Shogo Makino

Task-specific Self-body Controller Acquisition by Musculoskeletal Humanoids: Application to Pedal Control in Autonomous Driving

Dec 11, 2024

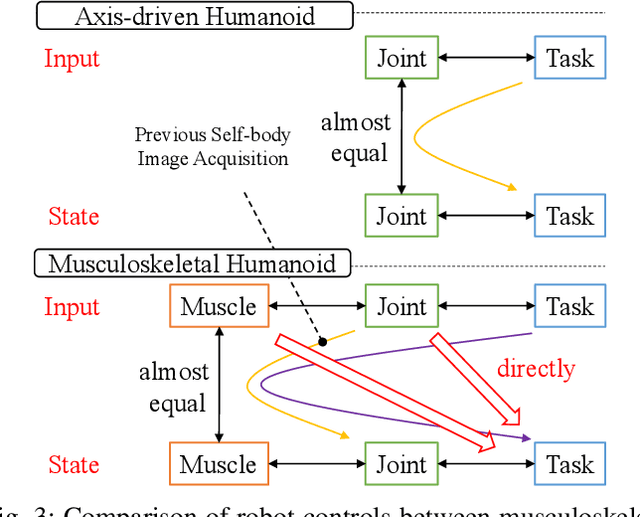

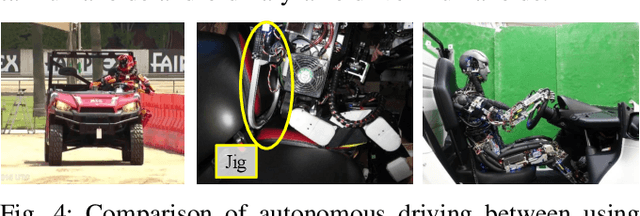

Abstract:The musculoskeletal humanoid has many benefits that human beings have, but the modeling of its complex flexible body is difficult. Although we have developed an online acquisition method of the nonlinear relationship between joints and muscles, we could not completely match the actual robot and its self-body image. When realizing a certain task, the direct relationship between the control input and task state needs to be learned. So, we construct a neural network representing the time-series relationship between the control input and task state, and realize the intended task state by applying the network to a real-time control. In this research, we conduct accelerator pedal control experiments as one application, and verify the effectiveness of this study.

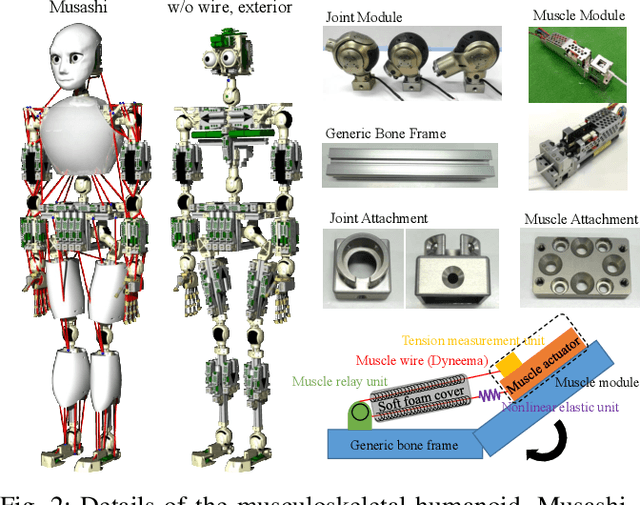

Component Modularized Design of Musculoskeletal Humanoid Platform Musashi to Investigate Learning Control Systems

Oct 29, 2024Abstract:To develop Musashi as a musculoskeletal humanoid platform to investigate learning control systems, we aimed for a body with flexible musculoskeletal structure, redundant sensors, and easily reconfigurable structure. For this purpose, we develop joint modules that can directly measure joint angles, muscle modules that can realize various muscle routes, and nonlinear elastic units with soft structures, etc. Next, we develop MusashiLarm, a musculoskeletal platform composed of only joint modules, muscle modules, generic bone frames, muscle wire units, and a few attachments. Finally, we develop Musashi, a musculoskeletal humanoid platform which extends MusashiLarm to the whole body design, and conduct several basic experiments and learning control experiments to verify the effectiveness of its concept.

Antagonist Inhibition Control in Redundant Tendon-driven Structures Based on Human Reciprocal Innervation for Wide Range Limb Motion of Musculoskeletal Humanoids

Sep 01, 2024

Abstract:The body structure of an anatomically correct tendon-driven musculoskeletal humanoid is complex, and the difference between its geometric model and the actual robot is very large because expressing the complex routes of tendon wires in a geometric model is very difficult. If we move a tendon-driven musculoskeletal humanoid by the tendon wire lengths of the geometric model, unintended muscle tension and slack will emerge. In some cases, this can lead to the wreckage of the actual robot. To solve this problem, we focused on reciprocal innervation in the human nervous system, and then implemented antagonist inhibition control (AIC) based on the reflex. This control makes it possible to avoid unnecessary internal muscle tension and slack of tendon wires caused by model error, and to perform wide range motion safely for a long time. To verify its effectiveness, we applied AIC to the upper limb of the tendon-driven musculoskeletal humanoid, Kengoro, and succeeded in dangling for 14 minutes and doing pull-ups.

Human Mimetic Forearm Design with Radioulnar Joint using Miniature Bone-Muscle Modules and Its Applications

Aug 19, 2024

Abstract:The human forearm is composed of two long, thin bones called the radius and the ulna, and rotates using two axle joints. We aimed to develop a forearm based on the body proportion, weight ratio, muscle arrangement, and joint performance of the human body in order to bring out its benefits. For this, we need to miniaturize the muscle modules. To approach this task, we arranged two muscle motors inside one muscle module, and used the space effectively by utilizing common parts. In addition, we enabled the muscle module to also be used as the bone structure. Moreover, we used miniature motors and developed a way to dissipate the motor heat to the bone structure. Through these approaches, we succeeded in developing a forearm with a radioulnar joint based on the body proportion, weight ratio, muscle arrangement, and joint performance of the human body, while keeping maintainability and reliability. Also, we performed some motions such as soldering, opening a book, turning a screw, and badminton swinging using the benefits of the radioulnar structure, which have not been discussed before, and verified that Kengoro can realize skillful motions using the radioulnar joint like a human.

A Method of Joint Angle Estimation Using Only Relative Changes in Muscle Lengths for Tendon-driven Humanoids with Complex Musculoskeletal Structures

Apr 22, 2024

Abstract:Tendon-driven musculoskeletal humanoids typically have complex structures similar to those of human beings, such as ball joints and the scapula, in which encoders cannot be installed. Therefore, joint angles cannot be directly obtained and need to be estimated using the changes in muscle lengths. In previous studies, methods using table-search and extended kalman filter have been developed. These methods express the joint-muscle mapping, which is the nonlinear relationship between joint angles and muscle lengths, by using a data table, polynomials, or a neural network. However, due to computational complexity, these methods cannot consider the effects of polyarticular muscles. In this study, considering the limitation of the computational cost, we reduce unnecessary degrees of freedom, divide joints and muscles into several groups, and formulate a joint angle estimation method that takes into account polyarticular muscles. Also, we extend the estimation method to propose a joint angle estimation method using only the relative changes in muscle lengths. By this extension, which does not use absolute muscle lengths, we do not need to execute a difficult calibration of muscle lengths for tendon-driven musculoskeletal humanoids. Finally, we conduct experiments in simulation and actual environments, and verify the effectiveness of this study.

TWIMP: Two-Wheel Inverted Musculoskeletal Pendulum as a Learning Control Platform in the Real World with Environmental Physical Contact

Apr 22, 2024

Abstract:By the recent spread of machine learning in the robotics field, a humanoid that can act, perceive, and learn in the real world through contact with the environment needs to be developed. In this study, as one of the choices, we propose a novel humanoid TWIMP, which combines a human mimetic musculoskeletal upper limb with a two-wheel inverted pendulum. By combining the benefit of a musculoskeletal humanoid, which can achieve soft contact with the external environment, and the benefit of a two-wheel inverted pendulum with a small footprint and high mobility, we can easily investigate learning control systems in environments with contact and sudden impact. We reveal our whole concept and system details of TWIMP, and execute several preliminary experiments to show its potential ability.

Online Learning of Joint-Muscle Mapping Using Vision in Tendon-driven Musculoskeletal Humanoids

Apr 08, 2024

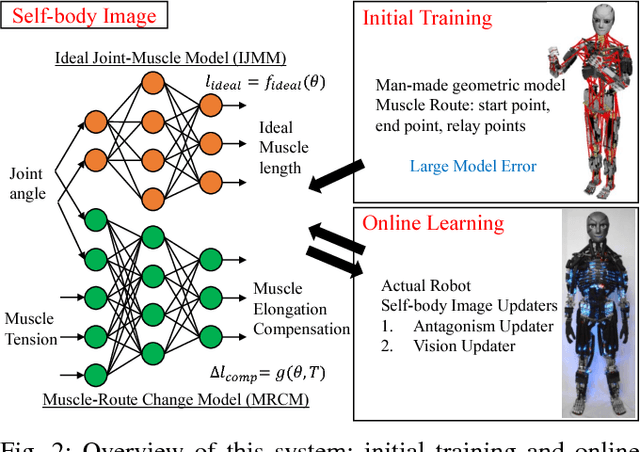

Abstract:The body structures of tendon-driven musculoskeletal humanoids are complex, and accurate modeling is difficult, because they are made by imitating the body structures of human beings. For this reason, we have not been able to move them accurately like ordinary humanoids driven by actuators in each axis, and large internal muscle tension and slack of tendon wires have emerged by the model error between its geometric model and the actual robot. Therefore, we construct a joint-muscle mapping (JMM) using a neural network (NN), which expresses a nonlinear relationship between joint angles and muscle lengths, and aim to move tendon-driven musculoskeletal humanoids accurately by updating the JMM online from data of the actual robot. In this study, the JMM is updated online by using the vision of the robot so that it moves to the correct position (Vision Updater). Also, we execute another update to modify muscle antagonisms correctly (Antagonism Updater). By using these two updaters, the error between the target and actual joint angles decrease to about 40% in 5 minutes, and we show through a manipulation experiment that the tendon-driven musculoskeletal humanoid Kengoro becomes able to move as intended. This novel system can adapt to the state change and growth of robots, because it updates the JMM online successively.

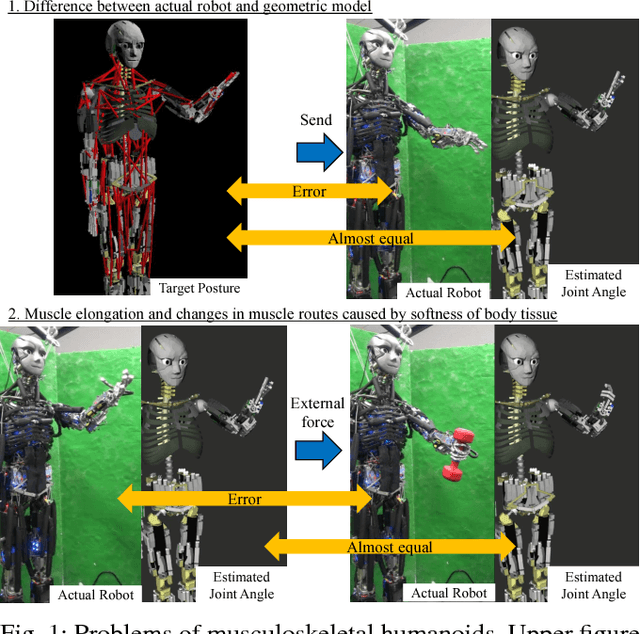

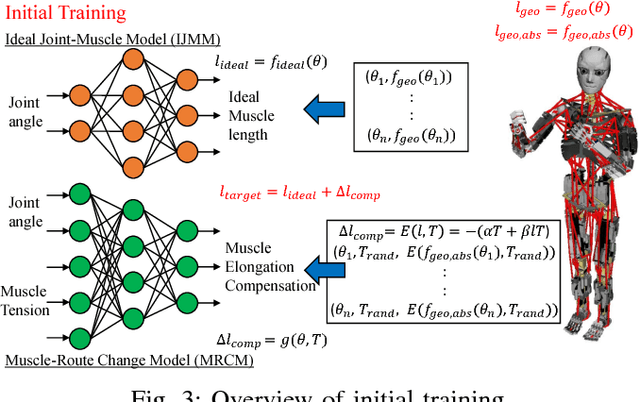

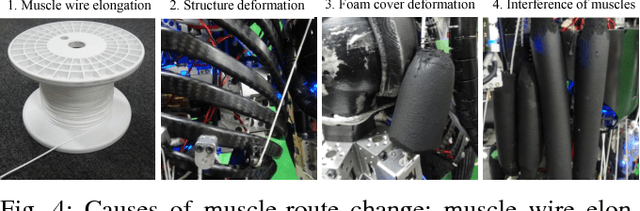

Online Self-body Image Acquisition Considering Changes in Muscle Routes Caused by Softness of Body Tissue for Tendon-driven Musculoskeletal Humanoids

Apr 08, 2024

Abstract:Tendon-driven musculoskeletal humanoids have many benefits in terms of the flexible spine, multiple degrees of freedom, and variable stiffness. At the same time, because of its body complexity, there are problems in controllability. First, due to the large difference between the actual robot and its geometric model, it cannot move as intended and large internal muscle tension may emerge. Second, movements which do not appear as changes in muscle lengths may emerge, because of the muscle route changes caused by softness of body tissue. To solve these problems, we construct two models: ideal joint-muscle model and muscle-route change model, using a neural network. We initialize these models by a man-made geometric model and update them online using the sensor information of the actual robot. We validate that the tendon-driven musculoskeletal humanoid Kengoro is able to obtain a correct self-body image through several experiments.

Long-time Self-body Image Acquisition and its Application to the Control of Musculoskeletal Structures

Apr 08, 2024

Abstract:The tendon-driven musculoskeletal humanoid has many benefits that human beings have, but the modeling of its complex muscle and bone structures is difficult and conventional model-based controls cannot realize intended movements. Therefore, a learning control mechanism that acquires nonlinear relationships between joint angles, muscle tensions, and muscle lengths from the actual robot is necessary. In this study, we propose a system which runs the learning control mechanism for a long time to keep the self-body image of the musculoskeletal humanoid correct at all times. Also, we show that the musculoskeletal humanoid can conduct position control, torque control, and variable stiffness control using this self-body image. We conduct a long-time self-body image acquisition experiment lasting 3 hours, evaluate variable stiffness control using the self-body image, etc., and discuss the superiority and practicality of the self-body image acquisition of musculoskeletal structures, comprehensively.

High-Power, Flexible, Robust Hand: Development of Musculoskeletal Hand Using Machined Springs and Realization of Self-Weight Supporting Motion with Humanoid

Mar 26, 2024Abstract:Human can not only support their body during standing or walking, but also support them by hand, so that they can dangle a bar and others. But most humanoid robots support their body only in the foot and they use their hand just to manipulate objects because their hands are too weak to support their body. Strong hands are supposed to enable humanoid robots to act in much broader scene. Therefore, we developed new life-size five-fingered hand that can support the body of life-size humanoid robot. It is tendon-driven and underactuated hand and actuators in forearms produce large gripping force. This hand has flexible joints using machined springs, which can be designed integrally with the attachment. Thus, it has both structural strength and impact resistance in spite of small size. As other characteristics, this hand has force sensors to measure external force and the fingers can be flexed along objects though the number of actuators to flex fingers is less than that of fingers. We installed the developed hand on musculoskeletal humanoid "Kengoro" and achieved two self-weight supporting motions: push-up motion and dangling motion.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge