Patrick Goegler

Reinforcement Learning Control for Autonomous Hydraulic Material Handling Machines with Underactuated Tools

Oct 07, 2024

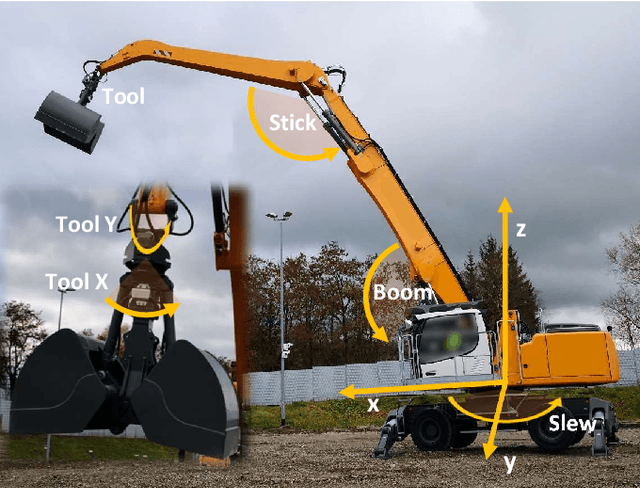

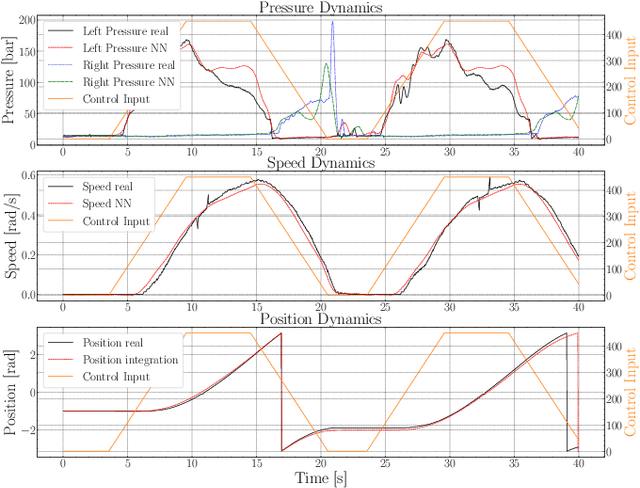

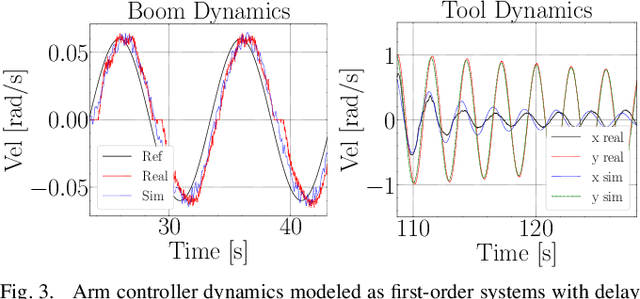

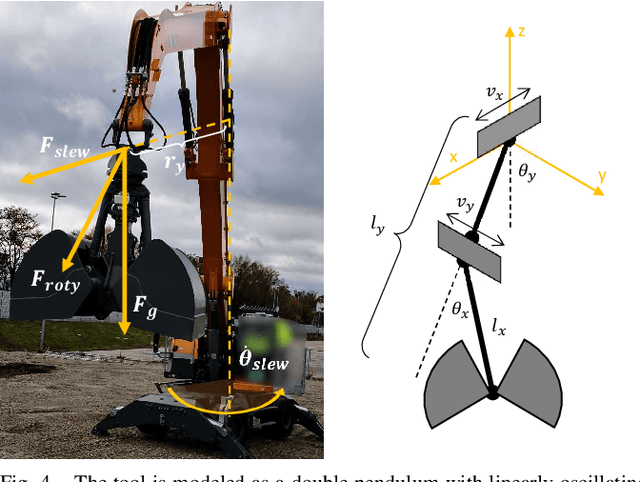

Abstract:The precise and safe control of heavy material handling machines presents numerous challenges due to the hard-to-model hydraulically actuated joints and the need for collision-free trajectory planning with a free-swinging end-effector tool. In this work, we propose an RL-based controller that commands the cabin joint and the arm simultaneously. It is trained in a simulation combining data-driven modeling techniques with first-principles modeling. On the one hand, we employ a neural network model to capture the highly nonlinear dynamics of the upper carriage turn hydraulic motor, incorporating explicit pressure prediction to handle delays better. On the other hand, we model the arm as velocity-controllable and the free-swinging end-effector tool as a damped pendulum using first principles. This combined model enhances our simulation environment, enabling the training of RL controllers that can be directly transferred to the real machine. Designed to reach steady-state Cartesian targets, the RL controller learns to leverage the hydraulic dynamics to improve accuracy, maintain high speeds, and minimize end-effector tool oscillations. Our controller, tested on a mid-size prototype material handler, is more accurate than an inexperienced operator and causes fewer tool oscillations. It demonstrates competitive performance even compared to an experienced professional driver.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge