Kewei Song

Cyborg Insect Factory: Automatic Assembly System to Build up Insect-computer Hybrid Robot Based on Vision-guided Robotic Arm Manipulation of Custom Bipolar Electrodes

Nov 20, 2024Abstract:The advancement of insect-computer hybrid robots holds significant promise for navigating complex terrains and enhancing robotics applications. This study introduced an automatic assembly method for insect-computer hybrid robots, which was accomplished by mounting backpack with precise implantation of custom-designed bipolar electrodes. We developed a stimulation protocol for the intersegmental membrane between pronotum and mesothorax of the Madagascar hissing cockroach, allowing for bipolar electrodes' automatic implantation using a robotic arm. The assembly process was integrated with a deep learning-based vision system to accurately identify the implantation site, and a dedicated structure to fix the insect (68 s for the whole assembly process). The automatically assembled hybrid robots demonstrated steering control (over 70 degrees for 0.4 s stimulation) and deceleration control (68.2% speed reduction for 0.4 s stimulation), matching the performance of manually assembled systems. Furthermore, a multi-agent system consisting of 4 hybrid robots successfully covered obstructed outdoor terrain (80.25% for 10 minutes 31 seconds), highlighting the feasibility of mass-producing these systems for practical applications. The proposed automatic assembly strategy reduced preparation time for the insect-computer hybrid robots while maintaining their precise control, laying a foundation for scalable production and deployment in real-world applications.

3D Programming of Patterned Heterogeneous Interface for 4D Smart Robotics

Dec 22, 2023Abstract:Shape memory structures are playing an important role in many cutting-edge intelligent fields. However, the existing technologies can only realize 4D printing of a single polymer or metal, which limits practical applications. Here, we report a construction strategy for TSMP/M heterointerface, which uses Pd2+-containing shape memory polymer (AP-SMR) to induce electroless plating reaction and relies on molecular dynamics, which has both shape memory properties and metal activity and information processing power. Through multi-material DLP 3D printing technology, the interface can be 3D selectively programmed on functional substrate parts of arbitrary shapes to become 4D electronic smart devices (Robotics). Microscopically, this type of interface appears as a composite structure with a nanometer-micrometer interface height, which is composed of a pure substrate layer (smart materials), an intermediate layer (a composite structure in which metal particles are embedded in a polymer cross-linked network) and a pure metal layer. The structure programmed by TSMP/M heterointerface exhibits both SMA characteristics and metal properties, thus having more intelligent functions (electroactive, electrothermal deformation, electronically controlled denaturation) and higher performance (selectivity of shape memory structures can be realized control, remote control, inline control and low voltage control). This is expected to provide a more flexible manufacturing process as platform technology for designing, manufacturing and applying smart devices with new concepts, and promote the development of cutting-edge industries such as smart robots and smart electronics.

New metal-plastic hybrid additive manufacturing strategy: Fabrication of arbitrary metal-patterns on external and even internal surfaces of 3D plastic structures

Dec 22, 2021

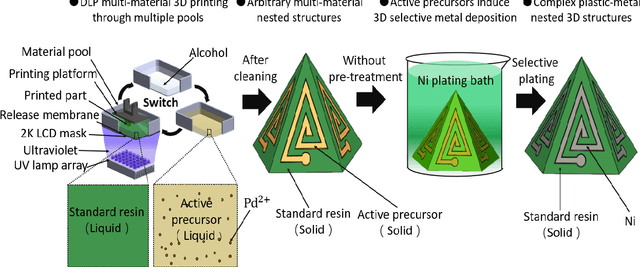

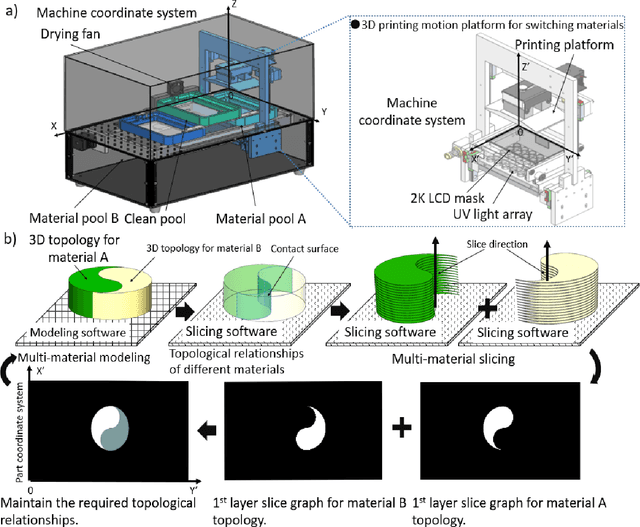

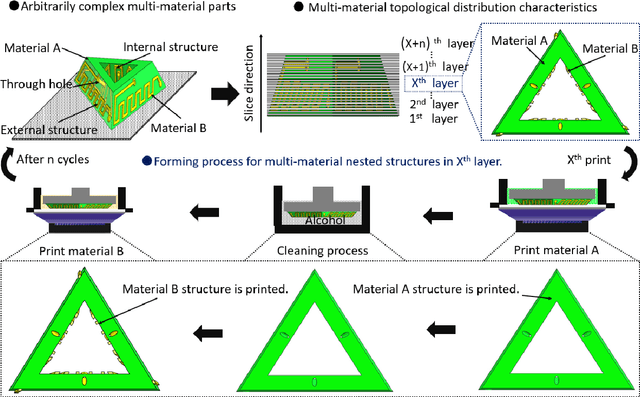

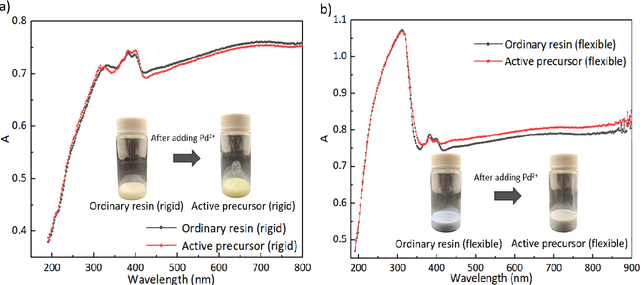

Abstract:Constructing precise micro-nano metal patterns on complex three-dimensional (3D) plastic parts allows the fabrication of functional devices for advanced applications. However, this patterning is currently expensive and requires complex processes with long manufacturing lead time. The present work demonstrates a process for the fabrication of micro-nano 3D metal-plastic composite structures with arbitrarily complex shapes. In this approach, a light-cured resin is modified to prepare an active precursor capable of allowing subsequent electroless plating (ELP). A multi-material digital light processing 3D printer was newly developed to enable the fabrication of parts containing regions made of either standard resin or active precursor resin nested within each other. Selective 3D ELP processing of such parts provided various metal-plastic composite parts having complicated hollow micro-nano structures with specific topological relationships on a size scale as small as 40 um. Using this technique, 3D metal topologies that cannot be manufactured by traditional methods are possible, and metal patterns can be produced inside plastic parts as a means of further miniaturizing electronic devices. The proposed method can also generate metal coatings exhibiting improved adhesion of metal to plastic substrate. Based on this technique, several sensors composed of different functional nonmetallic materials and specific metal patterns were designed and fabricated. The present results demonstrate the viability of the proposed method and suggest potential applications in the fields of smart 3D micro-nano electronics, 3D wearable devices, micro/nano-sensors, and health care.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge