Beiwen Li

Comprehensive Machine Learning Benchmarking for Fringe Projection Profilometry with Photorealistic Synthetic Data

Jan 13, 2026Abstract:Machine learning approaches for fringe projection profilometry (FPP) are hindered by the lack of large, diverse datasets and comprehensive benchmarking protocols. This paper introduces the first open-source, photorealistic synthetic dataset for FPP, generated using NVIDIA Isaac Sim with 15,600 fringe images and 300 depth reconstructions across 50 diverse objects. We benchmark four neural network architectures (UNet, Hformer, ResUNet, Pix2Pix) on single-shot depth reconstruction, revealing that all models achieve similar performance (58-77 mm RMSE) despite substantial architectural differences. Our results demonstrate fundamental limitations of direct fringe-to-depth mapping without explicit phase information, with reconstruction errors approaching 75-95\% of the typical object depth range. This resource provides standardized evaluation protocols enabling systematic comparison and development of learning-based FPP approaches.

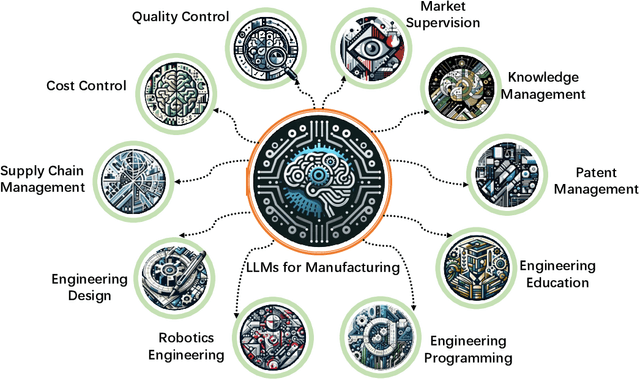

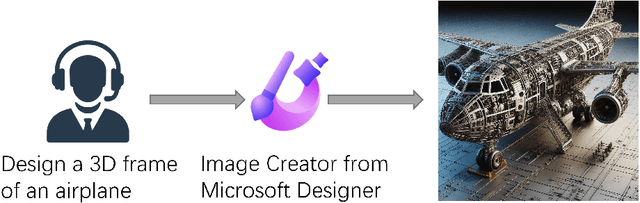

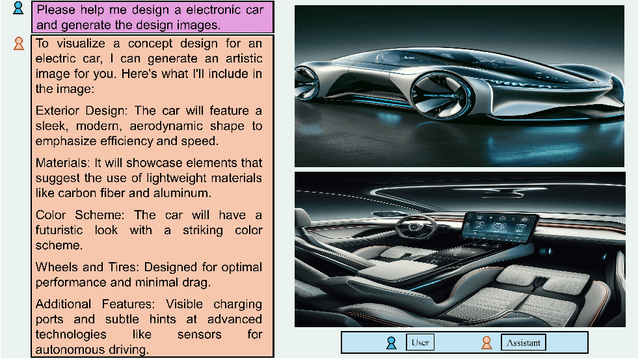

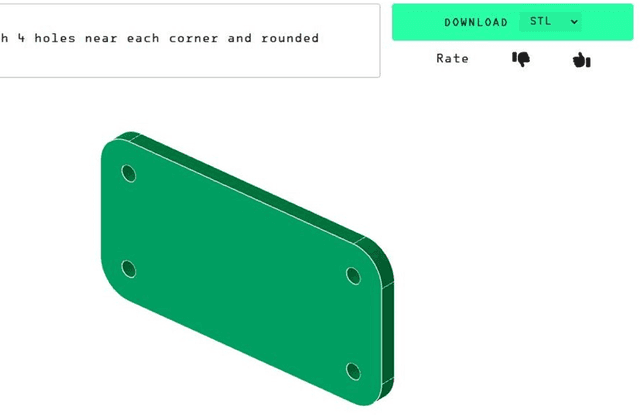

Large Language Models for Manufacturing

Oct 28, 2024

Abstract:The rapid advances in Large Language Models (LLMs) have the potential to transform manufacturing industry, offering new opportunities to optimize processes, improve efficiency, and drive innovation. This paper provides a comprehensive exploration of the integration of LLMs into the manufacturing domain, focusing on their potential to automate and enhance various aspects of manufacturing, from product design and development to quality control, supply chain optimization, and talent management. Through extensive evaluations across multiple manufacturing tasks, we demonstrate the remarkable capabilities of state-of-the-art LLMs, such as GPT-4V, in understanding and executing complex instructions, extracting valuable insights from vast amounts of data, and facilitating knowledge sharing. We also delve into the transformative potential of LLMs in reshaping manufacturing education, automating coding processes, enhancing robot control systems, and enabling the creation of immersive, data-rich virtual environments through the industrial metaverse. By highlighting the practical applications and emerging use cases of LLMs in manufacturing, this paper aims to provide a valuable resource for professionals, researchers, and decision-makers seeking to harness the power of these technologies to address real-world challenges, drive operational excellence, and unlock sustainable growth in an increasingly competitive landscape.

Grasping Force Control and Adaptation for a Cable-Driven Robotic Hand

Jul 27, 2024Abstract:This paper introduces a unique force control and adaptation algorithm for a lightweight and low-complexity five-fingered robotic hand, namely an Integrated-Finger Robotic Hand (IFRH). The force control and adaptation algorithm is intuitive to design, easy to implement, and improves the grasping functionality through feedforward adaptation automatically. Specifically, we have extended Youla-parameterization which is traditionally used in feedback controller design into a feedforward iterative learning control algorithm (ILC). The uniqueness of such an extension is that both the feedback and feedforward controllers are parameterized over one unified design parameter which can be easily customized based on the desired closed-loop performance. While Youla-parameterization and ILC have been explored in the past on various applications, our unique parameterization and computational methods make the design intuitive and easy to implement. This provides both robust and adaptive learning capabilities, and our application rivals the complexity of many robotic hand control systems. Extensive experimental tests have been conducted to validate the effectiveness of our method.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge