-muscle robot, and confirm that the robot can continue to move while adapting to its environment.

CubiXMusashi: Fusion of Wire-Driven CubiX and Musculoskeletal Humanoid Musashi toward Unlimited Performance

Oct 31, 2024Abstract:Humanoids exhibit a wide variety in terms of joint configuration, actuators, and degrees of freedom, resulting in different achievable movements and tasks for each type. Particularly, musculoskeletal humanoids are developed to closely emulate human body structure and movement functions, consisting of a skeletal framework driven by numerous muscle actuators. The redundant arrangement of muscles relative to the skeletal degrees of freedom has been used to represent the flexible and complex body movements observed in humans. However, due to this flexible body and high degrees of freedom, modeling, simulation, and control become extremely challenging, limiting the feasible movements and tasks. In this study, we integrate the musculoskeletal humanoid Musashi with the wire-driven robot CubiX, capable of connecting to the environment, to form CubiXMusashi. This combination addresses the shortcomings of traditional musculoskeletal humanoids and enables movements beyond the capabilities of other humanoids. CubiXMusashi connects to the environment with wires and drives by winding them, successfully achieving movements such as pull-up, rising from a lying pose, and mid-air kicking, which are difficult for Musashi alone. This concept demonstrates that various humanoids, not limited to musculoskeletal humanoids, can mitigate their physical constraints and acquire new abilities by connecting to the environment and driving through wires.

Patterned Structure Muscle : Arbitrary Shaped Wire-driven Artificial Muscle Utilizing Anisotropic Flexible Structure for Musculoskeletal Robots

Oct 10, 2024Abstract:Muscles of the human body are composed of tiny actuators made up of myosin and actin filaments. They can exert force in various shapes such as curved or flat, under contact forces and deformations from the environment. On the other hand, muscles in musculoskeletal robots so far have faced challenges in generating force in such shapes and environments. To address this issue, we propose Patterned Structure Muscle (PSM), artificial muscles for musculoskeletal robots. PSM utilizes patterned structures with anisotropic characteristics, wire-driven mechanisms, and is made of flexible material Thermoplastic Polyurethane (TPU) using FDM 3D printing. This method enables the creation of various shapes of muscles, such as simple 1 degree-of-freedom (DOF) muscles, Multi-DOF wide area muscles, joint-covering muscles, and branched muscles. We created an upper arm structure using these muscles to demonstrate wide range of motion, lifting heavy objects, and movements through environmental contact. These experiments show that the proposed PSM is capable of operating in various shapes and environments, and is suitable for the muscles of musculoskeletal robots.

Construction of Musculoskeletal Simulation for Shoulder Complex with Ligaments and Its Validation via Model Predictive Control

Oct 08, 2024Abstract:The complex ways in which humans utilize their bodies in sports and martial arts are remarkable, and human motion analysis is one of the most effective tools for robot body design and control. On the other hand, motion analysis is not easy, and it is difficult to measure complex body motions in detail due to the influence of numerous muscles and soft tissues, mainly ligaments. In response, various musculoskeletal simulators have been developed and applied to motion analysis and robotics. However, none of them reproduce the ligaments but only the muscles, nor do they focus on the shoulder complex, including the clavicle and scapula, which is one of the most complex parts of the body. Therefore, in this study, a detailed simulation model of the shoulder complex including ligaments is constructed. The model will mimic not only the skeletal structure and muscle arrangement but also the ligament arrangement and maximum muscle strength. Through model predictive control based on the constructed simulation, we confirmed that the ligaments contribute to joint stabilization in the first movement and that the proper distribution of maximum muscle force contributes to the equalization of the load on each muscle, demonstrating the effectiveness of this simulation.

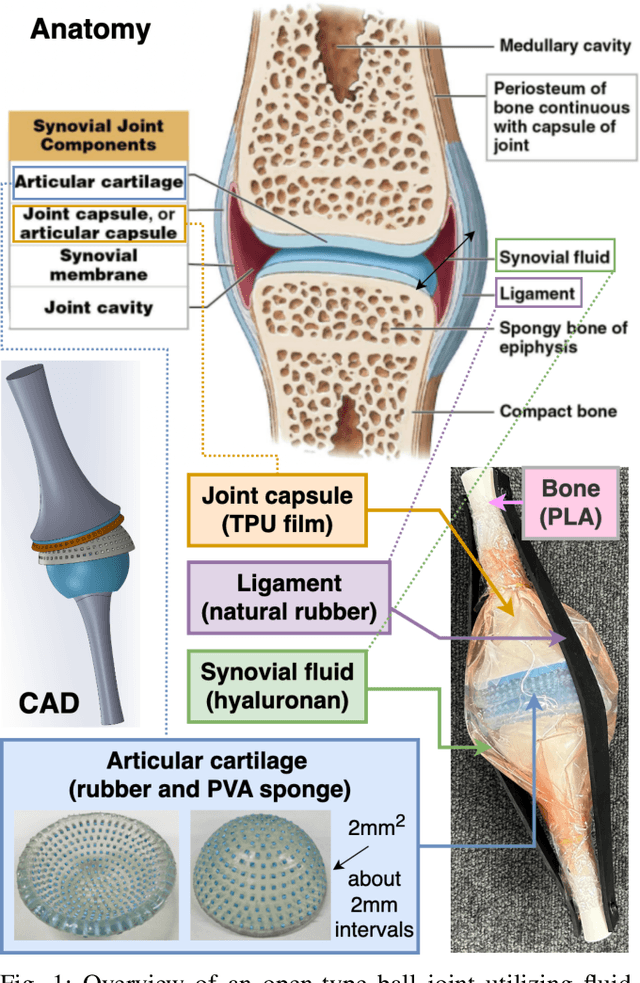

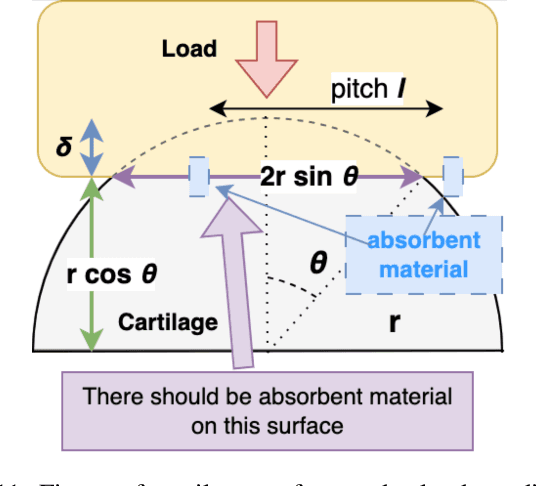

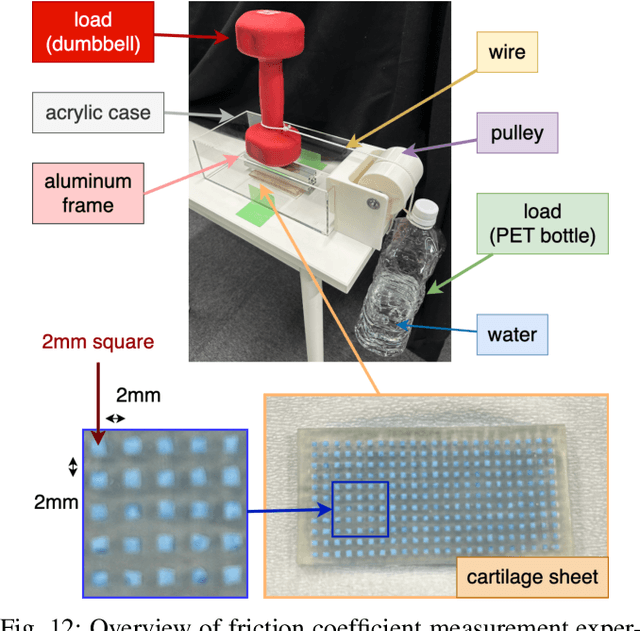

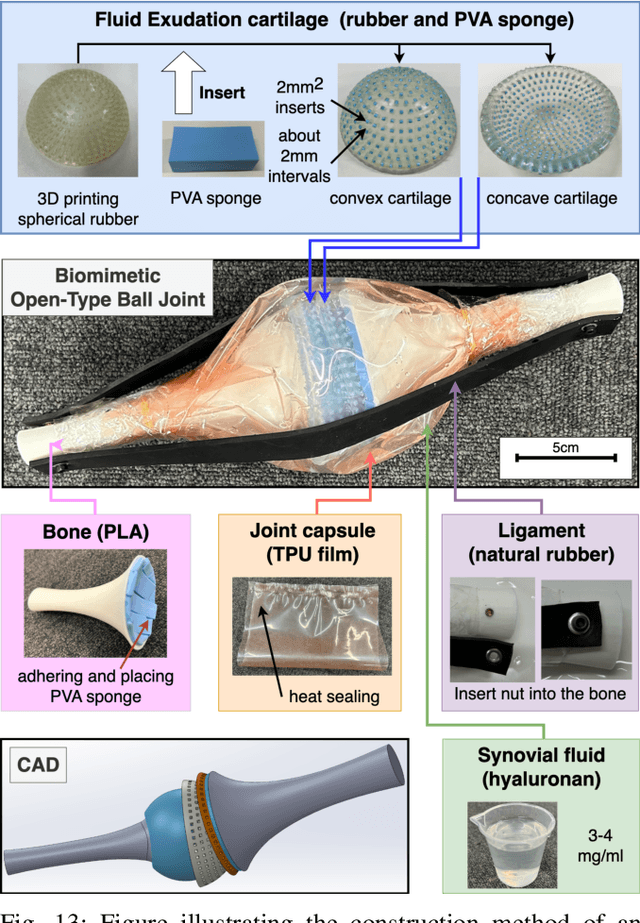

Designing Fluid-Exuding Cartilage for Biomimetic Robots Mimicking Human Joint Lubrication Function

Apr 10, 2024

Abstract:The human joint is an open-type joint composed of bones, cartilage, ligaments, synovial fluid, and joint capsule, having advantages of flexibility and impact resistance. However, replicating this structure in robots introduces friction challenges due to the absence of bearings. To address this, our study focuses on mimicking the fluid-exuding function of human cartilage. We employ a rubber-based 3D printing technique combined with absorbent materials to create a versatile and easily designed cartilage sheet for biomimetic robots. We evaluate both the fluid-exuding function and friction coefficient of the fabricated flat cartilage sheet. Furthermore, we practically create a piece of curved cartilage and an open-type biomimetic ball joint in combination with bones, ligaments, synovial fluid, and joint capsule to demonstrate the utility of the proposed cartilage sheet in the construction of such joints.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge