Huixu Dong

Construction of a Multiple-DOF Under-actuated Gripper with Force-Sensing via Deep Learning

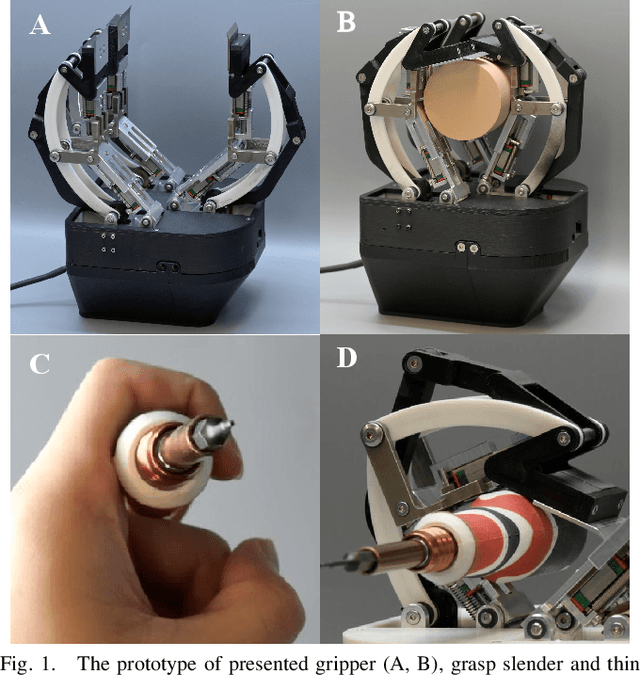

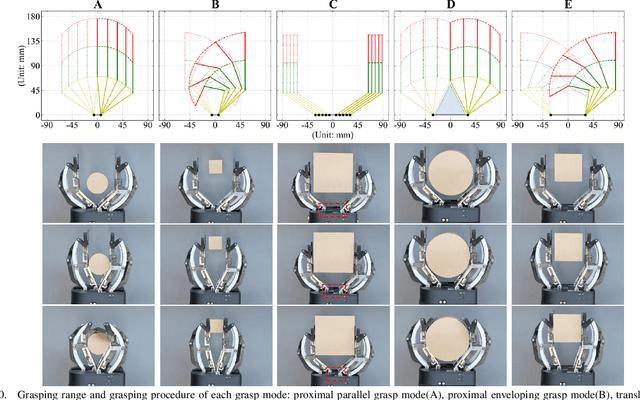

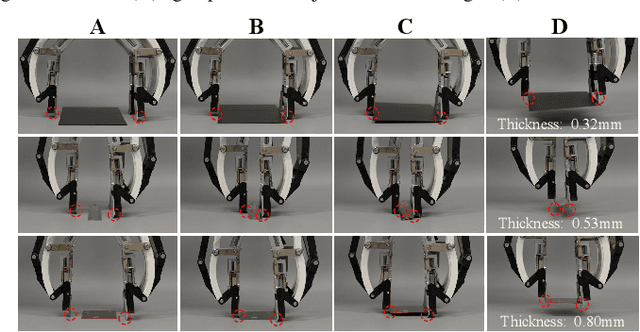

Jun 13, 2025Abstract:We present a novel under-actuated gripper with two 3-joint fingers, which realizes force feedback control by the deep learning technique- Long Short-Term Memory (LSTM) model, without any force sensor. First, a five-linkage mechanism stacked by double four-linkages is designed as a finger to automatically achieve the transformation between parallel and enveloping grasping modes. This enables the creation of a low-cost under-actuated gripper comprising a single actuator and two 3-phalange fingers. Second, we devise theoretical models of kinematics and power transmission based on the proposed gripper, accurately obtaining fingertip positions and contact forces. Through coupling and decoupling of five-linkage mechanisms, the proposed gripper offers the expected capabilities of grasping payload/force/stability and objects with large dimension ranges. Third, to realize the force control, an LSTM model is proposed to determine the grasping mode for synthesizing force-feedback control policies that exploit contact sensing after outlining the uncertainty of currents using a statistical method. Finally, a series of experiments are implemented to measure quantitative indicators, such as the payload, grasping force, force sensing, grasping stability and the dimension ranges of objects to be grasped. Additionally, the grasping performance of the proposed gripper is verified experimentally to guarantee the high versatility and robustness of the proposed gripper.

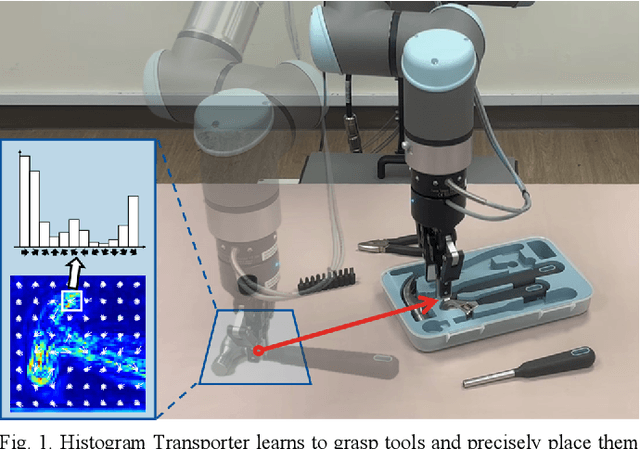

Histogram Transporter: Learning Rotation-Equivariant Orientation Histograms for High-Precision Robotic Kitting

Mar 16, 2025

Abstract:Robotic kitting is a critical task in industrial automation that requires the precise arrangement of objects into kits to support downstream production processes. However, when handling complex kitting tasks that involve fine-grained orientation alignment, existing approaches often suffer from limited accuracy and computational efficiency. To address these challenges, we propose Histogram Transporter, a novel kitting framework that learns high-precision pick-and-place actions from scratch using only a few demonstrations. First, our method extracts rotation-equivariant orientation histograms (EOHs) from visual observations using an efficient Fourier-based discretization strategy. These EOHs serve a dual purpose: improving picking efficiency by directly modeling action success probabilities over high-resolution orientations and enhancing placing accuracy by serving as local, discriminative feature descriptors for object-to-placement matching. Second, we introduce a subgroup alignment strategy in the place model that compresses the full spectrum of EOHs into a compact orientation representation, enabling efficient feature matching while preserving accuracy. Finally, we examine the proposed framework on the simulated Hand-Tool Kitting Dataset (HTKD), where it outperforms competitive baselines in both success rates and computational efficiency. Further experiments on five Raven-10 tasks exhibits the remarkable adaptability of our approach, with real-robot trials confirming its applicability for real-world deployment.

GelSight FlexiRay: Breaking Planar Limits by Harnessing Large Deformations for Flexible,Full-Coverage Multimodal Sensing

Nov 28, 2024

Abstract:The integration of tactile sensing into compliant soft robotic grippers offers a compelling pathway toward advanced robotic grasping and safer human-robot interactions. Visual-tactile sensors realize high-resolution, large-area tactile perception with affordable cameras. However, conventional visual-tactile sensors rely heavily on rigid forms, sacrificing finger compliance and sensing regions to achieve localized tactile feedback. Enabling seamless, large-area tactile sensing in soft grippers remains challenging, as deformations inherent to soft structures can obstruct the optical path and restrict the camera's field of view. To address these, we present Gelsight FlexiRay, a multimodal visual-tactile sensor designed for safe and compliant interactions with substantial structural deformation through integration with Finray Effect grippers. First, we adopt a multi-mirror configuration, which is systematically modeled and optimized based on the physical force-deformation characteristics of FRE grippers. Second, we enhanced Gelsight FlexiRay with human-like multimodal perception, including contact force and location, proprioception, temperature, texture, and slippage. Experiments demonstrate Gelsight FlexiRay's robust tactile performance across diverse deformation states, achieving a force measurement accuracy of 0.14 N and proprioceptive positioning accuracy of 0.19 mm. Compared with state of art compliant VTS, the FlexiRay demonstrates 5 times larger structural deformation under the same loads. Its expanded sensing area and ability to distinguish contact information and execute grasping and classification tasks highlights its potential for versatile, large-area multimodal tactile sensing integration within soft robotic systems. This work establishes a foundation for flexible, high-resolution tactile sensing in compliant robotic applications.

Discretizing SO(2)-Equivariant Features for Robotic Kitting

Mar 20, 2024Abstract:Robotic kitting has attracted considerable attention in logistics and industrial settings. However, existing kitting methods encounter challenges such as low precision and poor efficiency, limiting their widespread applications. To address these issues, we present a novel kitting framework that improves both the precision and computational efficiency of complex kitting tasks. Firstly, our approach introduces a fine-grained orientation estimation technique in the picking module, significantly enhancing orientation precision while effectively decoupling computational load from orientation granularity. This approach combines an SO(2)-equivariant network with a group discretization operation to preciously predict discrete orientation distributions. Secondly, we develop the Hand-tool Kitting Dataset (HKD) to evaluate the performance of different solutions in handling orientation-sensitive kitting tasks. This dataset comprises a diverse collection of hand tools and synthetically created kits, which reflects the complexities encountered in real-world kitting scenarios. Finally, a series of experiments are conducted to evaluate the performance of the proposed method. The results demonstrate that our approach offers remarkable precision and enhanced computational efficiency in robotic kitting tasks.

Bin Packing Optimization via Deep Reinforcement Learning

Mar 19, 2024Abstract:The Bin Packing Problem (BPP) has attracted enthusiastic research interest recently, owing to widespread applications in logistics and warehousing environments. It is truly essential to optimize the bin packing to enable more objects to be packed into boxes. Object packing order and placement strategy are the two crucial optimization objectives of the BPP. However, existing optimization methods for BPP, such as the genetic algorithm (GA), emerge as the main issues in highly computational cost and relatively low accuracy, making it difficult to implement in realistic scenarios. To well relieve the research gaps, we present a novel optimization methodology of two-dimensional (2D)-BPP and three-dimensional (3D)-BPP for objects with regular shapes via deep reinforcement learning (DRL), maximizing the space utilization and minimizing the usage number of boxes. First, an end-to-end DRL neural network constructed by a modified Pointer Network consisting of an encoder, a decoder and an attention module is proposed to achieve the optimal object packing order. Second, conforming to the top-down operation mode, the placement strategy based on a height map is used to arrange the ordered objects in the boxes, preventing the objects from colliding with boxes and other objects in boxes. Third, the reward and loss functions are defined as the indicators of the compactness, pyramid, and usage number of boxes to conduct the training of the DRL neural network based on an on-policy actor-critic framework. Finally, a series of experiments are implemented to compare our method with conventional packing methods, from which we conclude that our method outperforms these packing methods in both packing accuracy and efficiency.

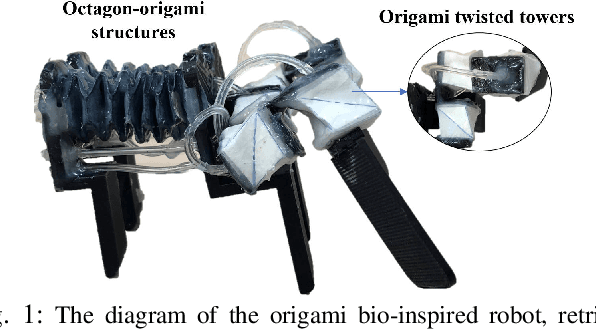

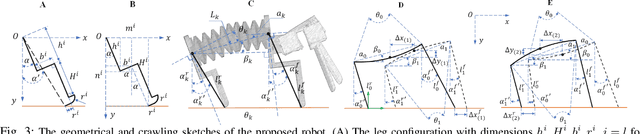

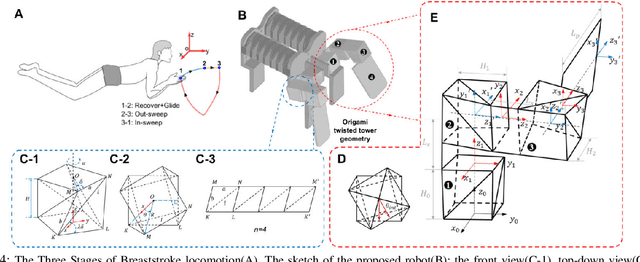

Theoretical Modeling and Bio-inspired Trajectory Optimization of A Multiple-locomotion Origami Robot

Mar 19, 2024

Abstract:Recent research on mobile robots has focused on increasing their adaptability to unpredictable and unstructured environments using soft materials and structures. However, the determination of key design parameters and control over these compliant robots are predominantly iterated through experiments, lacking a solid theoretical foundation. To improve their efficiency, this paper aims to provide mathematics modeling over two locomotion, crawling and swimming. Specifically, a dynamic model is first devised to reveal the influence of the contact surfaces' frictional coefficients on displacements in different motion phases. Besides, a swimming kinematics model is provided using coordinate transformation, based on which, we further develop an algorithm that systematically plans human-like swimming gaits, with maximum thrust obtained. The proposed algorithm is highly generalizable and has the potential to be applied in other soft robots with multiple joints. Simulation experiments have been conducted to illustrate the effectiveness of the proposed modeling.

Under-actuated Robotic Gripper with Multiple Grasping Modes Inspired by Human Finger

Mar 19, 2024

Abstract:Under-actuated robot grippers as a pervasive tool of robots have become a considerable research focus. Despite their simplicity of mechanical design and control strategy, they suffer from poor versatility and weak adaptability, making widespread applications limited. To better relieve relevant research gaps, we present a novel 3-finger linkage-based gripper that realizes retractable and reconfigurable multi-mode grasps driven by a single motor. Firstly, inspired by the changes that occurred in the contact surface with a human finger moving, we artfully design a slider-slide rail mechanism as the phalanx to achieve retraction of each finger, allowing for better performance in the enveloping grasping mode. Secondly, a reconfigurable structure is constructed to broaden the grasping range of objects' dimensions for the proposed gripper. By adjusting the configuration and gesture of each finger, the gripper can achieve five grasping modes. Thirdly, the proposed gripper is just actuated by a single motor, yet it can be capable of grasping and reconfiguring simultaneously. Finally, various experiments on grasps of slender, thin, and large-volume objects are implemented to evaluate the performance of the proposed gripper in practical scenarios, which demonstrates the excellent grasping capabilities of the gripper.

Unveiling the Complete Variant of Spherical Robots

Mar 06, 2024

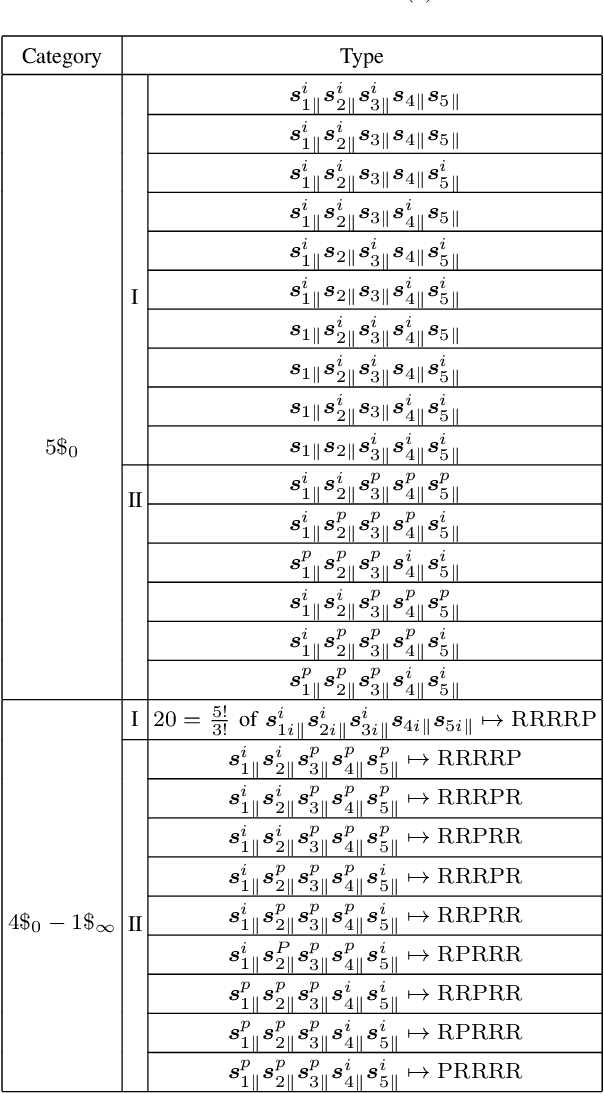

Abstract:This study presents a systematic enumeration of spherical ($SO(3)$) type parallel robots' variants using an analytical velocity-level approach. These robots are known for their ability to perform arbitrary rotations around a fixed point, making them suitable for numerous applications. Despite their architectural diversity, existing research has predominantly approached them on a case-by-case basis. This approach hinders the exploration of all possible variants, thereby limiting the benefits derived from architectural diversity. By employing a generalized analytical approach through the reciprocal screw method, we systematically explore all the kinematic conditions for limbs yielding $SO(3)$ motion.Consequently, all 73 possible types of non-redundant limbs suitable for generating the target $SO(3)$ motion are identified. The approach involves performing an in-depth algebraic motion-constraint analysis and identifying common characteristics among different variants. This leads us to systematically explore all 73 symmetric and 5256 asymmetric variants, which in turn become a total of 5329, each potentially having different workspace capability, stiffness performance, and dynamics. Hence, having all these variants can facilitate the innovation of novel spherical robots and help us easily find the best and optimal ones for our specific applications.

Theoretical Model Construction of Deformation-Force for Soft Grippers Part I: Co-rotational Modeling and Force Control for Design Optimization

Mar 23, 2023

Abstract:Compliant grippers, owing to adaptivity and safety, have attracted considerable attention for unstructured grasping in real applications, such as industrial or logistic scenarios. However, accurate construction of the mathematical model depicting the bidirectional relationship between shape deformation and contact force for such grippers, such as the Fin-Ray grippers, remains stagnant to date. To address this research gap, this article devises, presents, and experimentally validates a universal bidirectional force-displacement mathematical model for compliant grippers based on the co-rotational concept, which endows such grippers with an intrinsic force sensing capability and offers a better insight into the design optimization. In Part 1 of the article, we introduce the fundamental theory of the co-rotational approach, where arbitrary large deformation of beam elements can be modeled. Its intrinsic principle enables the theoretical modeling to consider various types of configurations and key design parameters with very few assumptions made. Further, a force control algorithm is proposed, providing accurate displacement estimations of the gripper under external forces with minor computational loads. The performance of the proposed method is experimentally verified through comparison with Finite Element Analysis, where the influence of four key design parameters on the gripper s performance is investigated, facilitating systematical design optimization. Part 2 of this article demonstrating the force sensing capabilities and the effects of representative co-rotational modeling parameters on model accuracy is released in Google Drive.

Theoretical Model Construction of Deformation-Force for Soft Grippers Part II: Displacement Control Based Intrinsic Force Sensing

Mar 22, 2023

Abstract:Compliant grasping is an essential capability for most robots in practical applications. For compliant robotic end-effectors that commonly appear in industrial or logistic scenarios, such as Fin-Ray gripper, it still remains challenging to build a bidirectional mathematical model that mutually maps the shape deformation and contact force. Part I of this article has constructed the force-displacement relationship for design optimization through the co-rotational theory with very few assumptions. In Part II, we further devise a detailed displacement-force mathematical model, enabling the compliant gripper to precisely estimate contact force sensor-free. Specifically, the proposed approach based on the co-rotational theory can calculate contact forces from deformations. The presented displacement-control algorithm elaborately investigates contact forces and provides force feedback for a force control system of a gripper, where deformation appears as displacements in contact points. Afterward, simulation experiments are conducted to evaluate the performance of the proposed model through comparisons with the finite-element analysis (FEA). Simulation results reveal that the proposed model accurately estimates contact force, with an average error of around 5% throughout all single/multiple node cases, regardless of various design parameters (Part I of this article is released in Google Drive).

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge