Dezhong Tong

Highly Deformable Proprioceptive Membrane for Real-Time 3D Shape Reconstruction

Jan 20, 2026Abstract:Reconstructing the three-dimensional (3D) geometry of object surfaces is essential for robot perception, yet vision-based approaches are generally unreliable under low illumination or occlusion. This limitation motivates the design of a proprioceptive membrane that conforms to the surface of interest and infers 3D geometry by reconstructing its own deformation. Conventional shape-aware membranes typically rely on resistive, capacitive, or magneto-sensitive mechanisms. However, these methods often encounter challenges such as structural complexity, limited compliance during large-scale deformation, and susceptibility to electromagnetic interference. This work presents a soft, flexible, and stretchable proprioceptive silicone membrane based on optical waveguide sensing. The membrane sensor integrates edge-mounted LEDs and centrally distributed photodiodes (PDs), interconnected via liquid-metal traces embedded within a multilayer elastomeric composite. Rich deformation-dependent light intensity signals are decoded by a data-driven model to recover the membrane geometry as a 3D point cloud. On a customized 140 mm square membrane, real-time reconstruction of large-scale out-of-plane deformation is achieved at 90 Hz with an average reconstruction error of 1.3 mm, measured by Chamfer distance, while maintaining accuracy for indentations up to 25 mm. The proposed framework provides a scalable, robust, and low-profile solution for global shape perception in deformable robotic systems.

Rapidly Learning Soft Robot Control via Implicit Time-Stepping

Nov 10, 2025

Abstract:With the explosive growth of rigid-body simulators, policy learning in simulation has become the de facto standard for most rigid morphologies. In contrast, soft robotic simulation frameworks remain scarce and are seldom adopted by the soft robotics community. This gap stems partly from the lack of easy-to-use, general-purpose frameworks and partly from the high computational cost of accurately simulating continuum mechanics, which often renders policy learning infeasible. In this work, we demonstrate that rapid soft robot policy learning is indeed achievable via implicit time-stepping. Our simulator of choice, DisMech, is a general-purpose, fully implicit soft-body simulator capable of handling both soft dynamics and frictional contact. We further introduce delta natural curvature control, a method analogous to delta joint position control in rigid manipulators, providing an intuitive and effective means of enacting control for soft robot learning. To highlight the benefits of implicit time-stepping and delta curvature control, we conduct extensive comparisons across four diverse soft manipulator tasks against one of the most widely used soft-body frameworks, Elastica. With implicit time-stepping, parallel stepping of 500 environments achieves up to 6x faster speeds for non-contact cases and up to 40x faster for contact-rich scenarios. Finally, a comprehensive sim-to-sim gap evaluation--training policies in one simulator and evaluating them in another--demonstrates that implicit time-stepping provides a rare free lunch: dramatic speedups achieved without sacrificing accuracy.

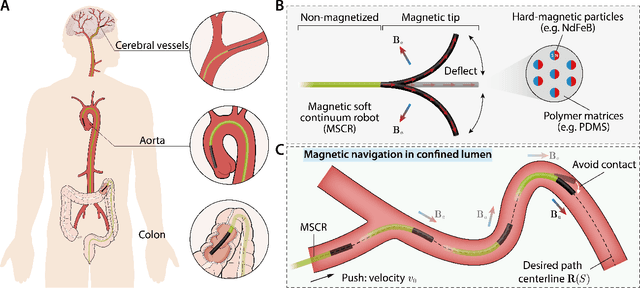

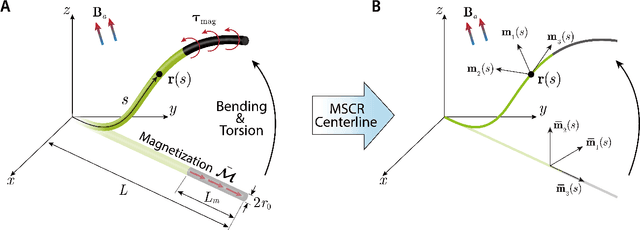

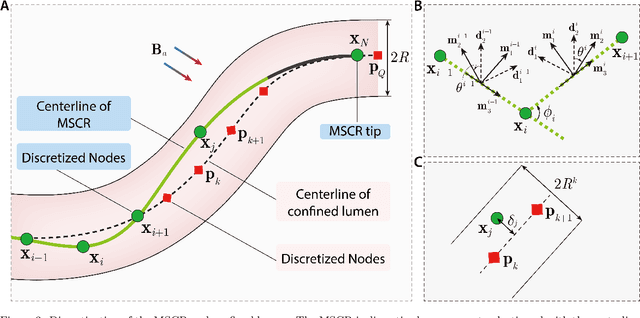

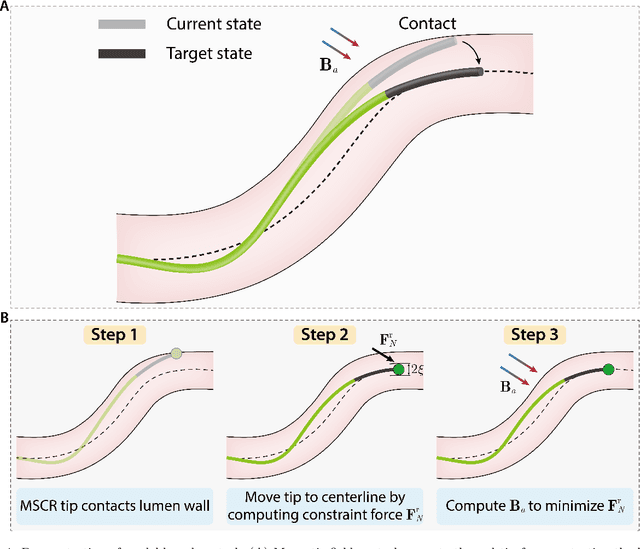

Real-time simulation enabled navigation control of magnetic soft continuum robots in confined lumens

Mar 11, 2025

Abstract:Magnetic soft continuum robots (MSCRs) have emerged as a promising technology for minimally invasive interventions, offering enhanced dexterity and remote-controlled navigation in confined lumens. Unlike conventional guidewires with pre-shaped tips, MSCRs feature a magnetic tip that actively bends under applied magnetic fields. Despite extensive studies in modeling and simulation, achieving real-time navigation control of MSCRs in confined lumens remains a significant challenge. The primary reasons are due to robot-lumen contact interactions and computational limitations in modeling MSCR nonlinear behavior under magnetic actuation. Existing approaches, such as Finite Element Method (FEM) simulations and energy-minimization techniques, suffer from high computational costs and oversimplified contact interactions, making them impractical for real-world applications. In this work, we develop a real-time simulation and navigation control framework that integrates hard-magnetic elastic rod theory, formulated within the Discrete Differential Geometry (DDG) framework, with an order-reduced contact handling strategy. Our approach captures large deformations and complex interactions while maintaining computational efficiency. Next, the navigation control problem is formulated as an inverse design task, where optimal magnetic fields are computed in real time by minimizing the constrained forces and enhancing navigation accuracy. We validate the proposed framework through comprehensive numerical simulations and experimental studies, demonstrating its robustness, efficiency, and accuracy. The results show that our method significantly reduces computational costs while maintaining high-fidelity modeling, making it feasible for real-time deployment in clinical settings.

Harnessing Discrete Differential Geometry: A Virtual Playground for the Bilayer Soft Robotics

Feb 02, 2025Abstract:Soft robots have garnered significant attention due to their promising applications across various domains. A hallmark of these systems is their bilayer structure, where strain mismatch caused by differential expansion between layers induces complex deformations. Despite progress in theoretical modeling and numerical simulation, accurately capturing their dynamic behavior, especially during environmental interactions, remains challenging. This study presents a novel simulation environment based on the Discrete Elastic Rod (DER) model to address the challenge. By leveraging discrete differential geometry (DDG), the DER approach offers superior convergence compared to conventional methods like Finite Element Method (FEM), particularly in handling contact interactions -- an essential aspect of soft robot dynamics in real-world scenarios. Our simulation framework incorporates key features of bilayer structures, including stretching, bending, twisting, and inter-layer coupling. This enables the exploration of a wide range of dynamic behaviors for bilayer soft robots, such as gripping, crawling, jumping, and swimming. The insights gained from this work provide a robust foundation for the design and control of advanced bilayer soft robotic systems.

Inverse Design of Snap-Actuated Jumping Robots Powered by Mechanics-Aided Machine Learning

Aug 20, 2024

Abstract:Exploring the design and control strategies of soft robots through simulation is highly attractive due to its cost-effectiveness. Although many existing models (e.g., finite element analysis) are effective for simulating soft robotic dynamics, there remains a need for a general and efficient numerical simulation approach in the soft robotics community. In this paper, we develop a discrete differential geometry-based numerical framework to achieve the model-based inverse design of a novel snap-actuated jumping robot. It is found that the dynamic process of a snapping beam can be either symmetric or asymmetric, such that the trajectory of the jumping robot can be tunable (e.g., horizontal or vertical). By employing this novel mechanism of the bistable beam as the robotic actuator, we next propose a physics-data hybrid inverse design strategy for the snap-jump robot with a broad spectrum of jumping capabilities. We first use the physical engine to study the influences of the robot's design parameters on the jumping capabilities, then generate extensive simulation data to formulate a data-driven inverse design solution. The inverse design solution can rapidly explore the combination of design parameters for achieving a target jump, which provides valuable guidance for the fabrication and control of the jumping robot. The proposed methodology paves the way for exploring the design and control insights of soft robots with the help of simulations.

Sim2Real Physically Informed Neural Controllers for Robotic Deployment of Deformable Linear Objects

Mar 05, 2023Abstract:Deformable linear objects, such as rods, cables, and ropes, play important roles in daily life. However, manipulation of DLOs is challenging as large geometrically nonlinear deformations may occur during the manipulation process. This problem is made even more difficult as the different deformation modes (e.g., stretching, bending, and twisting) may result in elastic instabilities during manipulation. In this paper, we formulate a physics-guided data-driven method to solve a challenging manipulation task -- accurately deploying a DLO (an elastic rod) onto a rigid substrate along various prescribed patterns. Our framework combines machine learning, scaling analysis, and physics-based simulations to develop a physically informed neural controller for deployment. We explore the complex interplay between the gravitational and elastic energies of the manipulated DLO and obtain a control method for DLO deployment that is robust against friction and material properties. Out of the numerous geometrical and material properties of the rod and substrate, we show that only three non-dimensional parameters are needed to describe the deployment process with physical analysis. Therefore, the essence of the controlling law for the manipulation task can be constructed with a low-dimensional model, drastically increasing the computation speed. The effectiveness of our optimal control scheme is shown through a comprehensive robotic case study comparing against a heuristic control method for deploying rods for a wide variety of patterns. In addition to this, we also showcase the practicality of our control scheme by having a robot accomplish challenging high-level tasks such as mimicking human handwriting and tying knots.

mBEST: Realtime Deformable Linear Object Detection Through Minimal Bending Energy Skeleton Pixel Traversals

Feb 18, 2023Abstract:Robotic manipulation of deformable materials is a challenging task that often requires realtime visual feedback. This is especially true for deformable linear objects (DLOs) or "rods", whose slender and flexible structures make proper tracking and detection nontrivial. To address this challenge, we present mBEST, a robust algorithm for the realtime detection of DLOs that is capable of producing an ordered pixel sequence of each DLO's centerline along with segmentation masks. Our algorithm obtains a binary mask of the DLOs and then thins it to produce a skeleton pixel representation. After refining the skeleton to ensure topological correctness, the pixels are traversed to generate paths along each unique DLO. At the core of our algorithm, we postulate that intersections can be robustly handled by choosing the combination of paths that minimizes the cumulative bending energy of the DLO(s). We show that this simple and intuitive formulation outperforms the state-of-the-art methods for detecting DLOs with large numbers of sporadic crossings and curvatures with high variance. Furthermore, our method achieves a significant performance improvement of approximately 40 FPS compared to the 15 FPS of prior algorithms, which enables realtime applications.

Deep Learning of Force Manifolds from the Simulated Physics of Robotic Paper Folding

Jan 05, 2023

Abstract:Robotic manipulation of slender objects is challenging, especially when the induced deformations are large and nonlinear. Traditionally, learning-based control approaches, e.g., imitation learning, have been used to tackle deformable material manipulation. Such approaches lack generality and often suffer critical failure from a simple switch of material, geometric, and/or environmental (e.g., friction) properties. In this article, we address a fundamental but difficult step of robotic origami: forming a predefined fold in paper with only a single manipulator. A data-driven framework combining physically-accurate simulation and machine learning is used to train deep neural network models capable of predicting the external forces induced on the paper given a grasp position. We frame the problem using scaling analysis, resulting in a control framework robust against material and geometric changes. Path planning is carried out over the generated manifold to produce robot manipulation trajectories optimized to prevent sliding. Furthermore, the inference speed of the trained model enables the incorporation of real-time visual feedback to achieve closed-loop sensorimotor control. Real-world experiments demonstrate that our framework can greatly improve robotic manipulation performance compared against natural paper folding strategies, even when manipulating paper objects of various materials and shapes.

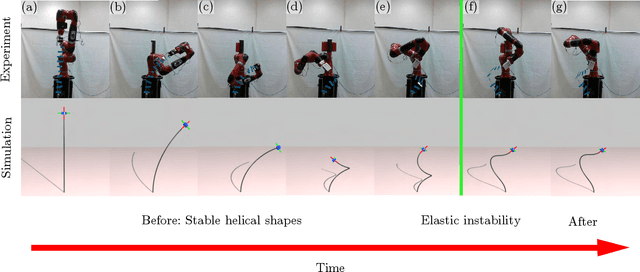

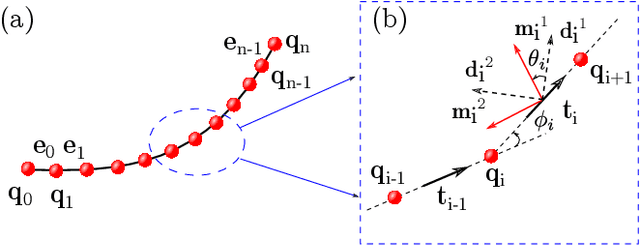

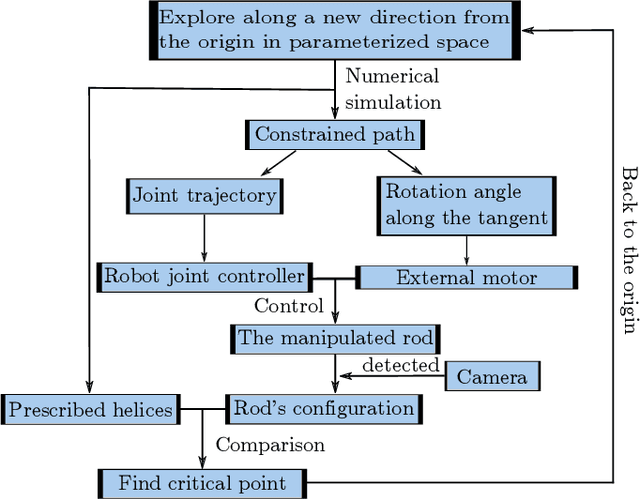

Automated stability testing of elastic rods with helical centerlines using a robotic system

Dec 16, 2021

Abstract:Experimental analysis of the mechanics of a deformable object, and particularly its stability, requires repetitive testing and, depending on the complexity of the object's shape, a testing setup that can manipulate many degrees of freedom at the object's boundary. Motivated by recent advancements in robotic manipulation of deformable objects, this paper addresses these challenges by constructing a method for automated stability testing of a slender elastic rod -- a canonical example of a deformable object -- using a robotic system. We focus on rod configurations with helical centerlines since the stability of a helical rod can be described using only three parameters, but experimentally determining the stability requires manipulation of both the position and orientation at one end of the rod, which is not possible using traditional experimental methods that only actuate a limited number of degrees of freedom. Using a recent geometric characterization of stability for helical rods, we construct and implement a manipulation scheme to explore the space of stable helices, and we use a vision system to detect the onset of instabilities within this space. The experimental results obtained by our automated testing system show good agreement with numerical simulations of elastic rods in helical configurations. The methods described in this paper lay the groundwork for automation to grow within the field of experimental mechanics.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge