Tommy Hu

Safe Motion Planning in Unknown Environments: Optimality Benchmarks and Tractable Policies

Apr 16, 2018

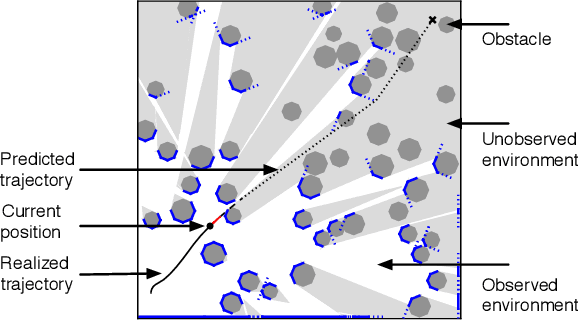

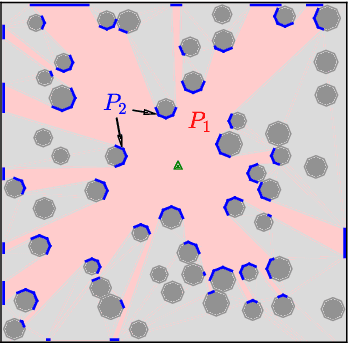

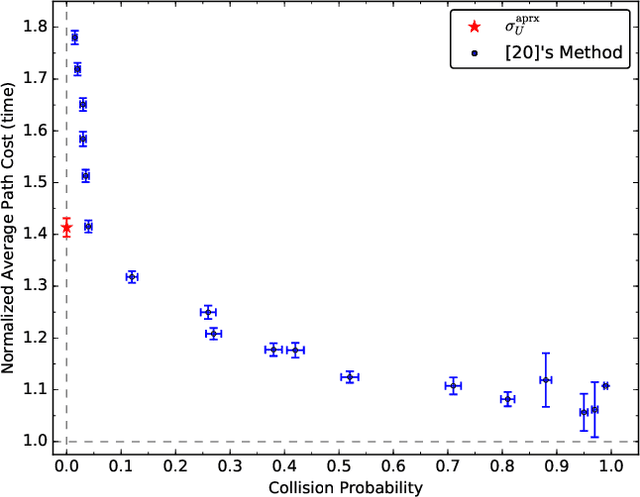

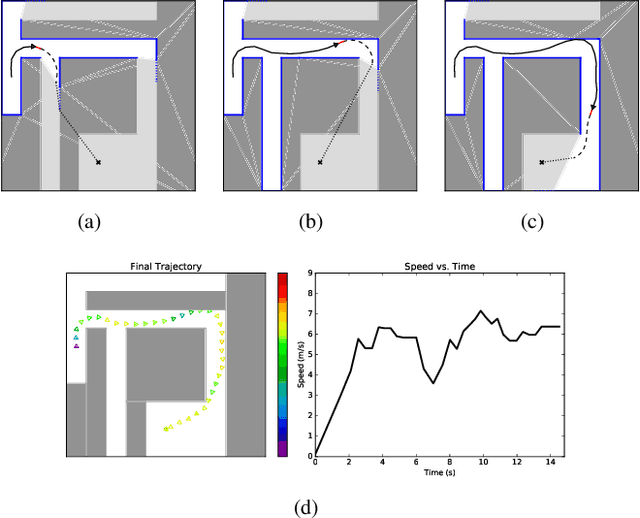

Abstract:This paper addresses the problem of planning a safe (i.e., collision-free) trajectory from an initial state to a goal region when the obstacle space is a-priori unknown and is incrementally revealed online, e.g., through line-of-sight perception. Despite its ubiquitous nature, this formulation of motion planning has received relatively little theoretical investigation, as opposed to the setup where the environment is assumed known. A fundamental challenge is that, unlike motion planning with known obstacles, it is not even clear what an optimal policy to strive for is. Our contribution is threefold. First, we present a notion of optimality for safe planning in unknown environments in the spirit of comparative (as opposed to competitive) analysis, with the goal of obtaining a benchmark that is, at least conceptually, attainable. Second, by leveraging this theoretical benchmark, we derive a pseudo-optimal class of policies that can seamlessly incorporate any amount of prior or learned information while still guaranteeing the robot never collides. Finally, we demonstrate the practicality of our algorithmic approach in numerical experiments using a range of environment types and dynamics, including a comparison with a state of the art method. A key aspect of our framework is that it automatically and implicitly weighs exploration versus exploitation in a way that is optimal with respect to the information available.

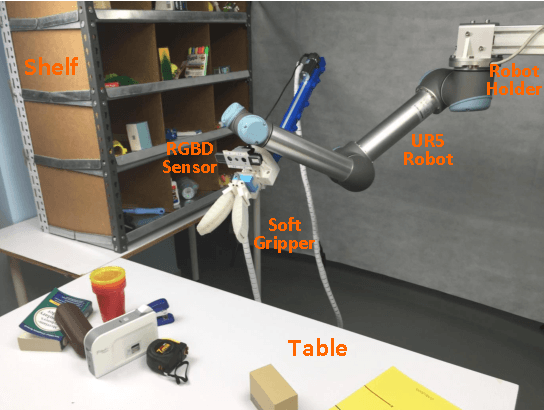

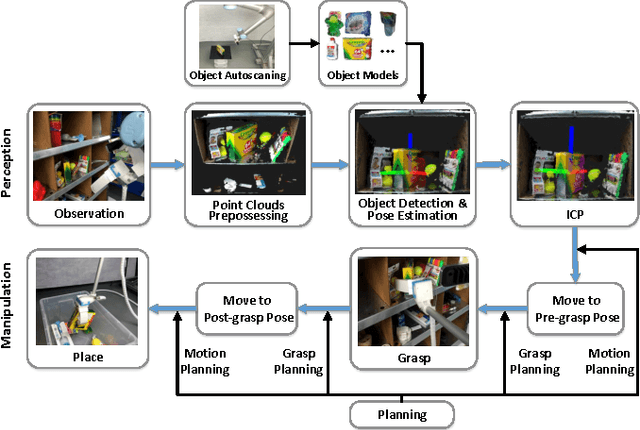

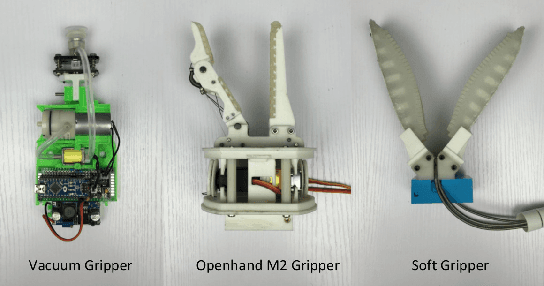

DoraPicker: An Autonomous Picking System for General Objects

Mar 21, 2016

Abstract:Robots that autonomously manipulate objects within warehouses have the potential to shorten the package delivery time and improve the efficiency of the e-commerce industry. In this paper, we present a robotic system that is capable of both picking and placing general objects in warehouse scenarios. Given a target object, the robot autonomously detects it from a shelf or a table and estimates its full 6D pose. With this pose information, the robot picks the object using its gripper, and then places it into a container or at a specified location. We describe our pick-and-place system in detail while highlighting our design principles for the warehouse settings, including the perception method that leverages knowledge about its workspace, three grippers designed to handle a large variety of different objects in terms of shape, weight and material, and grasp planning in cluttered scenarios. We also present extensive experiments to evaluate the performance of our picking system and demonstrate that the robot is competent to accomplish various tasks in warehouse settings, such as picking a target item from a tight space, grasping different objects from the shelf, and performing pick-and-place tasks on the table.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge