Steve Park

Data-driven development of cycle prediction models for lithium metal batteries using multi modal mining

Nov 26, 2024

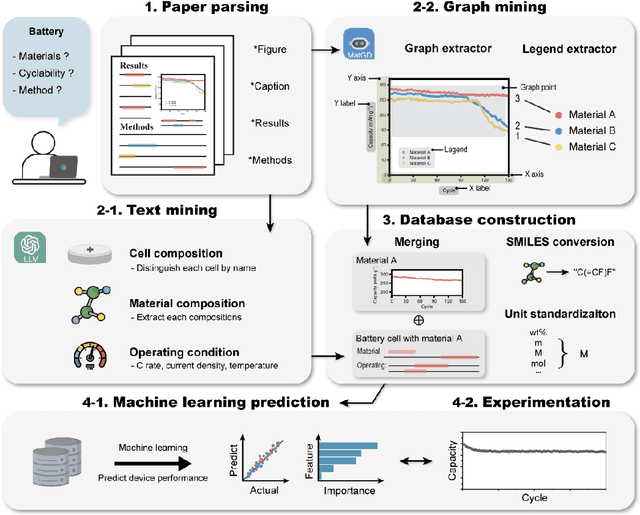

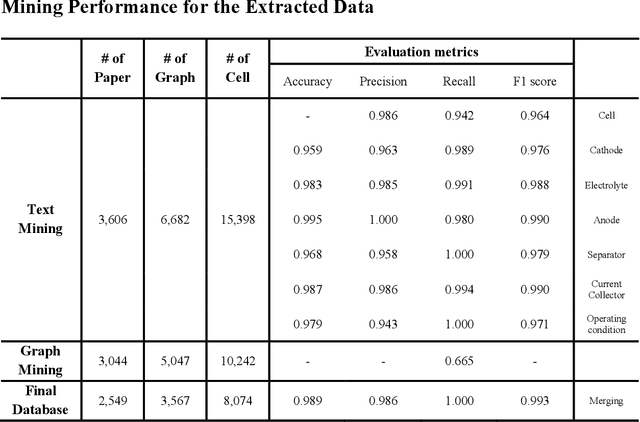

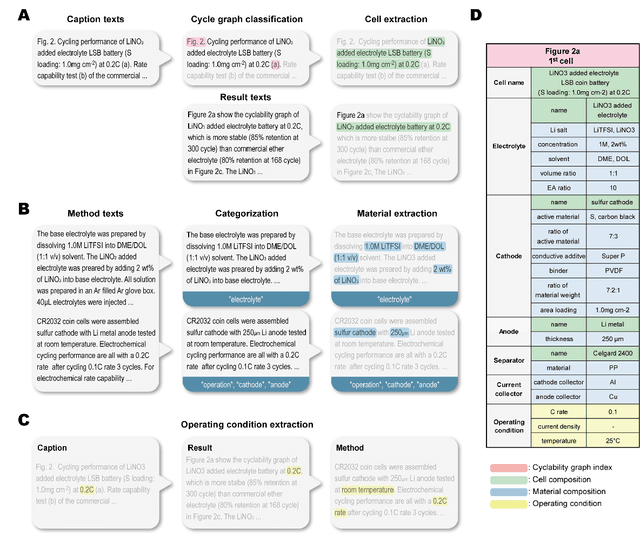

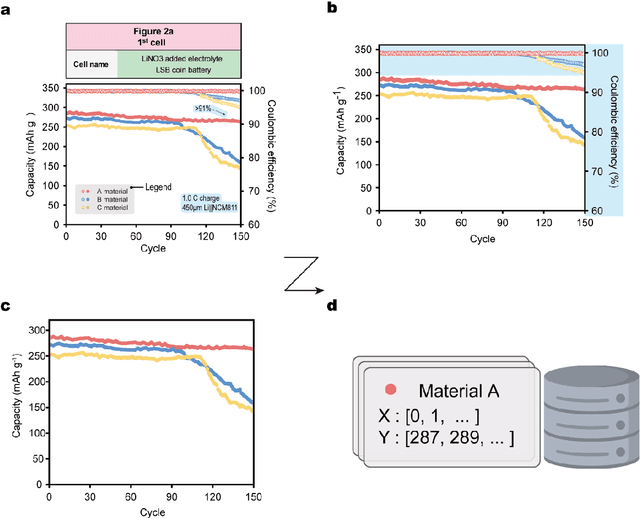

Abstract:Recent advances in data-driven research have shown great potential in understanding the intricate relationships between materials and their performances. Herein, we introduce a novel multi modal data-driven approach employing an Automatic Battery data Collector (ABC) that integrates a large language model (LLM) with an automatic graph mining tool, Material Graph Digitizer (MatGD). This platform enables state-of-the-art accurate extraction of battery material data and cyclability performance metrics from diverse textual and graphical data sources. From the database derived through the ABC platform, we developed machine learning models that can accurately predict the capacity and stability of lithium metal batteries, which is the first-ever model developed to achieve such predictions. Our models were also experimentally validated, confirming practical applicability and reliability of our data-driven approach.

Data-driven Tactile Sensing using Spatially Overlapping Signals

Feb 22, 2018

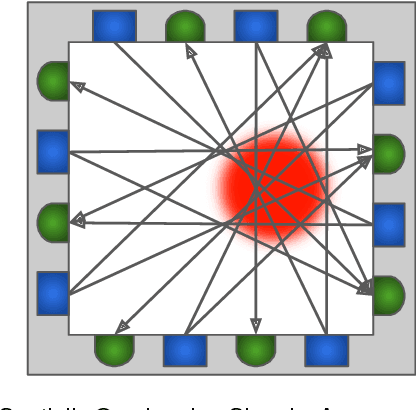

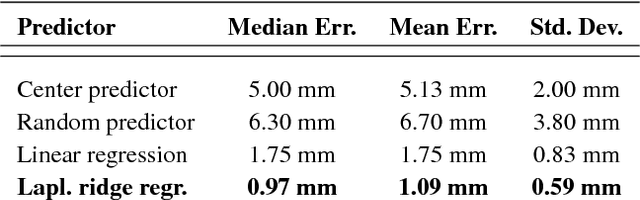

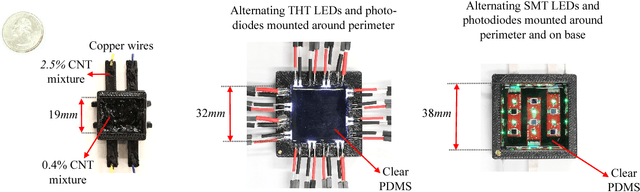

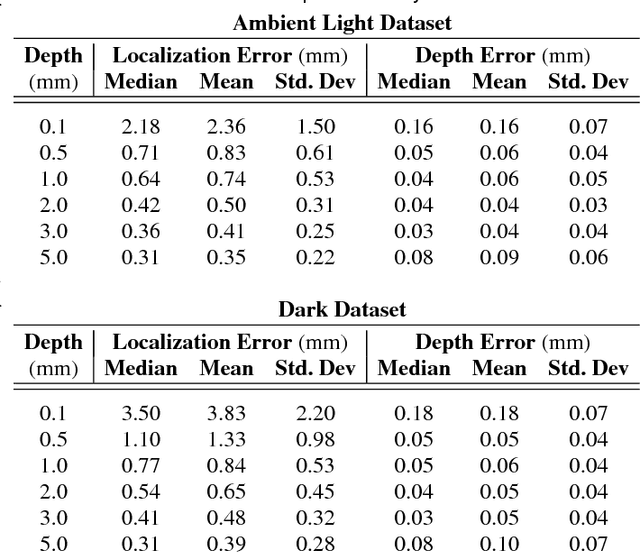

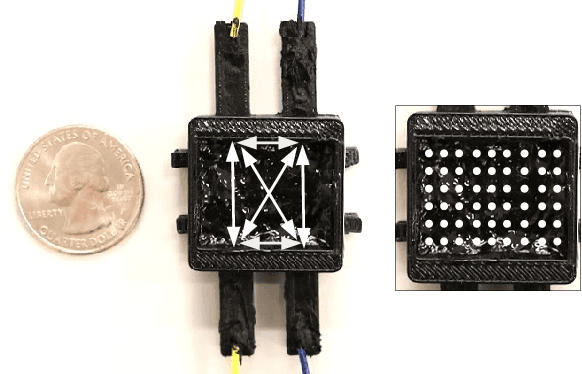

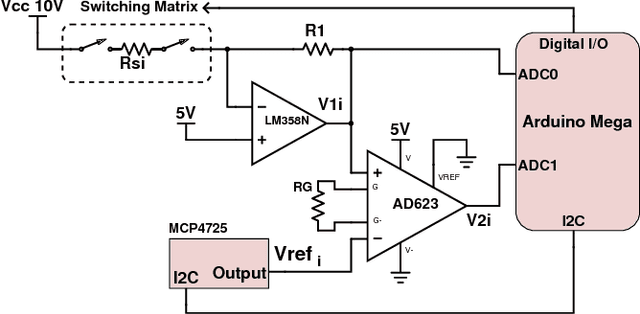

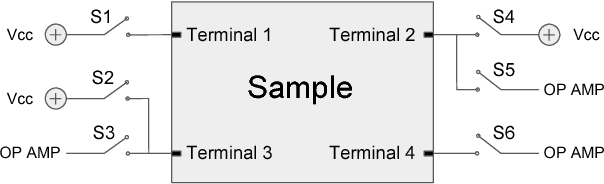

Abstract:Traditional methods for achieving high localization accuracy on tactile sensors usually involve a matrix of miniaturized individual sensors distributed on the area of interest. This approach usually comes at a price of increased complexity in fabrication and circuitry, and can be hard to adapt to non-planar geometries. We propose a method where sensing terminals are embedded in a volume of soft material. Mechanical strain in this material results in a measurable signal between any two given terminals. By having multiple terminals and pairing them against each other in all possible combinations, we obtain a rich signal set using few wires. We mine this data to learn the mapping between the signals we extract and the contact parameters of interest. Our approach is general enough that it can be applied with different transduction methods, and achieves high accuracy in identifying indentation location and depth. Moreover, this method lends itself to simple fabrication techniques and makes no assumption about the underlying geometry, potentially simplifying future integration in robot hands.

Contact Localization through Spatially Overlapping Piezoresistive Signals

Jan 23, 2018

Abstract:Achieving high spatial resolution in contact sensing for robotic manipulation often comes at the price of increased complexity in fabrication and integration. One traditional approach is to fabricate a large number of taxels, each delivering an individual, isolated response to a stimulus. In contrast, we propose a method where the sensor simply consists of a continuous volume of piezoresistive elastomer with a number of electrodes embedded inside. We measure piezoresistive effects between all pairs of electrodes in the set, and count on this rich signal set containing the information needed to pinpoint contact location with high accuracy using regression algorithms. In our validation experiments, we demonstrate submillimeter median accuracy in locating contact on a 10mm by 16mm sensor using only four electrodes (creating six unique pairs). In addition to extracting more information from fewer wires, this approach lends itself to simple fabrication methods and makes no assumptions about the underlying geometry, simplifying future integration on robot fingers.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge