Jiafu Wan

Artificial Intelligence-Driven Customized Manufacturing Factory: Key Technologies, Applications, and Challenges

Aug 07, 2021

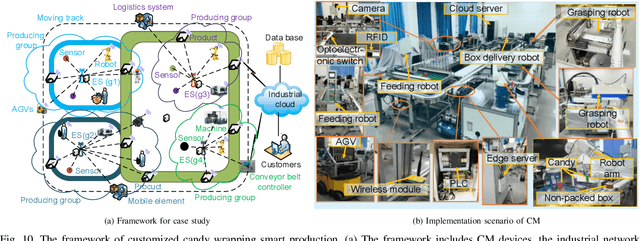

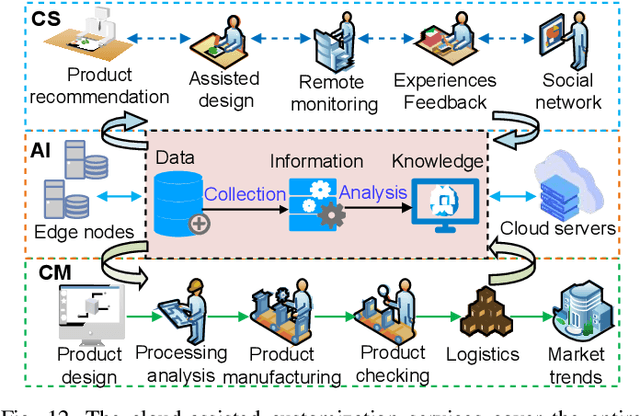

Abstract:The traditional production paradigm of large batch production does not offer flexibility towards satisfying the requirements of individual customers. A new generation of smart factories is expected to support new multi-variety and small-batch customized production modes. For that, Artificial Intelligence (AI) is enabling higher value-added manufacturing by accelerating the integration of manufacturing and information communication technologies, including computing, communication, and control. The characteristics of a customized smart factory are to include self-perception, operations optimization, dynamic reconfiguration, and intelligent decision-making. The AI technologies will allow manufacturing systems to perceive the environment, adapt to the external needs, and extract the process knowledge, including business models, such as intelligent production, networked collaboration, and extended service models. This paper focuses on the implementation of AI in customized manufacturing (CM). The architecture of an AI-driven customized smart factory is presented. Details of intelligent manufacturing devices, intelligent information interaction, and construction of a flexible manufacturing line are showcased. The state-of-the-art AI technologies of potential use in CM, i.e., machine learning, multi-agent systems, Internet of Things, big data, and cloud-edge computing are surveyed. The AI-enabled technologies in a customized smart factory are validated with a case study of customized packaging. The experimental results have demonstrated that the AI-assisted CM offers the possibility of higher production flexibility and efficiency. Challenges and solutions related to AI in CM are also discussed.

* 21 pages, 12 figures

Resource Allocation and Service Provisioning in Multi-Agent Cloud Robotics: A Comprehensive Survey

Apr 29, 2021

Abstract:Robotic applications nowadays are widely adopted to enhance operational automation and performance of real-world Cyber-Physical Systems (CPSs) including Industry 4.0, agriculture, healthcare, and disaster management. These applications are composed of latency-sensitive, data-heavy, and compute-intensive tasks. The robots, however, are constrained in the computational power and storage capacity. The concept of multi-agent cloud robotics enables robot-to-robot cooperation and creates a complementary environment for the robots in executing large-scale applications with the capability to utilize the edge and cloud resources. However, in such a collaborative environment, the optimal resource allocation for robotic tasks is challenging to achieve. Heterogeneous energy consumption rates and application of execution costs associated with the robots and computing instances make it even more complex. In addition, the data transmission delay between local robots, edge nodes, and cloud data centres adversely affects the real-time interactions and impedes service performance guarantee. Taking all these issues into account, this paper comprehensively surveys the state-of-the-art on resource allocation and service provisioning in multi-agent cloud robotics. The paper presents the application domains of multi-agent cloud robotics through explicit comparison with the contemporary computing paradigms and identifies the specific research challenges. A complete taxonomy on resource allocation is presented for the first time, together with the discussion of resource pooling, computation offloading, and task scheduling for efficient service provisioning. Furthermore, we highlight the research gaps from the learned lessons, and present future directions deemed beneficial to further advance this emerging field.

Big Data Analytics for Manufacturing Internet of Things: Opportunities, Challenges and Enabling Technologies

Sep 01, 2019

Abstract:The recent advances in information and communication technology (ICT) have promoted the evolution of conventional computer-aided manufacturing industry to smart data-driven manufacturing. Data analytics in massive manufacturing data can extract huge business values while can also result in research challenges due to the heterogeneous data types, enormous volume and real-time velocity of manufacturing data. This paper provides an overview on big data analytics in manufacturing Internet of Things (MIoT). This paper first starts with a discussion on necessities and challenges of big data analytics in manufacturing data of MIoT. Then, the enabling technologies of big data analytics of manufacturing data are surveyed and discussed. Moreover, this paper also outlines the future directions in this promising area.

* 14 pages, 6 figures, 3 tables

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge