Martin Wermelinger

HEAP -- The autonomous walking excavator

Jun 09, 2021

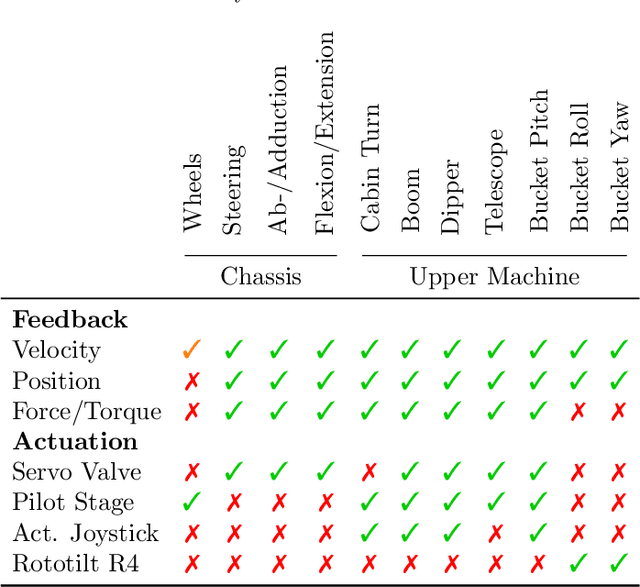

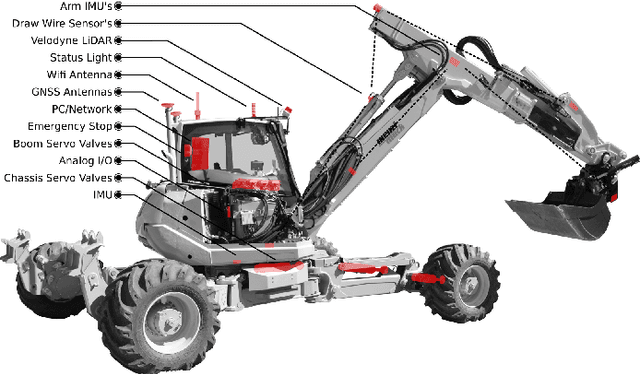

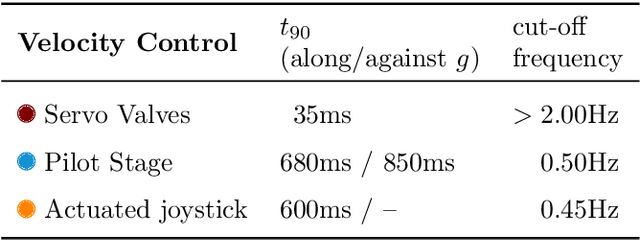

Abstract:The demand and the potential for automation in the construction sector is unmatched, particularly for increasing environmental sustainability, improving worker safety and reducing labor shortages. We have developed an autonomous walking excavator - based one of the most versatile machines found on construction sites - as one way to begin fulfilling this potential. This article describes the process of converting an off-the-shelf construction machine into an autonomous robotic system. First we outline the necessary sensing equipment for full autonomy and the novel actuation of the legs, and compare three different complementary actuation principles for the excavator's arm. Second, we solve the state estimation problem for a general wheeled-legged robot. Beside kinematic measurements, it includes GNSS-RTK, to absolutely reference the machine on a construction site. Third, we developed individual controllers for driving, chassis balancing and arm motions allowing for fully autonomous operation. Lastly, we highlight the machine's potential in four different real-world applications, e.g. autonomous trench digging, autonomous assembly of dry stone walls, autonomous forestry work and semi-autonomous teleoperation. On top, we also share some development insights and possible future research directions.

Contact-Implicit Trajectory Optimization for Dynamic Object Manipulation

Mar 01, 2021

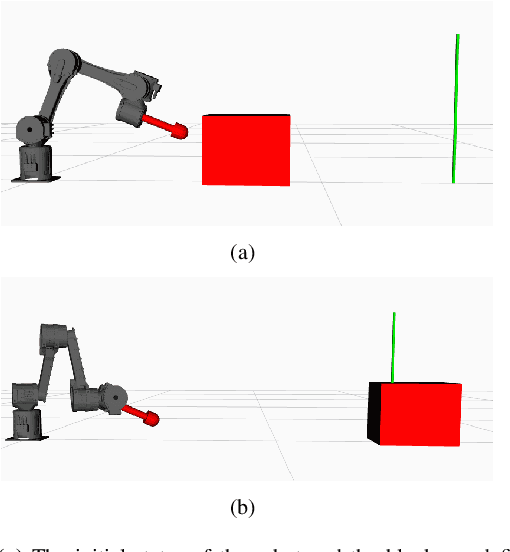

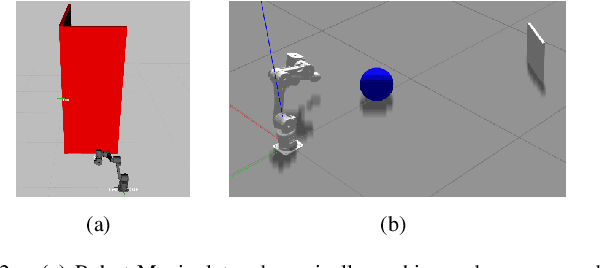

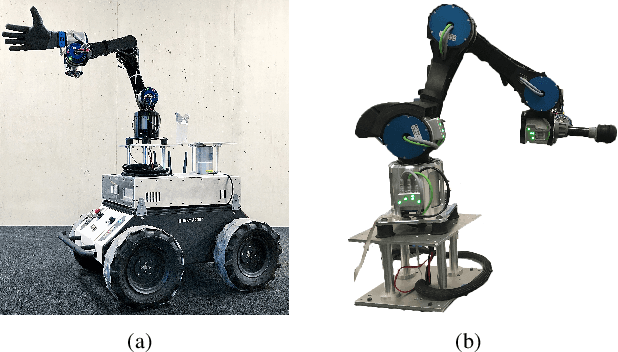

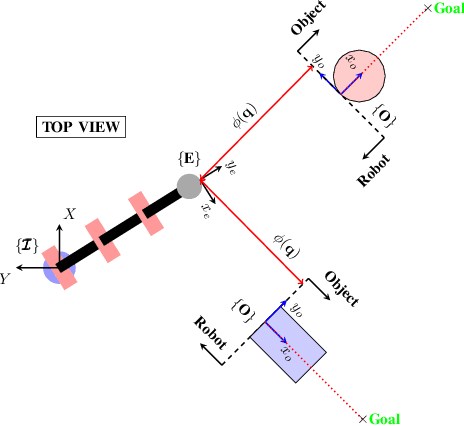

Abstract:We present a reformulation of a contact-implicit optimization (CIO) approach that computes optimal trajectories for rigid-body systems in contact-rich settings. A hard-contact model is assumed, and the unilateral constraints are imposed in the form of complementarity conditions. Newton's impact law is adopted for enhanced physical correctness. The optimal control problem is formulated as a multi-staged program through a multiple-shooting scheme. This problem structure is exploited within the FORCES Pro framework to retrieve optimal motion plans, contact sequences and control inputs with increased computational efficiency. We investigate our method on a variety of dynamic object manipulation tasks, performed by a six degrees of freedom robot. The dynamic feasibility of the optimal trajectories, as well as the repeatability and accuracy of the task-satisfaction are verified through simulations and real hardware experiments on one of the manipulation problems.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge