Chen-Lung Lu

Multi-Robot Scan-n-Print for Wire Arc Additive Manufacturing

Nov 24, 2024

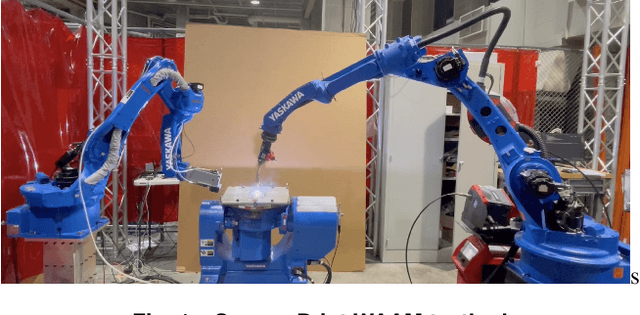

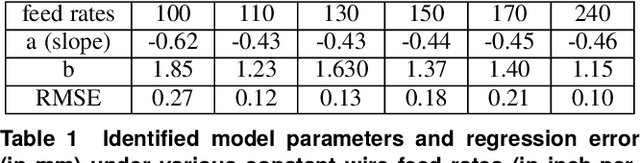

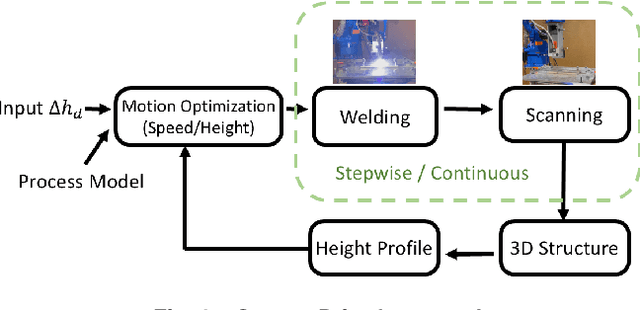

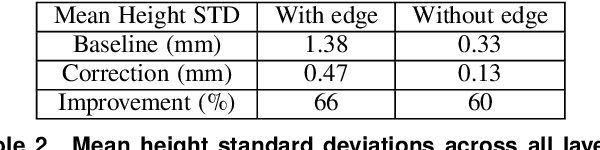

Abstract:Robotic Wire Arc Additive Manufacturing (WAAM) is a metal additive manufacturing technology, offering flexible 3D printing while ensuring high quality near-net-shape final parts. However, WAAM also suffers from geometric imprecision, especially for low-melting-point metal such as aluminum alloys. In this paper, we present a multi-robot framework for WAAM process monitoring and control. We consider a three-robot setup: a 6-dof welding robot, a 2-dof trunnion platform, and a 6-dof sensing robot with a wrist-mounted laser line scanner measuring the printed part height profile. The welding parameters, including the wire feed rate, are held constant based on the materials used, so the control input is the robot path speed. The measured output is the part height profile. The planning phase decomposes the target shape into slices of uniform height. During runtime, the sensing robot scans each printed layer, and the robot path speed for the next layer is adjusted based on the deviation from the desired profile. The adjustment is based on an identified model correlating the path speed to change in height. The control architecture coordinates the synchronous motion and data acquisition between all robots and sensors. Using a three-robot WAAM testbed, we demonstrate significant improvements of the closed loop scan-n-print approach over the current open loop result on both a flat wall and a more complex turbine blade shape.

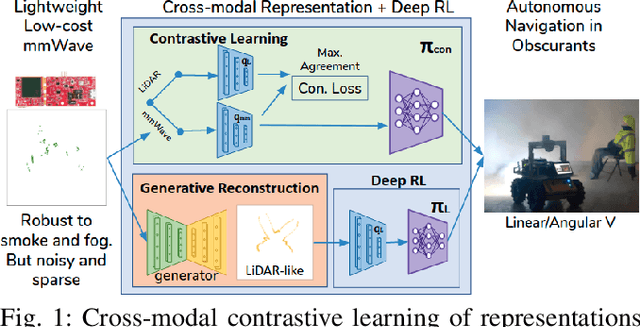

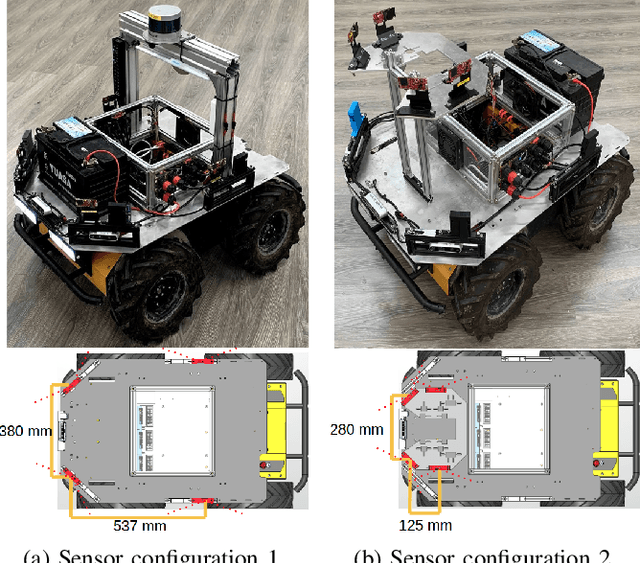

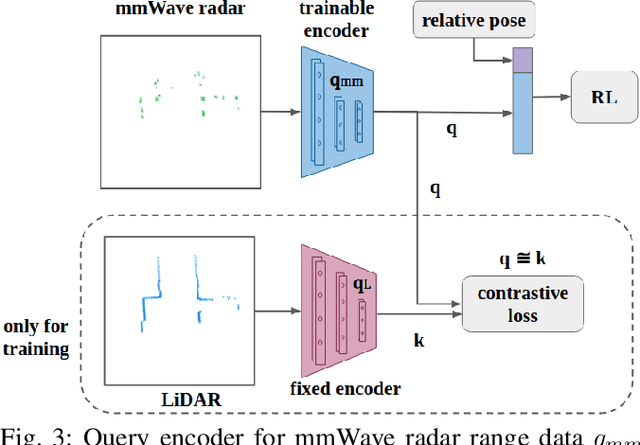

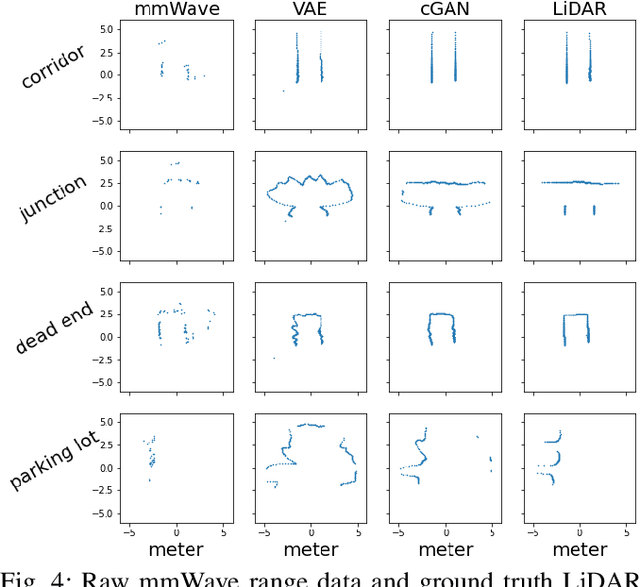

Cross-Modal Contrastive Learning of Representations for Navigation using Lightweight, Low-Cost Millimeter Wave Radar for Adverse Environmental Conditions

Jan 10, 2021

Abstract:Deep reinforcement learning (RL), where the agent learns from mistakes, has been successfully applied to a variety of tasks. With the aim of learning collision-free policies for unmanned vehicles, deep RL has been used for training with various types of data, such as colored images, depth images, and LiDAR point clouds, without the use of classic map--localize--plan approaches. However, existing methods are limited by their reliance on cameras and LiDAR devices, which have degraded sensing under adverse environmental conditions (e.g., smoky environments). In response, we propose the use of single-chip millimeter-wave (mmWave) radar, which is lightweight and inexpensive, for learning-based autonomous navigation. However, because mmWave radar signals are often noisy and sparse, we propose a cross-modal contrastive learning for representation (CM-CLR) method that maximizes the agreement between mmWave radar data and LiDAR data in the training stage. We evaluated our method in real-world robot compared with 1) a method with two separate networks using cross-modal generative reconstruction and an RL policy and 2) a baseline RL policy without cross-modal representation. Our proposed end-to-end deep RL policy with contrastive learning successfully navigated the robot through smoke-filled maze environments and achieved better performance compared with generative reconstruction methods, in which noisy artifact walls or obstacles were produced. All pretrained models and hardware settings are open access for reproducing this study and can be obtained at https://arg-nctu.github.io/projects/deeprl-mmWave.html

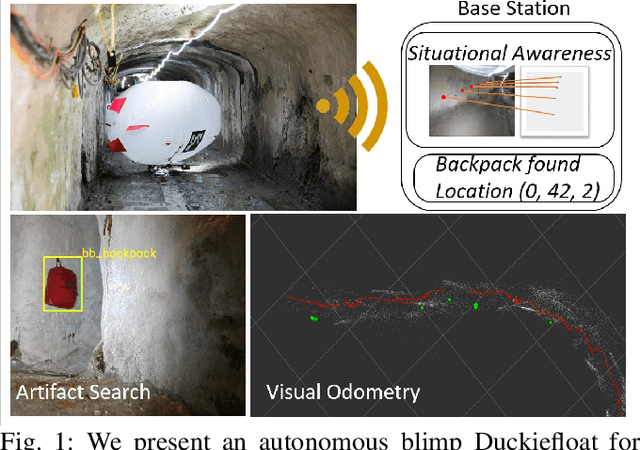

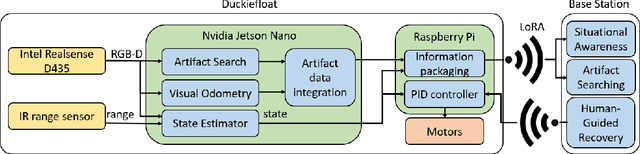

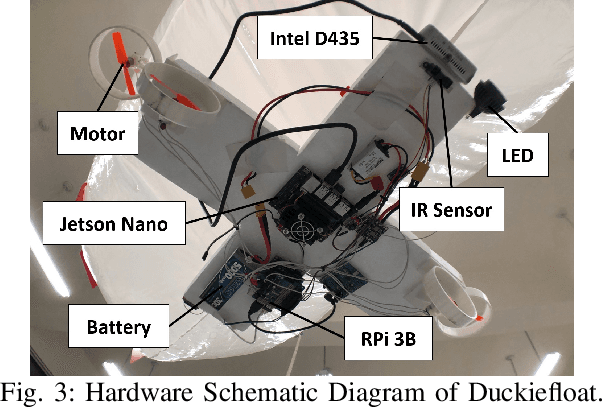

Duckiefloat: a Collision-Tolerant Resource-Constrained Blimp for Long-Term Autonomy in Subterranean Environments

Oct 31, 2019

Abstract:There are several challenges for search and rescue robots: mobility, perception, autonomy, and communication. Inspired by the DARPA Subterranean (SubT) Challenge, we propose an autonomous blimp robot, which has the advantages of low power consumption and collision-tolerance compared to other aerial vehicles like drones. This is important for search and rescue tasks that usually last for one or more hours. However, the underground constrained passages limit the size of blimp envelope and its payload, making the proposed system resource-constrained. Therefore, a careful design consideration is needed to build a blimp system with on-board artifact search and SLAM. In order to reach long-term operation, a failure-aware algorithm with minimal communication to human supervisor to have situational awareness and send control signals to the blimp when needed.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge