New metal-plastic hybrid additive manufacturing strategy: Fabrication of arbitrary metal-patterns on external and even internal surfaces of 3D plastic structures

Paper and Code

Dec 22, 2021

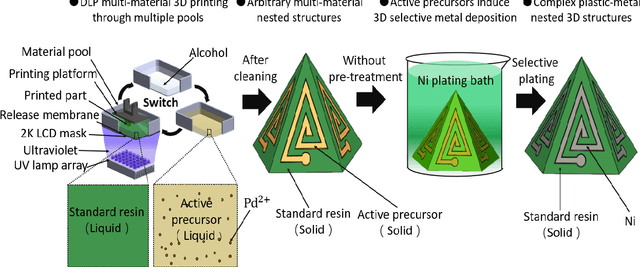

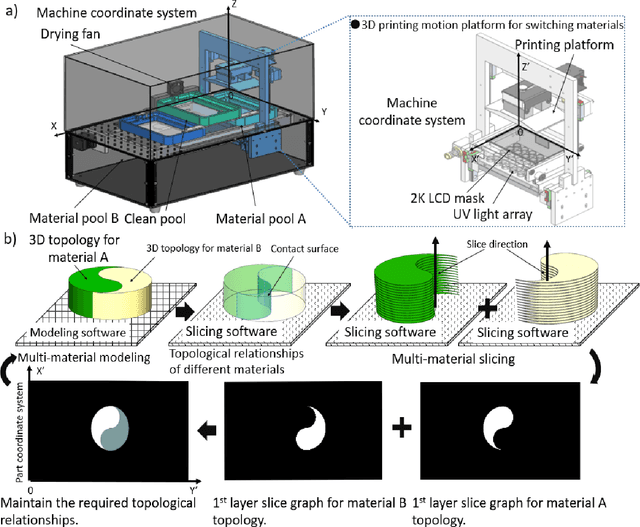

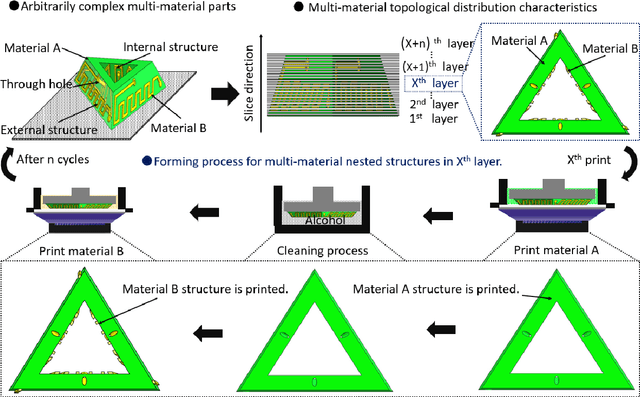

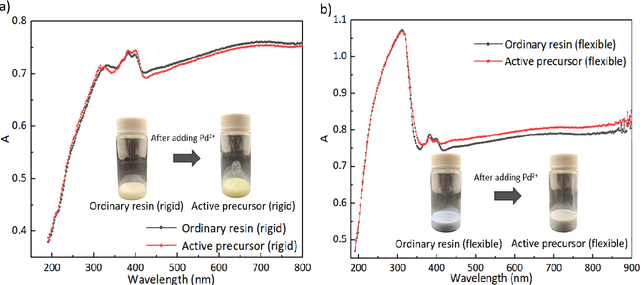

Constructing precise micro-nano metal patterns on complex three-dimensional (3D) plastic parts allows the fabrication of functional devices for advanced applications. However, this patterning is currently expensive and requires complex processes with long manufacturing lead time. The present work demonstrates a process for the fabrication of micro-nano 3D metal-plastic composite structures with arbitrarily complex shapes. In this approach, a light-cured resin is modified to prepare an active precursor capable of allowing subsequent electroless plating (ELP). A multi-material digital light processing 3D printer was newly developed to enable the fabrication of parts containing regions made of either standard resin or active precursor resin nested within each other. Selective 3D ELP processing of such parts provided various metal-plastic composite parts having complicated hollow micro-nano structures with specific topological relationships on a size scale as small as 40 um. Using this technique, 3D metal topologies that cannot be manufactured by traditional methods are possible, and metal patterns can be produced inside plastic parts as a means of further miniaturizing electronic devices. The proposed method can also generate metal coatings exhibiting improved adhesion of metal to plastic substrate. Based on this technique, several sensors composed of different functional nonmetallic materials and specific metal patterns were designed and fabricated. The present results demonstrate the viability of the proposed method and suggest potential applications in the fields of smart 3D micro-nano electronics, 3D wearable devices, micro/nano-sensors, and health care.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge