Pascal Egli

ExT: Towards Scalable Autonomous Excavation via Large-Scale Multi-Task Pretraining and Fine-Tuning

Sep 18, 2025

Abstract:Scaling up the deployment of autonomous excavators is of great economic and societal importance. Yet it remains a challenging problem, as effective systems must robustly handle unseen worksite conditions and new hardware configurations. Current state-of-the-art approaches rely on highly engineered, task-specific controllers, which require extensive manual tuning for each new scenario. In contrast, recent advances in large-scale pretrained models have shown remarkable adaptability across tasks and embodiments in domains such as manipulation and navigation, but their applicability to heavy construction machinery remains largely unexplored. In this work, we introduce ExT, a unified open-source framework for large-scale demonstration collection, pretraining, and fine-tuning of multitask excavation policies. ExT policies are first trained on large-scale demonstrations collected from a mix of experts, then fine-tuned either with supervised fine-tuning (SFT) or reinforcement learning fine-tuning (RLFT) to specialize to new tasks or operating conditions. Through both simulation and real-world experiments, we show that pretrained ExT policies can execute complete excavation cycles with centimeter-level accuracy, successfully transferring from simulation to real machine with performance comparable to specialized single-task controllers. Furthermore, in simulation, we demonstrate that ExT's fine-tuning pipelines allow rapid adaptation to new tasks, out-of-distribution conditions, and machine configurations, while maintaining strong performance on previously learned tasks. These results highlight the potential of ExT to serve as a foundation for scalable and generalizable autonomous excavation.

Large Scale Robotic Material Handling: Learning, Planning, and Control

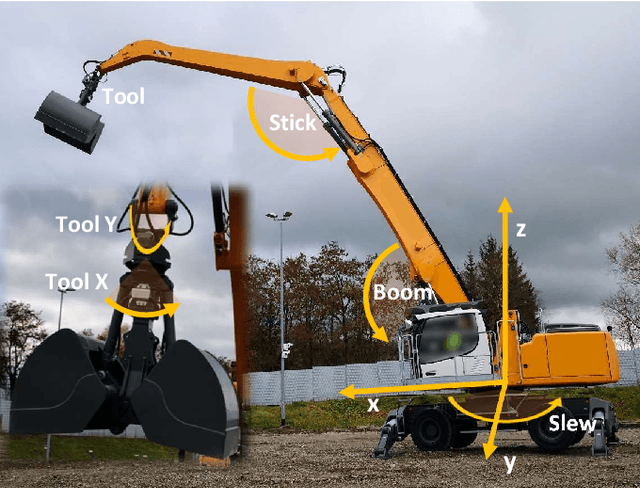

Aug 12, 2025Abstract:Bulk material handling involves the efficient and precise moving of large quantities of materials, a core operation in many industries, including cargo ship unloading, waste sorting, construction, and demolition. These repetitive, labor-intensive, and safety-critical operations are typically performed using large hydraulic material handlers equipped with underactuated grippers. In this work, we present a comprehensive framework for the autonomous execution of large-scale material handling tasks. The system integrates specialized modules for environment perception, pile attack point selection, path planning, and motion control. The main contributions of this work are two reinforcement learning-based modules: an attack point planner that selects optimal grasping locations on the material pile to maximize removal efficiency and minimize the number of scoops, and a robust trajectory following controller that addresses the precision and safety challenges associated with underactuated grippers in movement, while utilizing their free-swinging nature to release material through dynamic throwing. We validate our framework through real-world experiments on a 40 t material handler in a representative worksite, focusing on two key tasks: high-throughput bulk pile management and high-precision truck loading. Comparative evaluations against human operators demonstrate the system's effectiveness in terms of precision, repeatability, and operational safety. To the best of our knowledge, this is the first complete automation of material handling tasks on a full scale.

Reinforcement Learning Control for Autonomous Hydraulic Material Handling Machines with Underactuated Tools

Oct 07, 2024

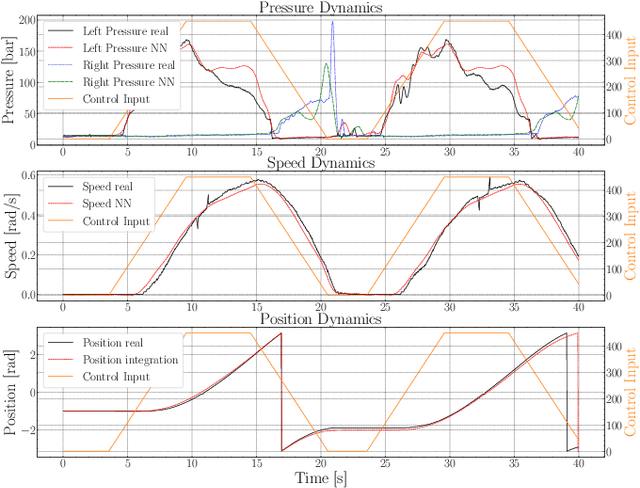

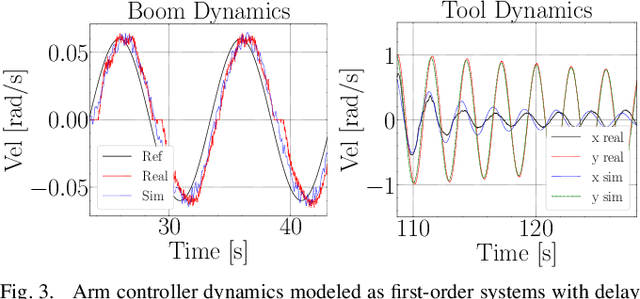

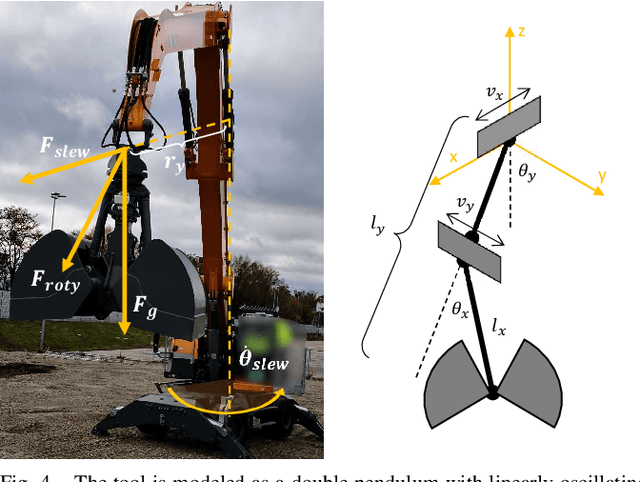

Abstract:The precise and safe control of heavy material handling machines presents numerous challenges due to the hard-to-model hydraulically actuated joints and the need for collision-free trajectory planning with a free-swinging end-effector tool. In this work, we propose an RL-based controller that commands the cabin joint and the arm simultaneously. It is trained in a simulation combining data-driven modeling techniques with first-principles modeling. On the one hand, we employ a neural network model to capture the highly nonlinear dynamics of the upper carriage turn hydraulic motor, incorporating explicit pressure prediction to handle delays better. On the other hand, we model the arm as velocity-controllable and the free-swinging end-effector tool as a damped pendulum using first principles. This combined model enhances our simulation environment, enabling the training of RL controllers that can be directly transferred to the real machine. Designed to reach steady-state Cartesian targets, the RL controller learns to leverage the hydraulic dynamics to improve accuracy, maintain high speeds, and minimize end-effector tool oscillations. Our controller, tested on a mid-size prototype material handler, is more accurate than an inexperienced operator and causes fewer tool oscillations. It demonstrates competitive performance even compared to an experienced professional driver.

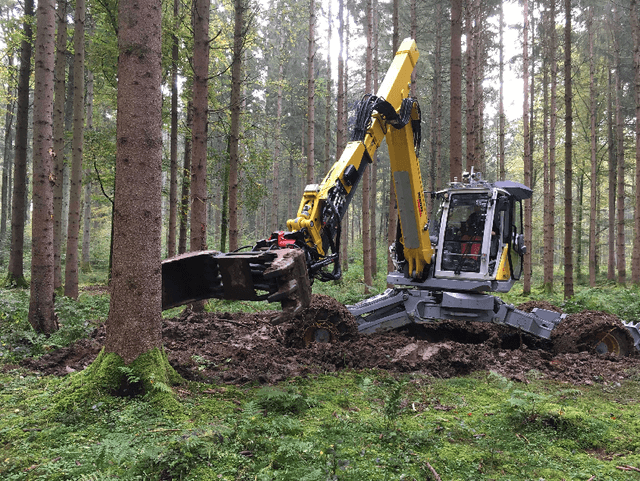

HEAP -- The autonomous walking excavator

Jun 09, 2021

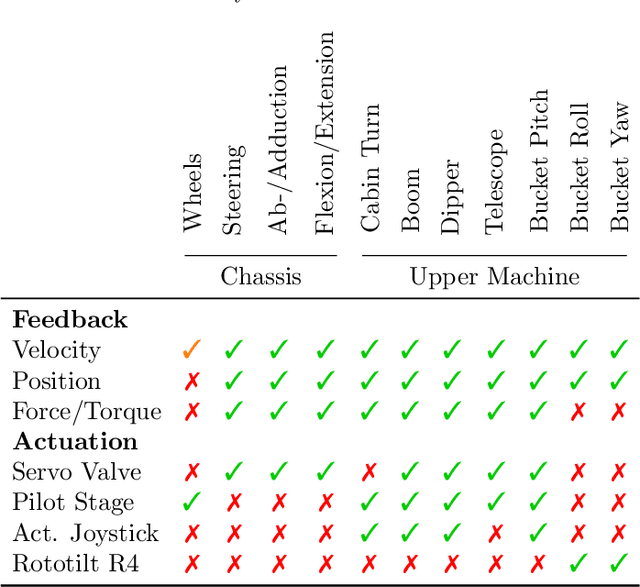

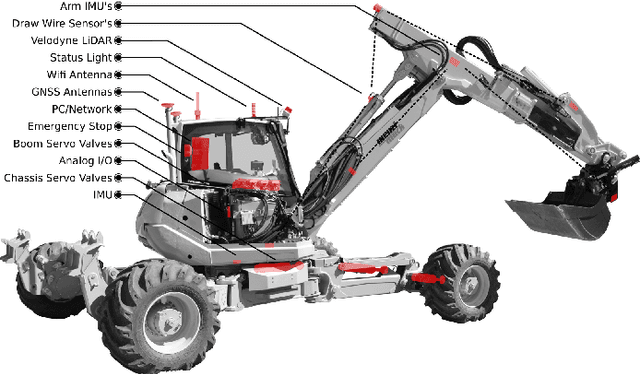

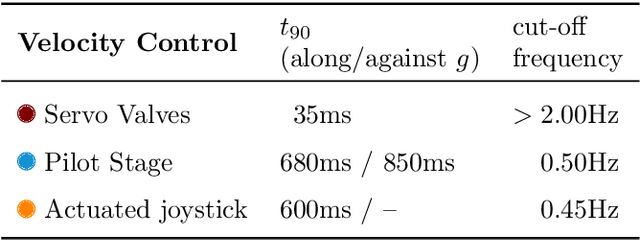

Abstract:The demand and the potential for automation in the construction sector is unmatched, particularly for increasing environmental sustainability, improving worker safety and reducing labor shortages. We have developed an autonomous walking excavator - based one of the most versatile machines found on construction sites - as one way to begin fulfilling this potential. This article describes the process of converting an off-the-shelf construction machine into an autonomous robotic system. First we outline the necessary sensing equipment for full autonomy and the novel actuation of the legs, and compare three different complementary actuation principles for the excavator's arm. Second, we solve the state estimation problem for a general wheeled-legged robot. Beside kinematic measurements, it includes GNSS-RTK, to absolutely reference the machine on a construction site. Third, we developed individual controllers for driving, chassis balancing and arm motions allowing for fully autonomous operation. Lastly, we highlight the machine's potential in four different real-world applications, e.g. autonomous trench digging, autonomous assembly of dry stone walls, autonomous forestry work and semi-autonomous teleoperation. On top, we also share some development insights and possible future research directions.

Towards Autonomous Robotic Precision Harvesting

Apr 20, 2021

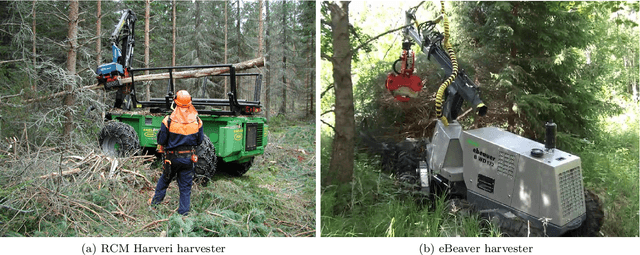

Abstract:This paper presents an integrated system for performing precision harvesting missions using a walking harvester. Our harvester performs the challenging task of autonomous navigation and tree grabbing in a confined, GPS denied forest environment. Strategies for mapping, localization, planning, and control are proposed and integrated into a fully autonomous system. The mission starts with a human or a mobile robot mapping the area of interest using a custom-made sensor module. Subsequently, a human expert or a data-supported algorithm selects the trees for harvesting. The sensor module is then mounted on the machine and used for localization within the given map. A planning algorithm searches for both an approach pose and a path in a single path planning problem. We design a path following controller leveraging the walking harvester's capabilities for negotiating rough terrain. Upon reaching the approach pose, the machine grabs a tree with a general-purpose gripper. This process repeats for all the trees selected by the operator (algorithm). Our system has been tested on a testing field with tree trunks and in a natural forest. To the best of our knowledge, this is the first time this level of autonomy has been shown on a full-size hydraulic machine operating in a realistic environment.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge