Saumyadip Mukhopadhyay

An Adversarial Active Sampling-based Data Augmentation Framework for Manufacturable Chip Design

Oct 27, 2022Abstract:Lithography modeling is a crucial problem in chip design to ensure a chip design mask is manufacturable. It requires rigorous simulations of optical and chemical models that are computationally expensive. Recent developments in machine learning have provided alternative solutions in replacing the time-consuming lithography simulations with deep neural networks. However, the considerable accuracy drop still impedes its industrial adoption. Most importantly, the quality and quantity of the training dataset directly affect the model performance. To tackle this problem, we propose a litho-aware data augmentation (LADA) framework to resolve the dilemma of limited data and improve the machine learning model performance. First, we pretrain the neural networks for lithography modeling and a gradient-friendly StyleGAN2 generator. We then perform adversarial active sampling to generate informative and synthetic in-distribution mask designs. These synthetic mask images will augment the original limited training dataset used to finetune the lithography model for improved performance. Experimental results demonstrate that LADA can successfully exploits the neural network capacity by narrowing down the performance gap between the training and testing data instances.

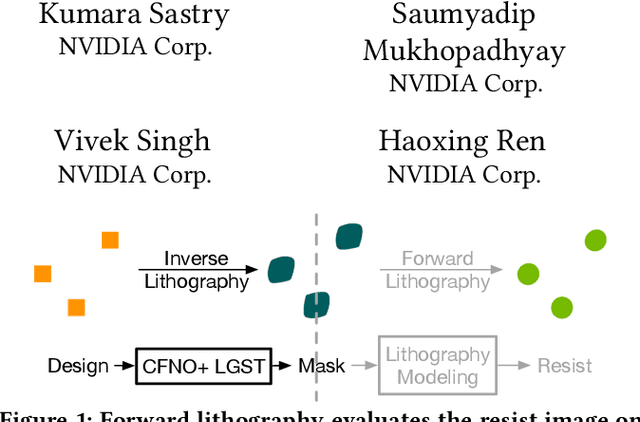

Large Scale Mask Optimization Via Convolutional Fourier Neural Operator and Litho-Guided Self Training

Jul 08, 2022

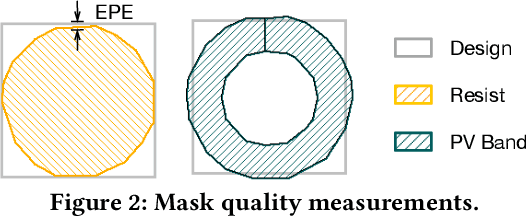

Abstract:Machine learning techniques have been extensively studied for mask optimization problems, aiming at better mask printability, shorter turnaround time, better mask manufacturability, and so on. However, most of these researches are focusing on the initial solution generation of small design regions. To further realize the potential of machine learning techniques on mask optimization tasks, we present a Convolutional Fourier Neural Operator (CFNO) that can efficiently learn layout tile dependencies and hence promise stitch-less large-scale mask optimization with the limited intervention of legacy tools. We discover the possibility of litho-guided self-training (LGST) through a trained machine learning model when solving non-convex optimization problems, which allows iterative model and dataset update and brings significant model performance improvement. Experimental results show that, for the first time, our machine learning-based framework outperforms state-of-the-art academic numerical mask optimizers with an order of magnitude speedup.

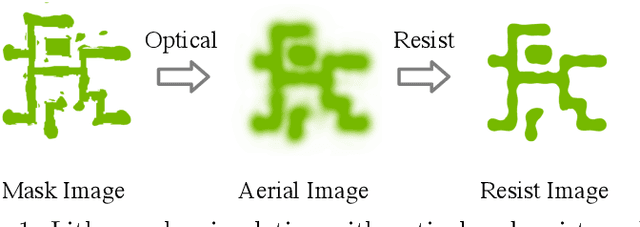

Generic Lithography Modeling with Dual-band Optics-Inspired Neural Networks

Mar 12, 2022

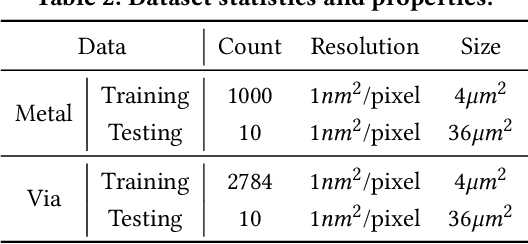

Abstract:Lithography simulation is a critical step in VLSI design and optimization for manufacturability. Existing solutions for highly accurate lithography simulation with rigorous models are computationally expensive and slow, even when equipped with various approximation techniques. Recently, machine learning has provided alternative solutions for lithography simulation tasks such as coarse-grained edge placement error regression and complete contour prediction. However, the impact of these learning-based methods has been limited due to restrictive usage scenarios or low simulation accuracy. To tackle these concerns, we introduce an dual-band optics-inspired neural network design that considers the optical physics underlying lithography. To the best of our knowledge, our approach yields the first published via/metal layer contour simulation at 1nm^2/pixel resolution with any tile size. Compared to previous machine learning based solutions, we demonstrate that our framework can be trained much faster and offers a significant improvement on efficiency and image quality with 20X smaller model size. We also achieve 85X simulation speedup over traditional lithography simulator with 1% accuracy loss.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge