Nathaniel Agharese

Configuration and Fabrication of Preformed Vine Robots

Jun 01, 2023

Abstract:Vine robots are a class of soft continuum robots that grow via tip eversion, allowing them to move their tip without relying on reaction forces from the environment. Constructed from compliant materials such as fabric and thin, flexible plastic, these robots are able to grow many times their original length with the use of fluidic pressure. They can be mechanically programmed/preformed to follow a desired path during growth by changing the structure of their body prior to deployment. We present a model for fabricating preformed vine robots with discrete bends. We apply this model across combinations of three fabrication methods and two materials. One fabrication method, taping folds into the robot body, is from the literature. The other two methods, welding folds and connecting fasteners embedded in the robot body, are novel. Measurements show the ability of the resulting vine robots to follow a desired path and show that fabrication method has a significant impact. Results include bend angles with as little as 0.12 degrees of error, and segment lengths with as low as 0.36 mm of error. The required growth pressure and average growth speed of these preformed vine robots ranged from 11.5 to 23.7kPA and 3.75 to 10 cm/s, respectively. These results validate the use of preformed vine robots for deployment along known paths, and serve as a guide for choosing a fabrication method and material combination based on the specific needs of the task.

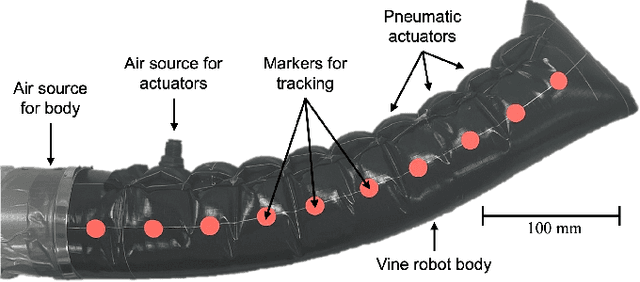

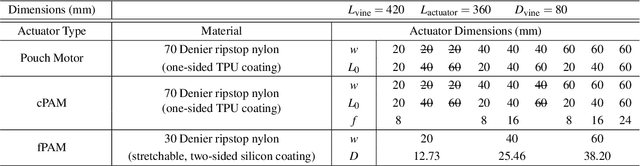

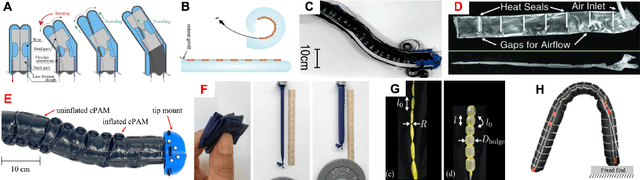

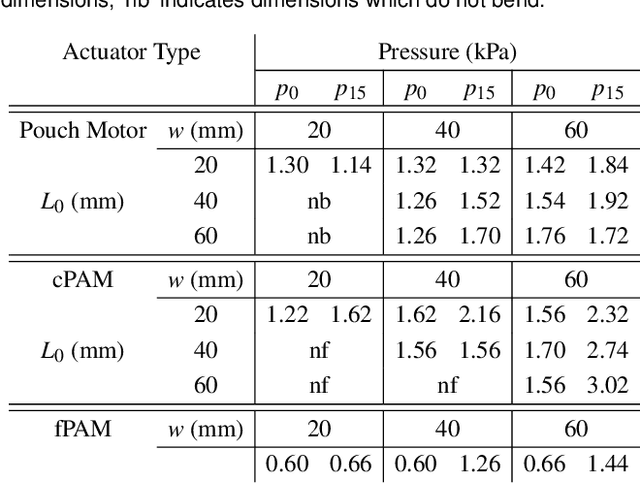

A Comparison of Pneumatic Actuators for Soft Growing Vine Robots

May 01, 2023

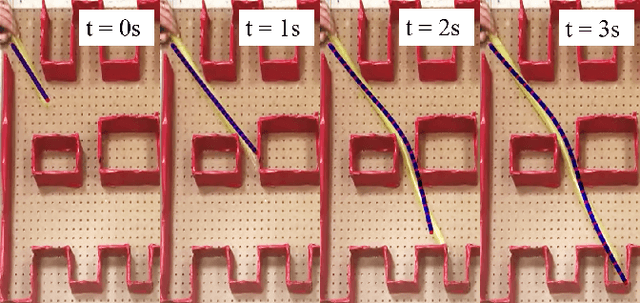

Abstract:Soft pneumatic actuators are used to steer soft growing "vine" robots while being flexible enough to undergo the tip eversion required for growth. They also meet the requirements to steer soft growing vine robots through challenging terrain. In this study, we compared the performance of three types of pneumatic actuators in terms of their ability to perform eversion, bending, dynamic motion, and force: the pouch motor, the cylindrical pneumatic artificial muscle (cPAM), and the fabric pneumatic artificial muscle (fPAM). The pouch motor is advantageous for prototyping due to its simple manufacturing process. The cPAM exhibits superior bending behavior and produces the highest forces, while the fPAM actuates fastest and everts at the lowest pressure. We evaluated a similar range of dimensions for each actuator type. Larger actuators can produce more significant deformations and forces, but smaller actuators inflate more quickly and require a lower eversion pressure. Since vine robots are lightweight, the effect of gravity on the functionality of different actuators is minimal. We developed a new analytical model that predicts the pressure-to-bending behavior of vine robot actuators. Using the actuator results, we designed and demonstrated a 4.8 m long vine robot equipped with highly maneuverable 60x60 mm cPAMs in a three-dimensional obstacle course. The vine robot was able to move around sharp turns, travel through a passage smaller than its diameter, and lift itself against gravity.

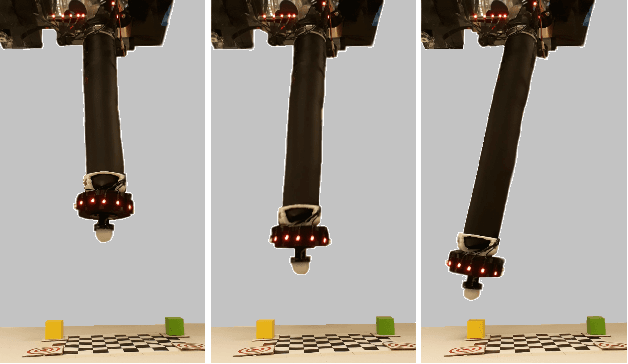

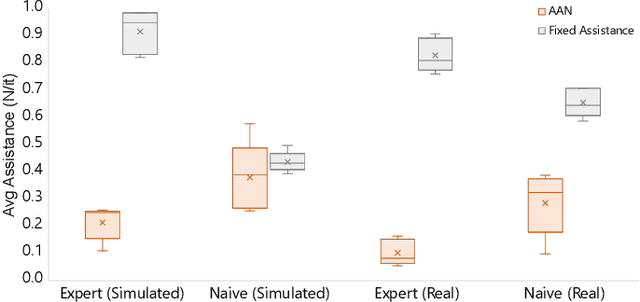

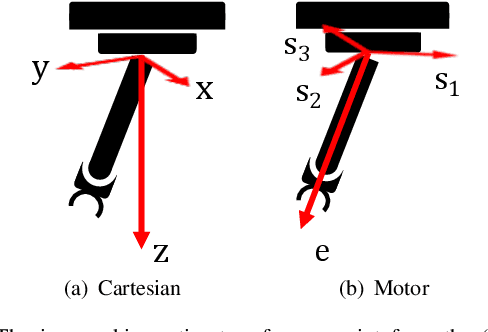

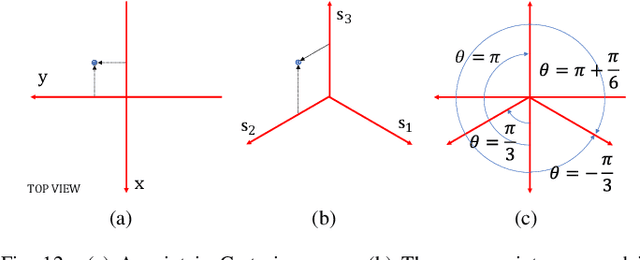

Shared-Control Teleoperation Paradigms on a Soft Growing Robot Manipulator

Aug 02, 2021

Abstract:Semi-autonomous telerobotic systems allow both humans and robots to exploit their strengths, while enabling personalized execution of a task. However, for new soft robots with degrees of freedom dissimilar to those of human operators, it is unknown how the control of a task should be divided between the human and robot. This work presents a set of interaction paradigms between a human and a soft growing robot manipulator, and demonstrates them in both real and simulated scenarios. The robot can grow and retract by eversion and inversion of its tubular body, a property we exploit to implement interaction paradigms. We implemented and tested six different paradigms of human-robot interaction, beginning with full teleoperation and gradually adding automation to various aspects of the task execution. All paradigms were demonstrated by two expert and two naive operators. Results show that humans and the soft robot manipulator can split control along degrees of freedom while acting simultaneously. In the simple pick-and-place task studied in this work, performance improves as the control is gradually given to the robot, because the robot can correct certain human errors. However, human engagement and enjoyment may be maximized when the task is at least partially shared. Finally, when the human operator is assisted by haptic feedback based on soft robot position errors, we observed that the improvement in performance is highly dependent on the expertise of the human operator.

A Dynamics Simulator for Soft Growing Robots

Nov 03, 2020

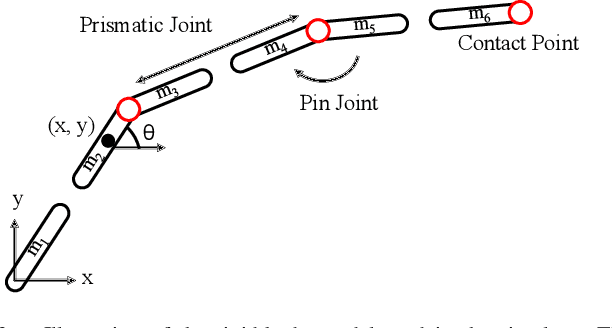

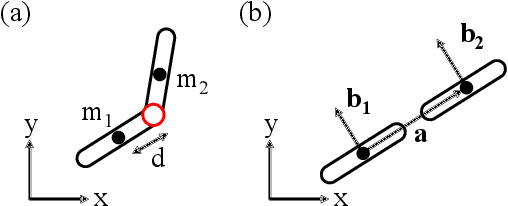

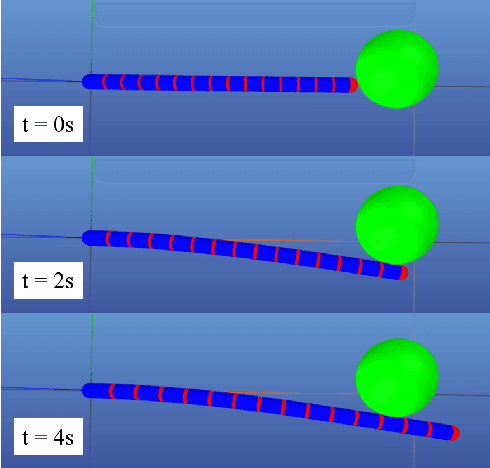

Abstract:Simulating soft robots in cluttered environments remains an open problem due to the challenge of capturing complex dynamics and interactions with the environment. Furthermore, fast simulation is desired for quickly exploring robot behaviors in the context of motion planning. In this paper, we examine a particular class of inflated-beam soft growing robots called "vine robots", and present a dynamics simulator that captures general behaviors, handles robot-object interactions, and runs faster than real time. The simulator framework uses a simplified multi-link, rigid-body model with contact constraints. To narrow the sim-to-real gap, we develop methods for fitting model parameters based on video data of a robot in motion and in contact with an environment. We provide examples of simulations, including several with fit parameters, to show the qualitative and quantitative agreement between simulated and real behaviors. Our work demonstrates the capabilities of this high-speed dynamics simulator and its potential for use in the control of soft robots.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge