Mehmet Efe Tiryaki

MRI-powered Magnetic Miniature Capsule Robot with HIFU-controlled On-demand Drug Delivery

Jan 17, 2023

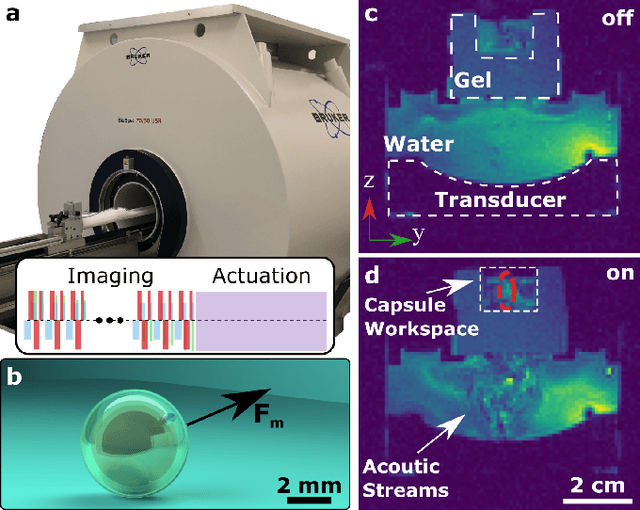

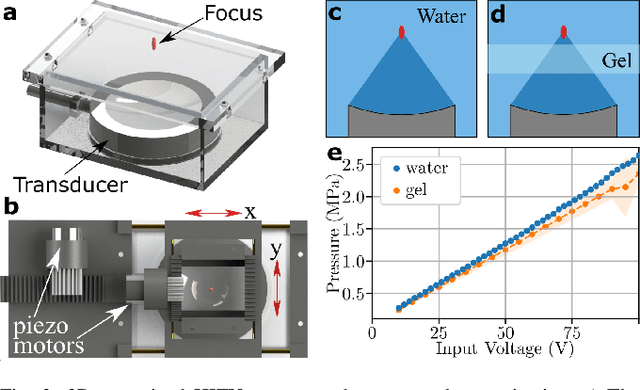

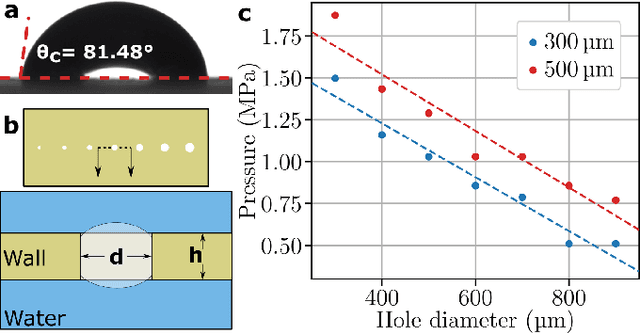

Abstract:Magnetic resonance imaging (MRI)-guided robotic systems offer great potential for new minimally invasive medical tools, including MRI-powered miniature robots. By re-purposing the imaging hardware of an MRI scanner, the magnetic miniature robot could be navigated into the remote part of the patient's body without needing tethered endoscopic tools. However, the state-of-art MRI-powered magnetic miniature robots have limited functionality besides navigation. Here, we propose an MRI-powered magnetic miniature capsule robot benefiting from acoustic streaming forces generated by MRI-guided high-intensity focus ultrasound (HIFU) for controlled drug release. Our design comprises a polymer capsule shell with a submillimeter-diameter drug-release hole that captures an air bubble functioning as a stopper. We use the HIFU pulse to initiate drug release by removing the air bubble once the capsule robot reaches the target location. By controlling acoustic pressure, we also regulate the drug release rate for multiple location targeting during navigation. We demonstrated that the proposed magnetic capsule robot could travel at high speed up to 1.13 cm/s in ex vivo porcine small intestine and release drug to multiple target sites in a single operation, using a combination of MRI-powered actuation and HIFU-controlled release. The proposed MRI-guided microrobotic drug release system will greatly impact minimally invasive medical procedures by allowing on-demand targeted drug delivery.

Aerial Robot Control in Close Proximity to Ceiling: A Force Estimation-based Nonlinear MPC

Jul 31, 2019

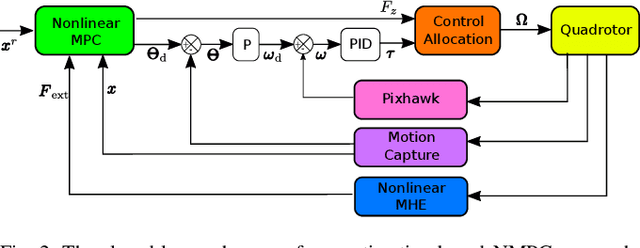

Abstract:Being motivated by ceiling inspection applications via unmanned aerial vehicles (UAVs) which require close proximity flight to surfaces, a systematic control approach enabling safe and accurate close proximity flight is proposed in this work. There are two main challenges for close proximity flights: (i) the trust characteristics varies drastically for the different distance from the ceiling which results in a complex nonlinear dynamics; (ii) the system needs to consider physical and environmental constraints to safely fly in close proximity. To address these challenges, a novel framework consisting of a constrained optimization-based force estimation and an optimization-based nonlinear controller is proposed. Experimental results illustrate that the performance of the proposed control approach can stabilize UAV down to 1 cm distance to the ceiling. Furthermore, we report that the UAV consumes up to 12.5% less power when it is operated 1 cm distance to ceiling, which is promising potential for more battery-efficient inspection flights.

Printing-while-moving: a new paradigm for large-scale robotic 3D Printing

Sep 21, 2018

Abstract:Building and Construction have recently become an exciting application ground for robotics. In particular, rapid progress in materials formulation and in robotics technology has made robotic 3D Printing of concrete a promising technique for in-situ construction. Yet, scalability remains an important hurdle to widespread adoption: the printing systems (gantry- based or arm-based) are often much larger than the structure to be printed, hence cumbersome. Recently, a mobile printing system - a manipulator mounted on a mobile base - was proposed to alleviate this issue: such a system, by moving its base, can potentially print a structure larger than itself. However, the proposed system could only print while being stationary, imposing thereby a limit on the size of structures that can be printed in a single take. Here, we develop a system that implements the printing-while-moving paradigm, which enables printing single-piece structures of arbitrary sizes with a single robot. This development requires solving motion planning, localization, and motion control problems that are specific to mobile 3D Printing. We report our framework to address those problems, and demonstrate, for the first time, a printing-while-moving experiment, wherein a 210 cm x 45 cm x 10 cm concrete structure is printed by a robot arm that has a reach of 87 cm.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge