Fabio Stroppa

Design Optimizer for Soft Growing Robot Manipulators in Three-Dimensional Environments

Dec 31, 2024

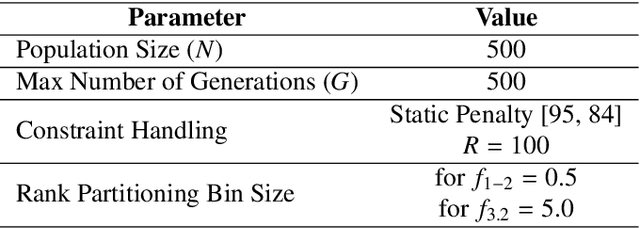

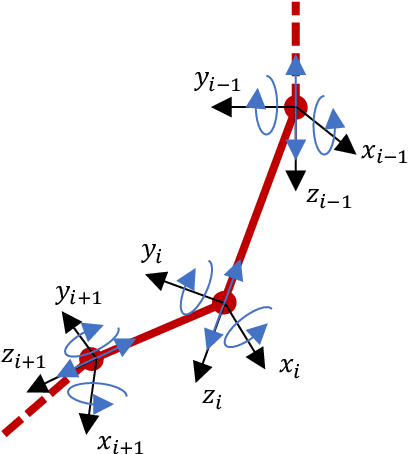

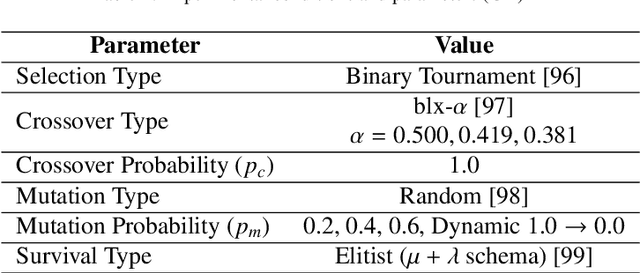

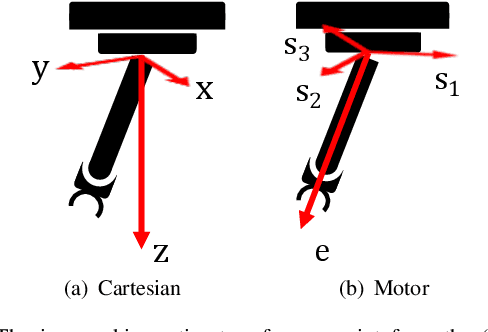

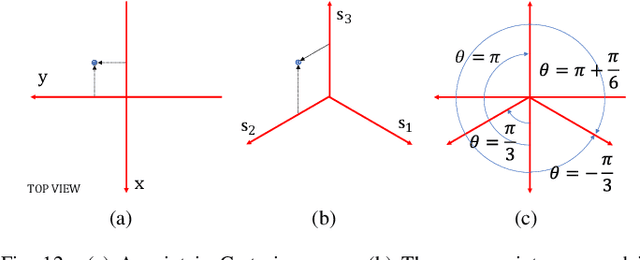

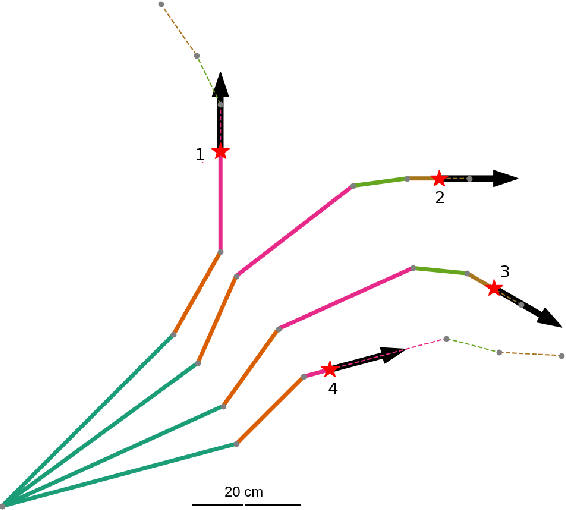

Abstract:Soft growing robots are novel devices that mimic plant-like growth for navigation in cluttered or dangerous environments. Their ability to adapt to surroundings, combined with advancements in actuation and manufacturing technologies, allows them to perform specialized manipulation tasks. This work presents an approach for design optimization of soft growing robots; specifically, the three-dimensional extension of the optimizer designed for planar manipulators. This tool is intended to be used by engineers and robot enthusiasts before manufacturing their robot: it suggests the optimal size of the robot for solving a specific task. The design process models a multi-objective optimization problem to refine a soft manipulator's kinematic chain. Thanks to the novel Rank Partitioning algorithm integrated into Evolutionary Computation (EC) algorithms, this method achieves high precision in reaching targets and is efficient in resource usage. Results show significantly high performance in solving three-dimensional tasks, whereas comparative experiments indicate that the optimizer features robust output when tested with different EC algorithms, particularly genetic algorithms.

Enhanced Optimization Strategies to Design an Underactuated Hand Exoskeleton

Aug 14, 2024Abstract:Exoskeletons can boost human strength and provide assistance to individuals with physical disabilities. However, ensuring safety and optimal performance in their design poses substantial challenges. This study presents the design process for an underactuated hand exoskeleton (U-HEx), first including a single objective (maximizing force transmission), then expanding into multi objective (also minimizing torque variance and actuator displacement). The optimization relies on a Genetic Algorithm, the Big Bang-Big Crunch Algorithm, and their versions for multi-objective optimization. Analyses revealed that using Big Bang-Big Crunch provides high and more consistent results in terms of optimality with lower convergence time. In addition, adding more objectives offers a variety of trade-off solutions to the designers, who might later set priorities for the objectives without repeating the process - at the cost of complicating the optimization algorithm and computational burden. These findings underline the importance of performing proper optimization while designing exoskeletons, as well as providing a significant improvement to this specific robotic design.

The Impact of Evolutionary Computation on Robotic Design: A Case Study with an Underactuated Hand Exoskeleton

Mar 23, 2024Abstract:Robotic exoskeletons can enhance human strength and aid people with physical disabilities. However, designing them to ensure safety and optimal performance presents significant challenges. Developing exoskeletons should incorporate specific optimization algorithms to find the best design. This study investigates the potential of Evolutionary Computation (EC) methods in robotic design optimization, with an underactuated hand exoskeleton (U-HEx) used as a case study. We propose improving the performance and usability of the U-HEx design, which was initially optimized using a naive brute-force approach, by integrating EC techniques such as Genetic Algorithm and Big Bang-Big Crunch Algorithm. Comparative analysis revealed that EC methods consistently yield more precise and optimal solutions than brute force in a significantly shorter time. This allowed us to improve the optimization by increasing the number of variables in the design, which was impossible with naive methods. The results show significant improvements in terms of the torque magnitude the device transfers to the user, enhancing its efficiency. These findings underline the importance of performing proper optimization while designing exoskeletons, as well as providing a significant improvement to this specific robotic design.

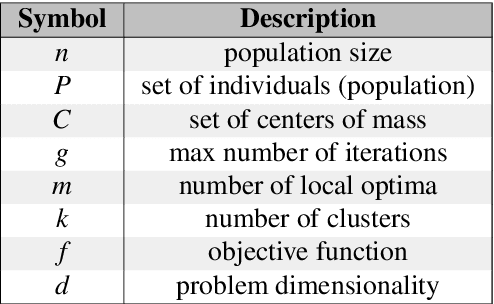

Multi-Modal Optimization with k-Cluster Big Bang-Big Crunch Algorithm

Dec 21, 2023

Abstract:Multi-modal optimization is often encountered in engineering problems, especially when different and alternative solutions are sought. Evolutionary algorithms can efficiently tackle multi-modal optimization thanks to their features such as the concept of population, exploration/exploitation, and being suitable for parallel computation. This paper introduces a multi-modal optimization version of the Big Bang-Big Crunch algorithm based on clustering, namely, k-BBBC. This algorithm guarantees a complete convergence of the entire population, retrieving on average the 99\% of local optima for a specific problem. Additionally, we introduce two post-processing methods to (i) identify the local optima in a set of retrieved solutions (i.e., a population), and (ii) quantify the number of correctly retrieved optima against the expected ones (i.e., success rate). Our results show that k-BBBC performs well even with problems having a large number of optima (tested on 379 optima) and high dimensionality (tested on 32 decision variables). When compared to other multi-modal optimization methods, it outperforms them in terms of accuracy (in both search and objective space) and success rate (number of correctly retrieved optima) -- especially when elitism is applied. Lastly, we validated our proposed post-processing methods by comparing their success rate to the actual one. Results suggest that these methods can be used to evaluate the performance of a multi-modal optimization algorithm by correctly identifying optima and providing an indication of success -- without the need to know where the optima are located in the search space.

Design Optimizer for Planar Soft-Growing Robot Manipulators

Oct 05, 2023Abstract:Soft-growing robots are innovative devices that feature plant-inspired growth to navigate environments. Thanks to their embodied intelligence of adapting to their surroundings and the latest innovation in actuation and manufacturing, it is possible to employ them for specific manipulation tasks. The applications of these devices include exploration of delicate/dangerous environments, manipulation of items, or assistance in domestic environments. This work presents a novel approach for design optimization of soft-growing robots, which will be used prior to manufacturing to suggest engineers -- or robot designer enthusiasts -- the optimal dimension of the robot to be built for solving a specific task. I modeled the design process as a multi-objective optimization problem, in which I optimize the kinematic chain of a soft manipulator to reach targets and avoid unnecessary overuse of material and resources. The method exploits the advantages of population-based optimization algorithms, in particular evolutionary algorithms, to transform the problem from multi-objective into a single-objective thanks to an efficient mathematical formulation, the novel rank-partitioning algorithm, and obstacle avoidance integrated within the optimizer operators. I tested the proposed method on different tasks to access its optimality, which showed significant performance in solving the problem. Finally, comparative experiments showed that the proposed method works better than the one existing in the literature in terms of precision, resource consumption, and run time.

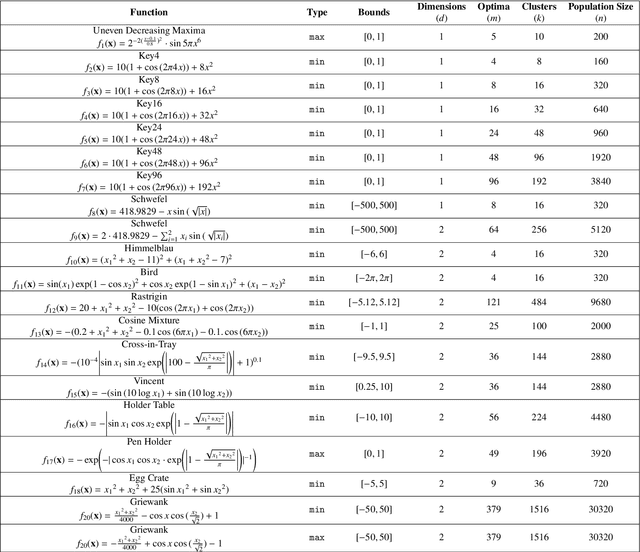

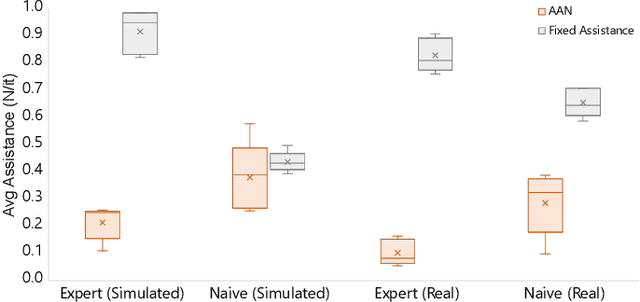

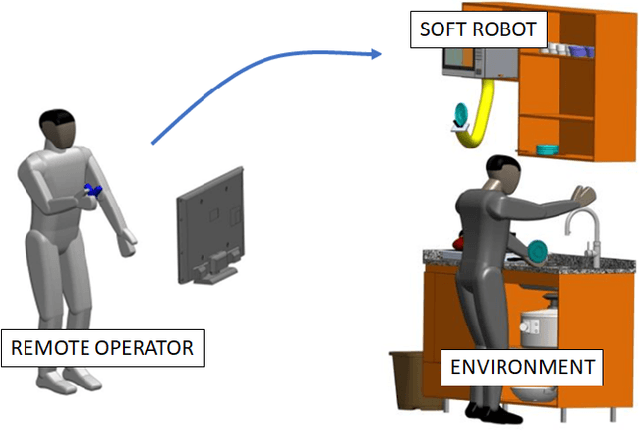

Shared-Control Teleoperation Paradigms on a Soft Growing Robot Manipulator

Aug 02, 2021

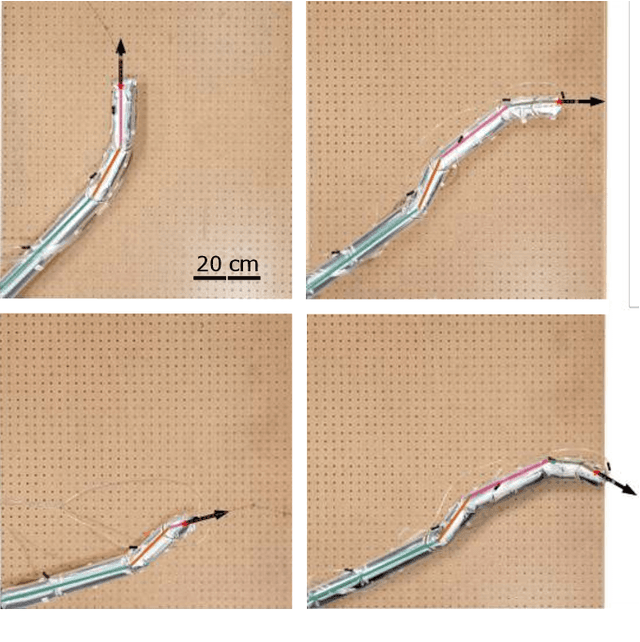

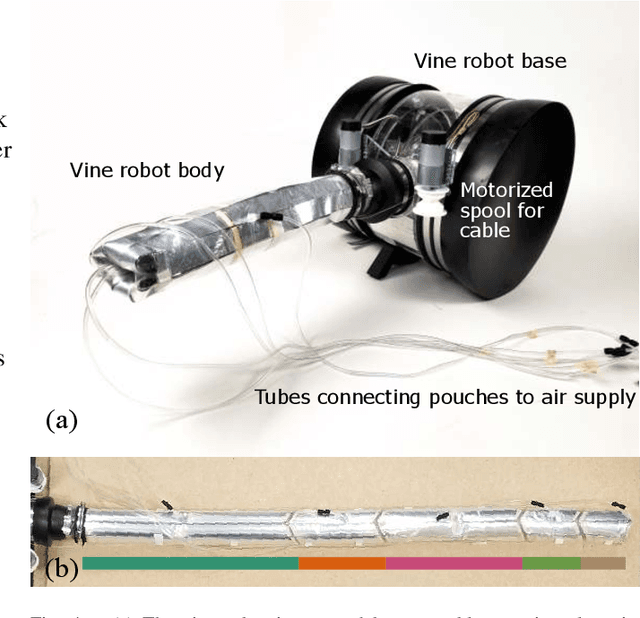

Abstract:Semi-autonomous telerobotic systems allow both humans and robots to exploit their strengths, while enabling personalized execution of a task. However, for new soft robots with degrees of freedom dissimilar to those of human operators, it is unknown how the control of a task should be divided between the human and robot. This work presents a set of interaction paradigms between a human and a soft growing robot manipulator, and demonstrates them in both real and simulated scenarios. The robot can grow and retract by eversion and inversion of its tubular body, a property we exploit to implement interaction paradigms. We implemented and tested six different paradigms of human-robot interaction, beginning with full teleoperation and gradually adding automation to various aspects of the task execution. All paradigms were demonstrated by two expert and two naive operators. Results show that humans and the soft robot manipulator can split control along degrees of freedom while acting simultaneously. In the simple pick-and-place task studied in this work, performance improves as the control is gradually given to the robot, because the robot can correct certain human errors. However, human engagement and enjoyment may be maximized when the task is at least partially shared. Finally, when the human operator is assisted by haptic feedback based on soft robot position errors, we observed that the improvement in performance is highly dependent on the expertise of the human operator.

Task-Specific Design Optimization and Fabrication for Inflated-Beam Soft Robots with Growable Discrete Joints

Mar 08, 2021

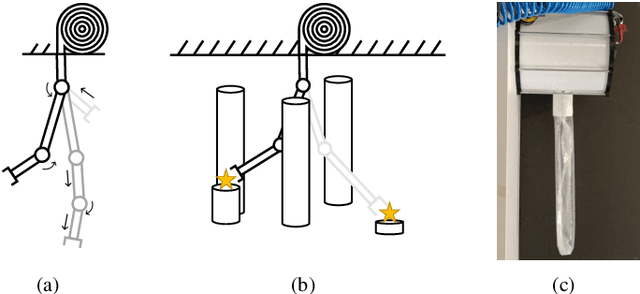

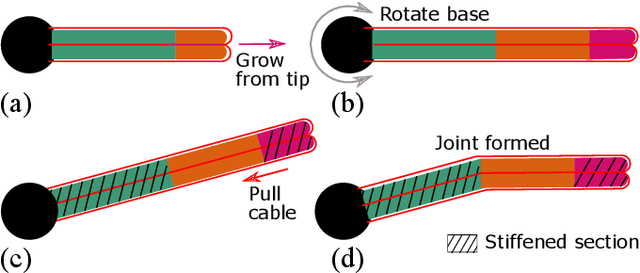

Abstract:Soft robot serial chain manipulators with the capability for growth, stiffness control, and discrete joints have the potential to approach the dexterity of traditional robot arms, while improving safety, lowering cost, and providing an increased workspace, with potential application in home environments. This paper presents an approach for design optimization of such robots to reach specified targets while minimizing the number of discrete joints and thus construction and actuation costs. We define a maximum number of allowable joints, as well as hardware constraints imposed by the materials and actuation available for soft growing robots, and we formulate and solve an optimization problem to output a robot design, i.e., the total number of potential joints and their locations along the robot body, which reaches all the desired targets. We then rapidly construct the resulting soft growing robot design using readily available, low-cost materials, and we demonstrate its ability to reach the desired targets. Finally, we use our algorithm to evaluate the ability of this design to reach new targets, and we demonstrate the algorithm's utility as a design tool to explore robot capabilities given various constraints and objectives.

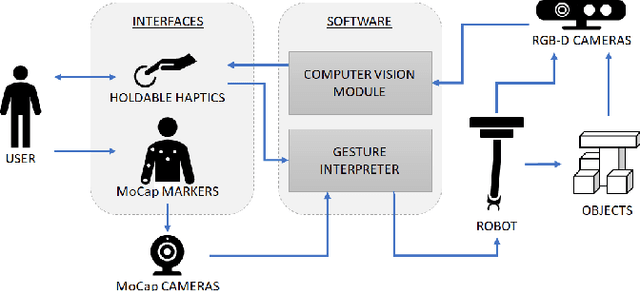

Human-centered Control of a Growing Soft Robot for Object Manipulation

Oct 28, 2019

Abstract:We present a user-friendly interface to teleoperate a soft robot manipulator in a complex environment. Key components of the system include a manipulator with a grasping end-effector that grows via tip eversion, gesture-based control, and haptic display to the operator for feedback and guidance. In the initial work, the operator uses the soft robot to build a tower of blocks, and future works will extend this to shared autonomy scenarios in which the human operator and robot intelligence are both necessary for task completion.

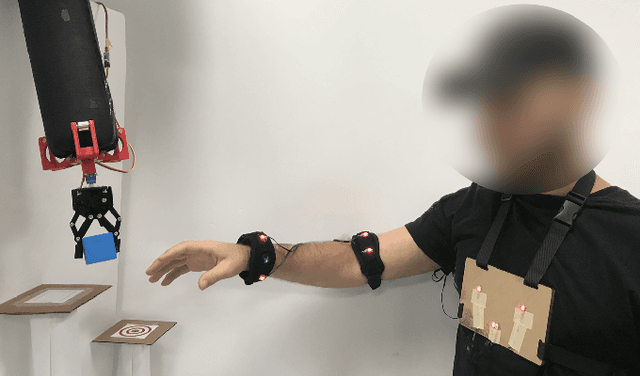

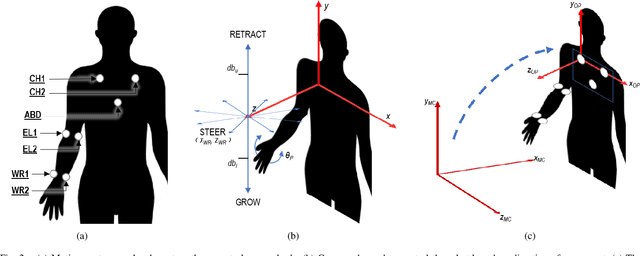

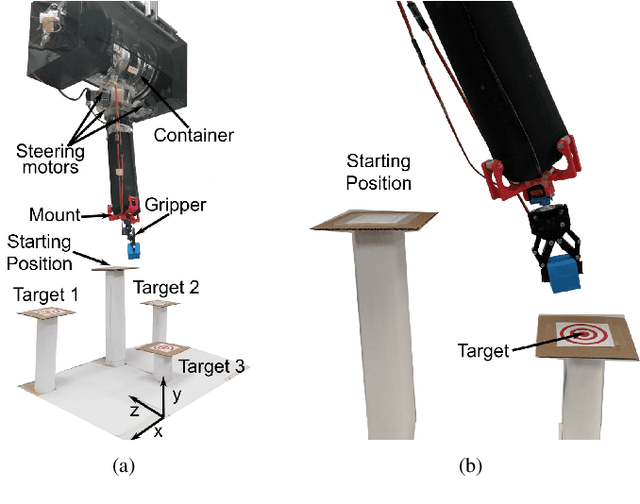

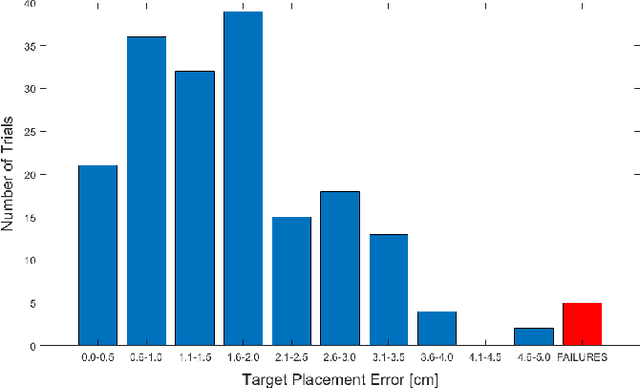

Human Interface for Teleoperated Object Manipulation with a Soft Growing Robot

Oct 28, 2019

Abstract:Soft growing robots are proposed for use in applications such as complex manipulation tasks or navigation in disaster scenarios. Safe interaction and ease of production promote the usage of this technology, but soft robots can be challenging to teleoperate due to their unique degrees of freedom. In this paper, we propose a human-centered interface that allows users to teleoperate a soft growing robot for manipulation tasks using arm movements. A study was conducted to assess the intuitiveness of the interface and the performance of our soft robot, involving a pick-and-place manipulation task. The results show that users completed the task with a success rate of 97%, achieving placement errors below 2 cm on average. These results demonstrate that our body-movement-based interface is an effective method for control of a soft growing robot manipulator.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge