Yayun Du

Deep-CNN based Robotic Multi-Class Under-Canopy Weed Control in Precision Farming

Dec 28, 2021

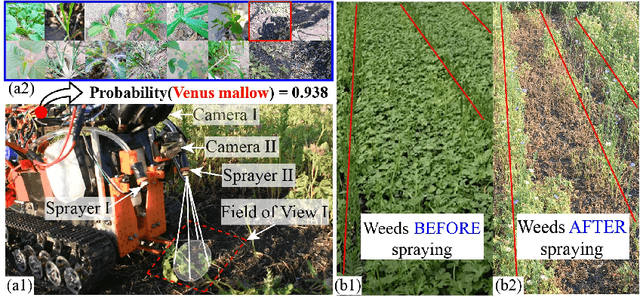

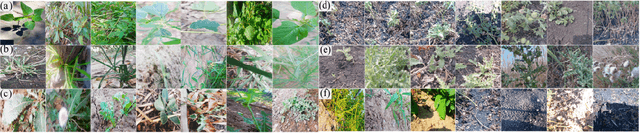

Abstract:Smart weeding systems to perform plant-specific operations can contribute to the sustainability of agriculture and the environment. Despite monumental advances in autonomous robotic technologies for precision weed management in recent years, work on under-canopy weeding in fields is yet to be realized. A prerequisite of such systems is reliable detection and classification of weeds to avoid mistakenly spraying and, thus, damaging the surrounding plants. Real-time multi-class weed identification enables species-specific treatment of weeds and significantly reduces the amount of herbicide use. Here, our first contribution is the first adequately large realistic image dataset \textit{AIWeeds} (one/multiple kinds of weeds in one image), a library of about 10,000 annotated images of flax, and the 14 most common weeds in fields and gardens taken from 20 different locations in North Dakota, California, and Central China. Second, we provide a full pipeline from model training with maximum efficiency to deploying the TensorRT-optimized model onto a single board computer. Based on \textit{AIWeeds} and the pipeline, we present a baseline for classification performance using five benchmark CNN models. Among them, MobileNetV2, with both the shortest inference time and lowest memory consumption, is the qualified candidate for real-time applications. Finally, we deploy MobileNetV2 onto our own compact autonomous robot \textit{SAMBot} for real-time weed detection. The 90\% test accuracy realized in previously unseen scenes in flax fields (with a row spacing of 0.2-0.3 m), with crops and weeds, distortion, blur, and shadows, is a milestone towards precision weed control in the real world. We have publicly released the dataset and code to generate the results at \url{https://github.com/StructuresComp/Multi-class-Weed-Classification}.

Mechanics-based Analysis on Flagellated Robots

Dec 27, 2021

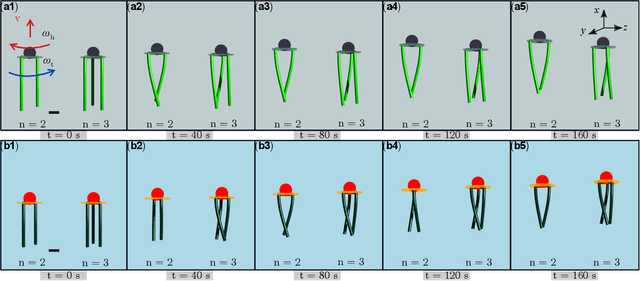

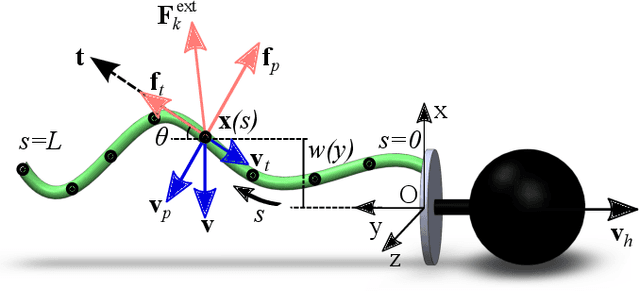

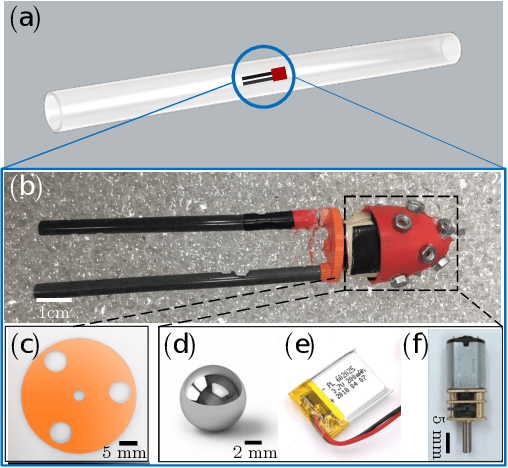

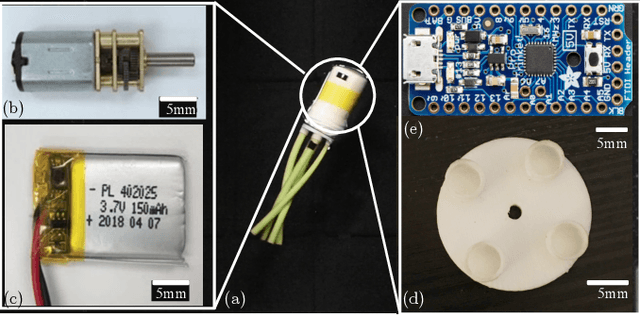

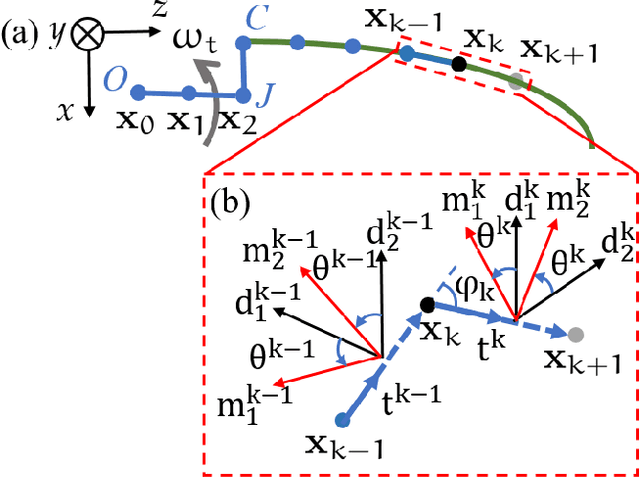

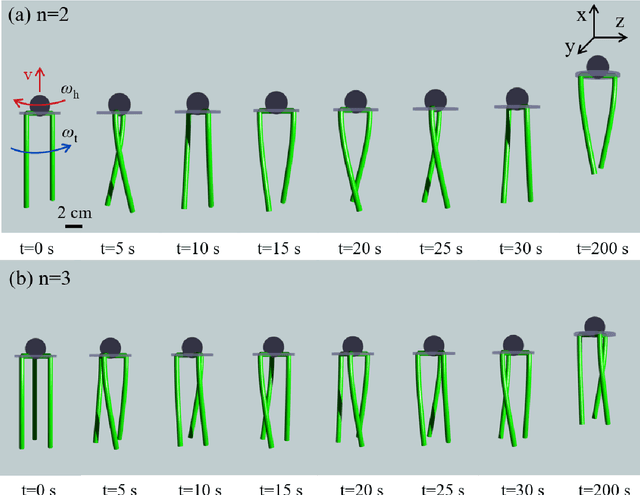

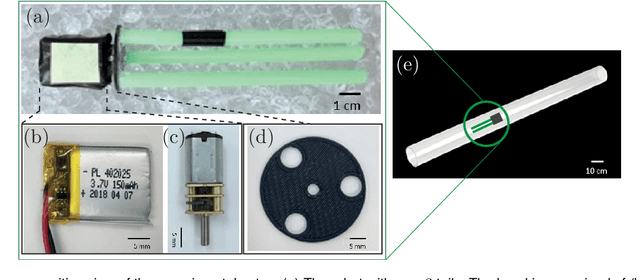

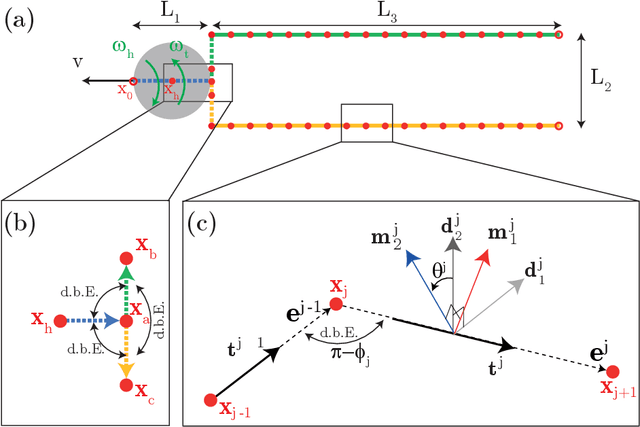

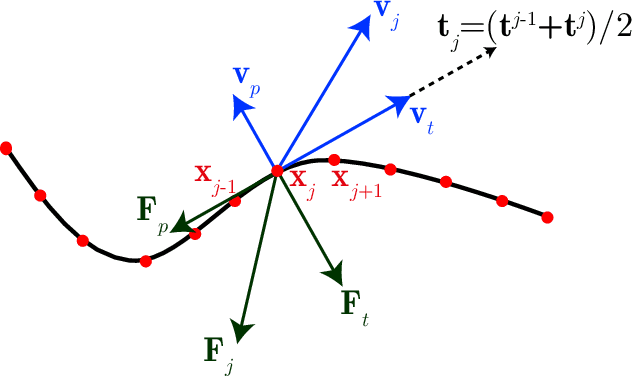

Abstract:We explore the locomotion of soft robots in granular medium (GM) resulting from the elastic deformation of slender rods. A low-cost, rapidly fabricable robot inspired by the physiological structure of bacteria is presented. It consists of a rigid head, with a motor and batteries embedded, and multiple elastic rods (our model for flagella) to investigate locomotion in GM. The elastic flagella are rotated at one end by the motor, and they deform due to the drag from GM, propelling the robot. The external drag is determined by the flagellar shape, while the latter changes due to the competition between external loading and elastic forces. In this coupled fluid-structure interaction problem, we observe that increasing the number of flagella can decrease or increase the propulsive speed of the robot, depending on the physical parameters of the system. This nonlinearity in the functional relation between propulsion and the parameters of this simple robot motivates us to fundamentally analyze its mechanics using theory, numerical simulation, and experiments. We present a simple Euler-Bernoulli beam theory-based analytical framework that is capable of qualitatively capturing both cases. Theoretical prediction quantitatively matches experiments when the flagellar deformation is small. To account for the geometrically nonlinear deformation often encountered in soft robots and microbes, we implement a simulation framework that incorporates discrete differential geometry-based simulations of elastic rods, a resistive force theory-based model for drag, and a modified Stokes law for the hydrodynamics of the robot head. Comparison with experimental data indicates that the simulations can quantitatively predict robotic motion. Overall, the theoretical and numerical tools presented in this paper can shed light on the design and control of this class of articulated robots in granular or fluid media.

A Low-cost Robot with Autonomous Recharge and Navigation for Weed Control in Fields with Narrow Row Spacing

Dec 03, 2021

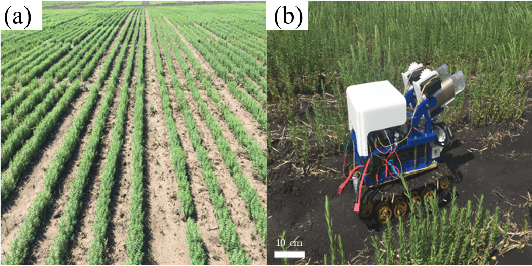

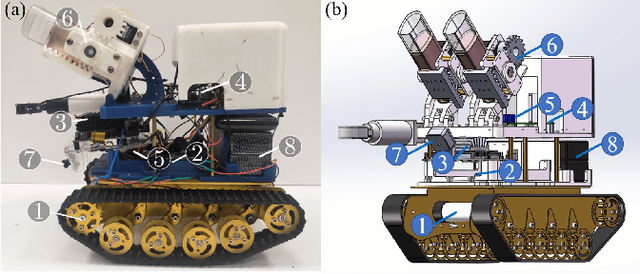

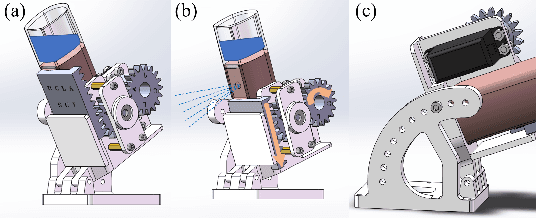

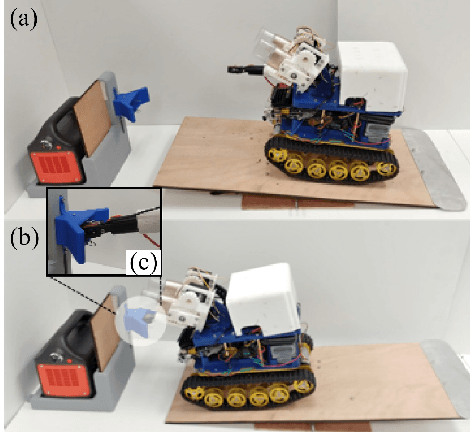

Abstract:Modern herbicide application in agricultural settings typically relies on either large scale sprayers that dispense herbicide over crops and weeds alike or portable sprayers that require labor intensive manual operation. The former method results in overuse of herbicide and reduction in crop yield while the latter is often untenable in large scale operations. This paper presents the first fully autonomous robot for weed management for row crops capable of computer vision based navigation, weed detection, complete field coverage, and automatic recharge for under \$400. The target application is autonomous inter-row weed control in crop fields, e.g. flax and canola, where the spacing between croplines is as small as one foot. The proposed robot is small enough to pass between croplines at all stages of plant growth while detecting weeds and spraying herbicide. A recharging system incorporates newly designed robotic hardware, a ramp, a robotic charging arm, and a mobile charging station. An integrated vision algorithm is employed to assist with charger alignment effectively. Combined, they enable the robot to work continuously in the field without access to electricity. In addition, a color-based contour algorithm combined with preprocessing techniques is applied for robust navigation relying on the input from the onboard monocular camera. Incorporating such compact robots into farms could help automate weed control, even during late stages of growth, and reduce herbicide use by targeting weeds with precision. The robotic platform is field-tested in the flaxseed fields of North Dakota.

Simple Flagellated Soft Robot for Locomotion near Air-Fluid Interface

Mar 09, 2021

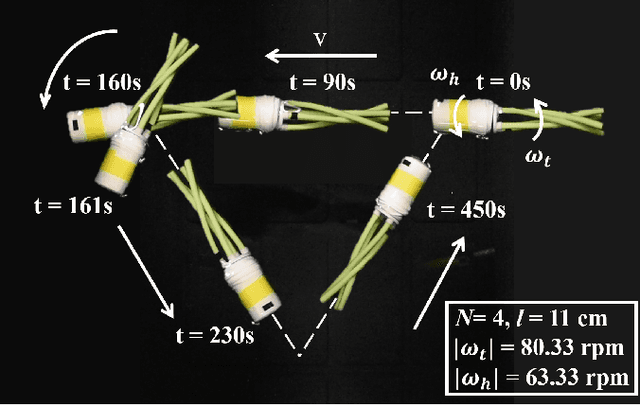

Abstract:A wide range of microorganisms, e.g. bacteria, propel themselves by rotation of soft helical tails, also known as flagella. Due to the small size of these organisms, viscous forces overwhelm inertial effects and the flow is at low Reynolds number. In this fluid-structure problem, a competition between elastic forces and hydrodynamic (viscous) forces leads to a net propulsive force forward. A thorough understanding of this highly coupled fluid-structure interaction problem can not only help us better understand biological propulsion but also help us design bio-inspired functional robots with applications in oil spill cleanup, water quality monitoring, and infrastructure inspection. Here, we introduce arguably the simplest soft robot with a single binary control signal, which is capable of moving along an arbitrary 2D trajectory near air-fluid interface and at the interface between two fluids. The robot exploits the variation in viscosity to move along the prescribed trajectory. Our analysis of this newly introduced soft robot consists of three main components. First, we fabricate this simple robot and use it as an experimental testbed. Second, a discrete differential geometry-based modeling framework is used for simulation of the robot. Upon validation of the simulation tool, the third part of this study employs the simulations to develop a control scheme with a single binary input to make the robot follow any prescribed path.

Modeling the locomotion of articulated soft robots in granular medium

Mar 06, 2021

Abstract:Soft robots, in contrast to their rigid counter parts, have infinite degrees of freedom that are coupled with their interaction with the environment. We consider the locomotion of an untethered robot, in the granular medium, comprised of multiple flexible flagella that rotate about an axis by a motor. Drag from the grains causes the flagella to deform and the deformed shape generates a net forward propulsion. This external drag force depends on the shape of the flagella, while the change in flagellar shape is the result of the competition between the external loading and elastic forces. We introduce a numerical tool that couples discrete differential geometry based simulation of elastic rods - our model for flagella - and a resistive force theory based model for the drag. In parallel with simulations, we conduct experiments to quantify the propulsive speed of this class of robots. We find reasonable quantitative agreement between experiments and simulations. Owing to a rod-based kinematic representation of the robot, the simulation runs faster than real-time, and, therefore, we can use it as a design tool for this class of soft robots. We find that there is an optimal rotational speed at which maximum efficiency is achieved. Moreover, both experiments and simulations show that increasing the number of flagella decreases the speed of the robot. We also gain insight into the mechanics of granular medium - while resistive force theory can successfully describe the propulsion at low number of flagella, it fails when more flagella are added to the robot.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge