Weipeng Dang

Data-driven Tactile Sensing using Spatially Overlapping Signals

Feb 22, 2018

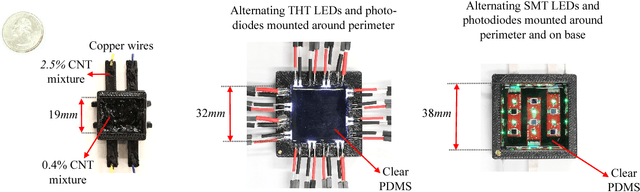

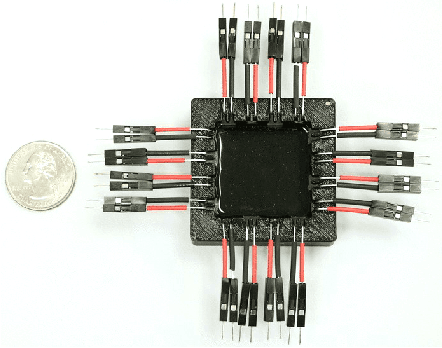

Abstract:Traditional methods for achieving high localization accuracy on tactile sensors usually involve a matrix of miniaturized individual sensors distributed on the area of interest. This approach usually comes at a price of increased complexity in fabrication and circuitry, and can be hard to adapt to non-planar geometries. We propose a method where sensing terminals are embedded in a volume of soft material. Mechanical strain in this material results in a measurable signal between any two given terminals. By having multiple terminals and pairing them against each other in all possible combinations, we obtain a rich signal set using few wires. We mine this data to learn the mapping between the signals we extract and the contact parameters of interest. Our approach is general enough that it can be applied with different transduction methods, and achieves high accuracy in identifying indentation location and depth. Moreover, this method lends itself to simple fabrication techniques and makes no assumption about the underlying geometry, potentially simplifying future integration in robot hands.

Accurate Contact Localization and Indentation Depth Prediction With an Optics-based Tactile Sensor

Feb 19, 2018

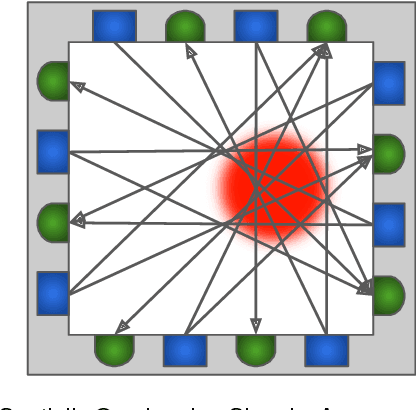

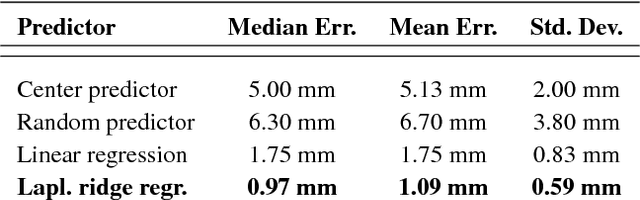

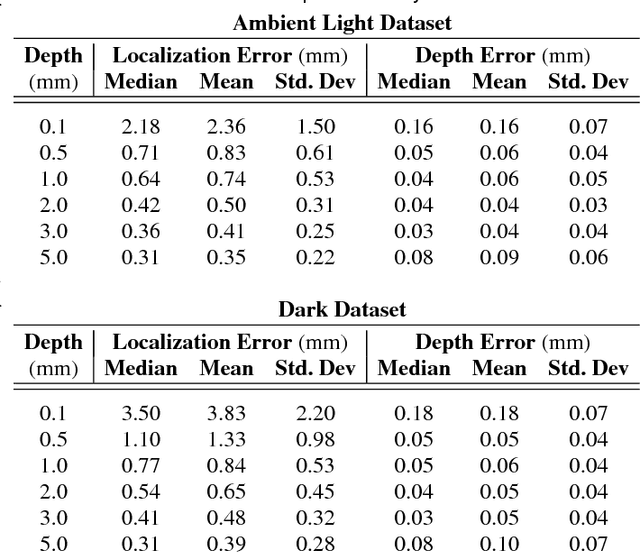

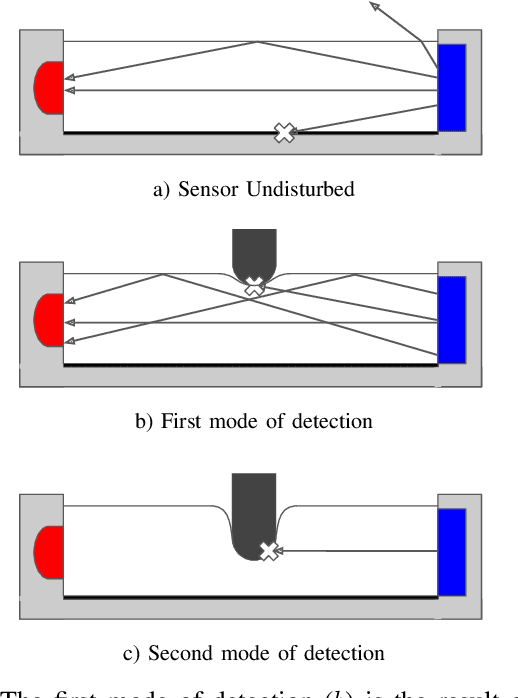

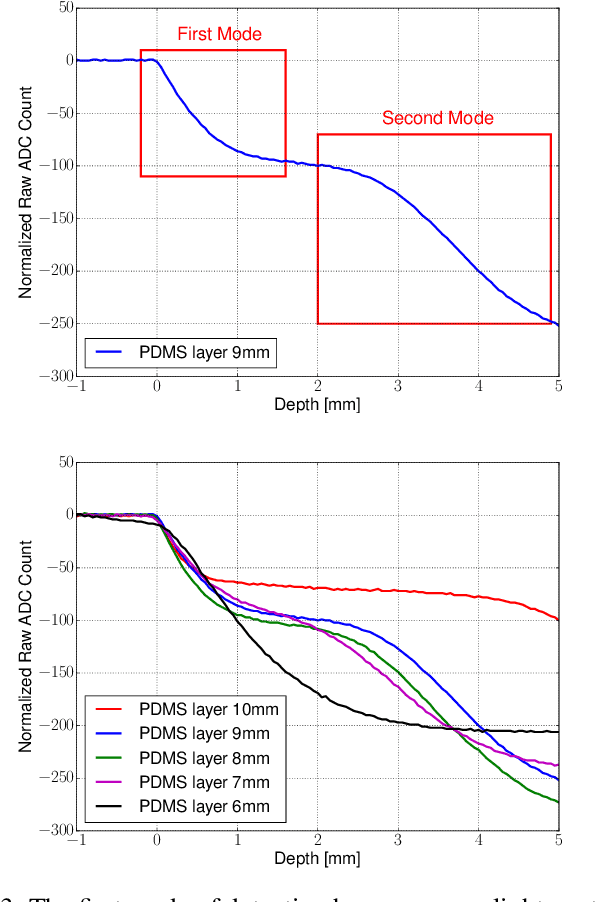

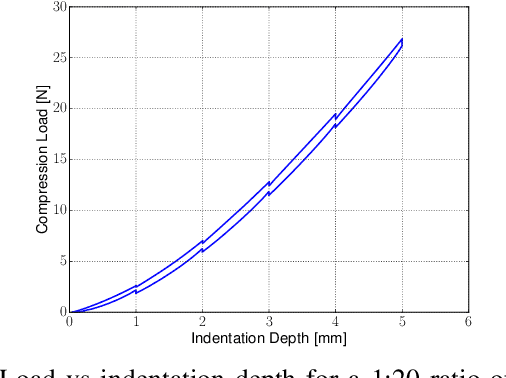

Abstract:Traditional methods to achieve high localization accuracy with tactile sensors usually use a matrix of miniaturized individual sensors distributed on the area of interest. This approach usually comes at a price of increased complexity in fabrication and circuitry, and can be hard to adapt for non planar geometries. We propose to use low cost optic components mounted on the edges of the sensing area to measure how light traveling through an elastomer is affected by touch. Multiple light emitters and receivers provide us with a rich signal set that contains the necessary information to pinpoint both the location and depth of an indentation with high accuracy. We demonstrate sub-millimeter accuracy on location and depth on a 20mm by 20mm active sensing area. Our sensor provides high depth sensitivity as a result of two different modalities in how light is guided through our elastomer. This method results in a low cost, easy to manufacture sensor. We believe this approach can be adapted to cover non-planar surfaces, simplifying future integration in robot skin applications.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge