Jannis Walk

Artificial Intelligence for Sustainability: Facilitating Sustainable Smart Product-Service Systems with Computer Vision

Mar 27, 2023

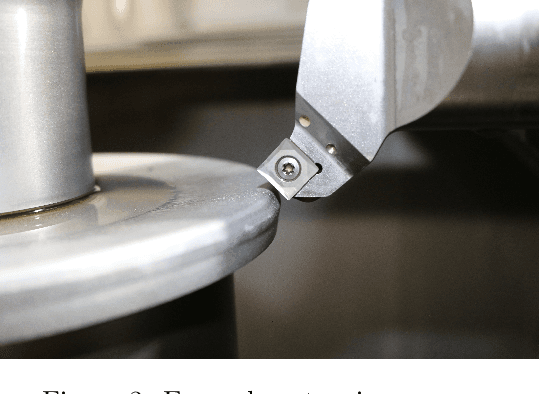

Abstract:The usage and impact of deep learning for cleaner production and sustainability purposes remain little explored. This work shows how deep learning can be harnessed to increase sustainability in production and product usage. Specifically, we utilize deep learning-based computer vision to determine the wear states of products. The resulting insights serve as a basis for novel product-service systems with improved integration and result orientation. Moreover, these insights are expected to facilitate product usage improvements and R&D innovations. We demonstrate our approach on two products: machining tools and rotating X-ray anodes. From a technical standpoint, we show that it is possible to recognize the wear state of these products using deep-learning-based computer vision. In particular, we detect wear through microscopic images of the two products. We utilize a U-Net for semantic segmentation to detect wear based on pixel granularity. The resulting mean dice coefficients of 0.631 and 0.603 demonstrate the feasibility of the proposed approach. Consequently, experts can now make better decisions, for example, to improve the machining process parameters. To assess the impact of the proposed approach on environmental sustainability, we perform life cycle assessments that show gains for both products. The results indicate that the emissions of CO2 equivalents are reduced by 12% for machining tools and by 44% for rotating anodes. This work can serve as a guideline and inspire researchers and practitioners to utilize computer vision in similar scenarios to develop sustainable smart product-service systems and enable cleaner production.

Data-centric Artificial Intelligence

Dec 22, 2022

Abstract:Data-centric artificial intelligence (data-centric AI) represents an emerging paradigm emphasizing that the systematic design and engineering of data is essential for building effective and efficient AI-based systems. The objective of this article is to introduce practitioners and researchers from the field of Information Systems (IS) to data-centric AI. We define relevant terms, provide key characteristics to contrast the data-centric paradigm to the model-centric one, and introduce a framework for data-centric AI. We distinguish data-centric AI from related concepts and discuss its longer-term implications for the IS community.

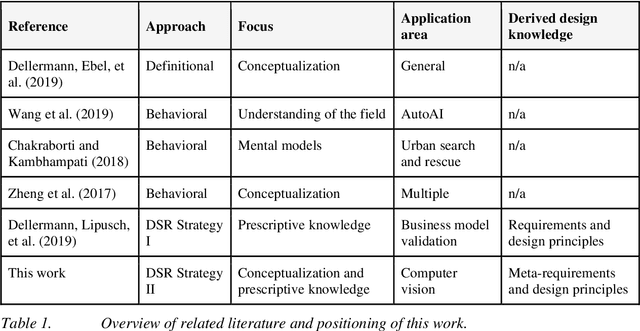

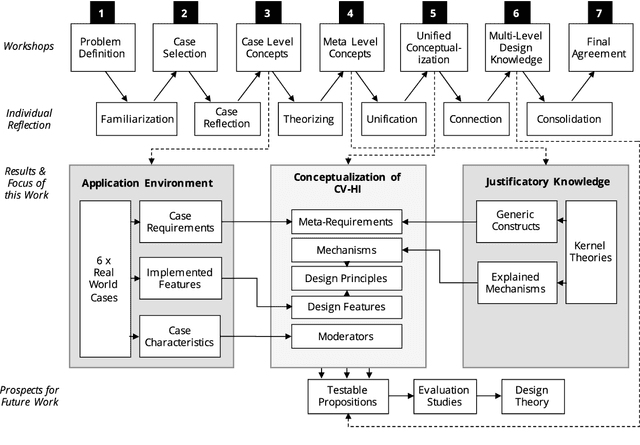

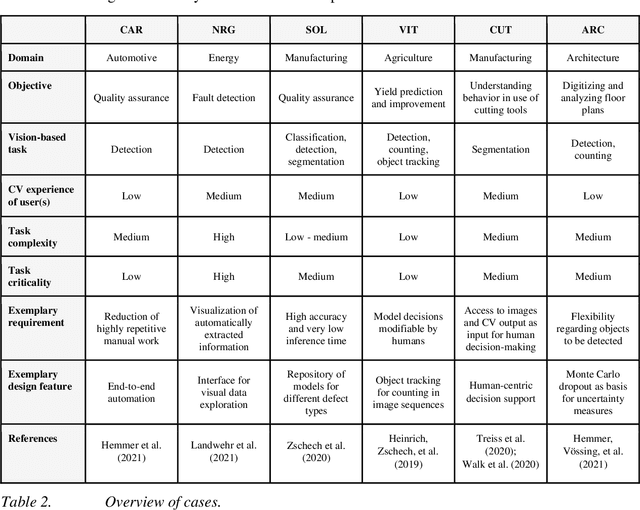

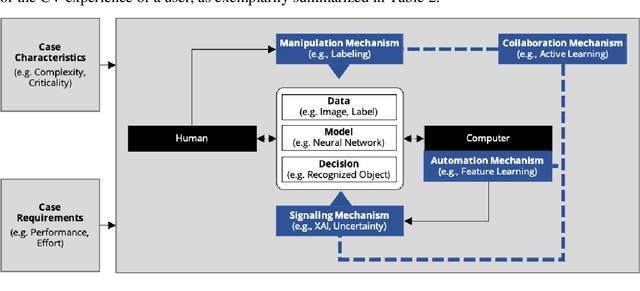

A Picture is Worth a Collaboration: Accumulating Design Knowledge for Computer-Vision-based Hybrid Intelligence Systems

Apr 23, 2021

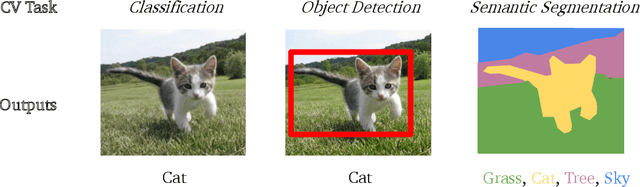

Abstract:Computer vision (CV) techniques try to mimic human capabilities of visual perception to support labor-intensive and time-consuming tasks like the recognition and localization of critical objects. Nowadays, CV increasingly relies on artificial intelligence (AI) to automatically extract useful information from images that can be utilized for decision support and business process automation. However, the focus of extant research is often exclusively on technical aspects when designing AI-based CV systems while neglecting socio-technical facets, such as trust, control, and autonomy. For this purpose, we consider the design of such systems from a hybrid intelligence (HI) perspective and aim to derive prescriptive design knowledge for CV-based HI systems. We apply a reflective, practice-inspired design science approach and accumulate design knowledge from six comprehensive CV projects. As a result, we identify four design-related mechanisms (i.e., automation, signaling, modification, and collaboration) that inform our derived meta-requirements and design principles. This can serve as a basis for further socio-technical research on CV-based HI systems.

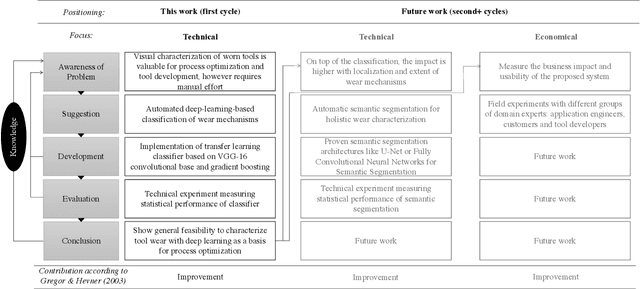

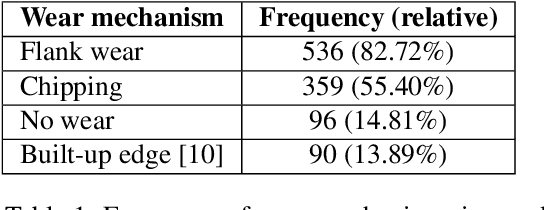

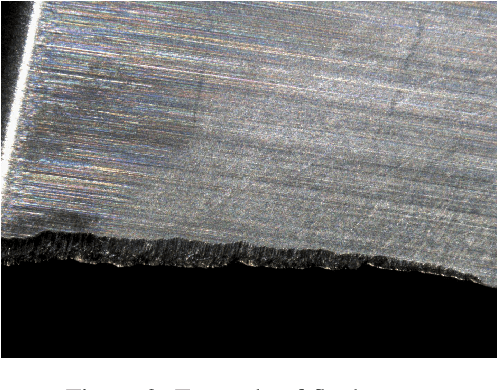

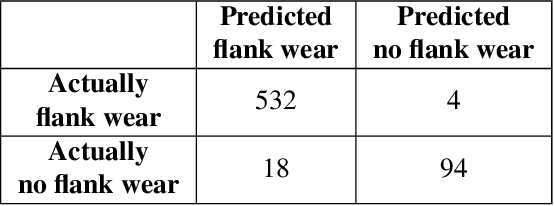

Towards Leveraging End-of-Life Tools as an Asset: Value Co-Creation based on Deep Learning in the Machining Industry

Jul 24, 2020

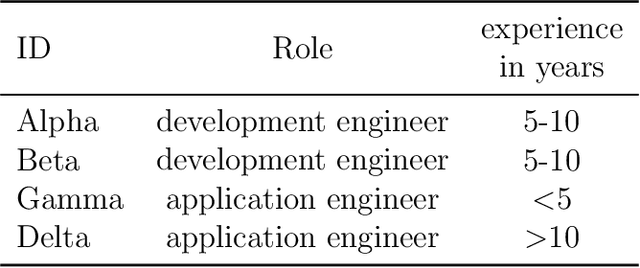

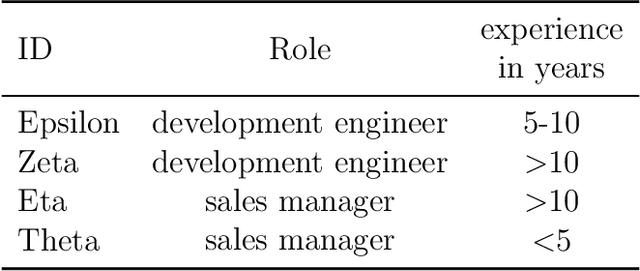

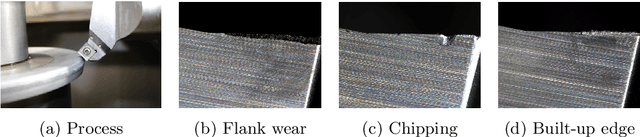

Abstract:Sustainability is the key concept in the management of products that reached their end-of-life. We propose that end-of-life products have -- besides their value as recyclable assets -- additional value for producer and consumer. We argue this is especially true for the machining industry, where we illustrate an automatic characterization of worn cutting tools to foster value co-creation between tool manufacturer and tool user (customer) in the future. In the work at hand, we present a deep-learning-based computer vision system for the automatic classification of worn tools regarding flank wear and chipping. The resulting Matthews Correlation Coefficient of 0.878 and 0.644 confirms the feasibility of our system based on the VGG-16 network and Gradient Boosting. Based on these first results we derive a research agenda which addresses the need for a more holistic tool characterization by semantic segmentation and assesses the perceived business impact and usability by different user groups.

An Uncertainty-based Human-in-the-loop System for Industrial Tool Wear Analysis

Jul 16, 2020

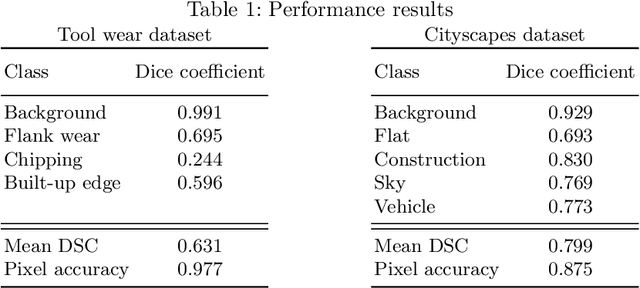

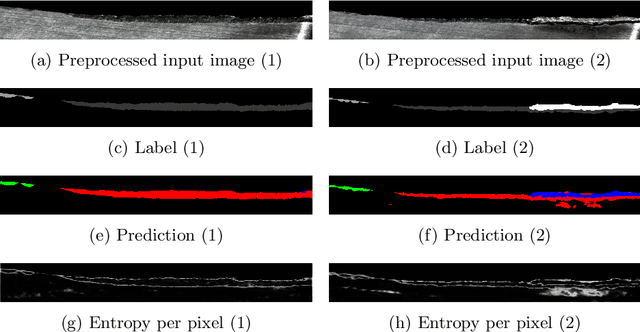

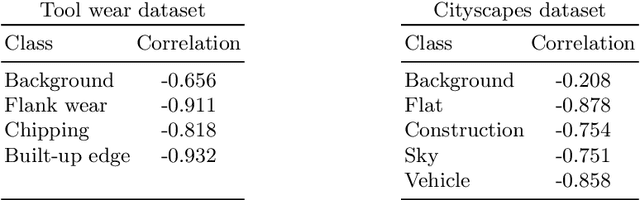

Abstract:Convolutional neural networks have shown to achieve superior performance on image segmentation tasks. However, convolutional neural networks, operating as black-box systems, generally do not provide a reliable measure about the confidence of their decisions. This leads to various problems in industrial settings, amongst others, inadequate levels of trust from users in the model's outputs as well as a non-compliance with current policy guidelines (e.g., EU AI Strategy). To address these issues, we use uncertainty measures based on Monte-Carlo dropout in the context of a human-in-the-loop system to increase the system's transparency and performance. In particular, we demonstrate the benefits described above on a real-world multi-class image segmentation task of wear analysis in the machining industry. Following previous work, we show that the quality of a prediction correlates with the model's uncertainty. Additionally, we demonstrate that a multiple linear regression using the model's uncertainties as independent variables significantly explains the quality of a prediction (\(R^2=0.718\)). Within the uncertainty-based human-in-the-loop system, the multiple regression aims at identifying failed predictions on an image-level. The system utilizes a human expert to label these failed predictions manually. A simulation study demonstrates that the uncertainty-based human-in-the-loop system increases performance for different levels of human involvement in comparison to a random-based human-in-the-loop system. To ensure generalizability, we show that the presented approach achieves similar results on the publicly available Cityscapes dataset.

Half-empty or half-full? A Hybrid Approach to Predict Recycling Behavior of Consumers to Increase Reverse Vending Machine Uptime

Mar 30, 2020

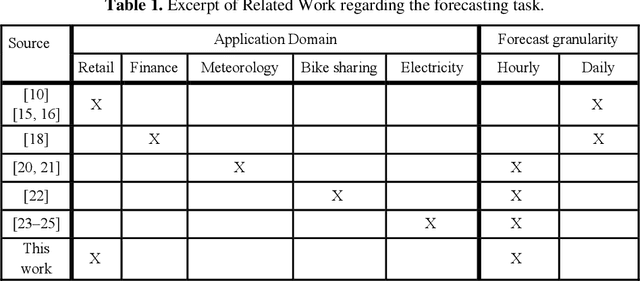

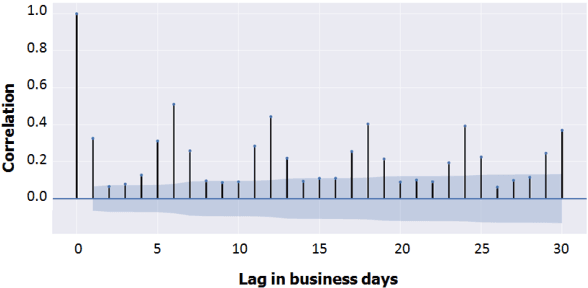

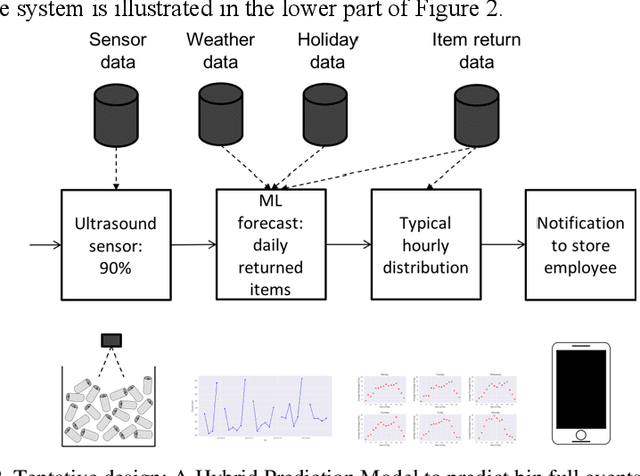

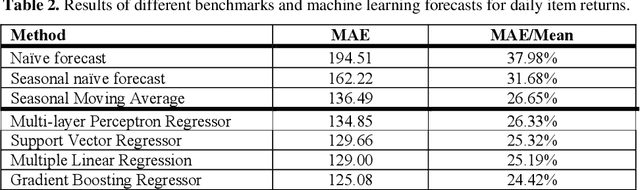

Abstract:Reverse Vending Machines (RVMs) are a proven instrument for facilitating closed-loop plastic packaging recycling. A good customer experience at the RVM is crucial for a further proliferation of this technology. Bin full events are the major reason for Reverse Vending Machine (RVM) downtime at the world leader in the RVM market. The paper at hand develops and evaluates an approach based on machine learning and statistical approximation to foresee bin full events and, thus increase uptime of RVMs. Our approach relies on forecasting the hourly time series of returned beverage containers at a given RVM. We contribute by developing and evaluating an approach for hourly forecasts in a retail setting - this combination of application domain and forecast granularity is novel. A trace-driven simulation confirms that the forecasting-based approach leads to less downtime and costs than naive emptying strategies.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge