Jürgen Schatte

Artificial Intelligence for Sustainability: Facilitating Sustainable Smart Product-Service Systems with Computer Vision

Mar 27, 2023

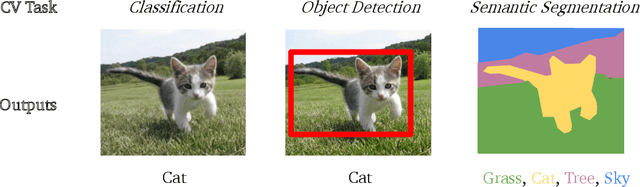

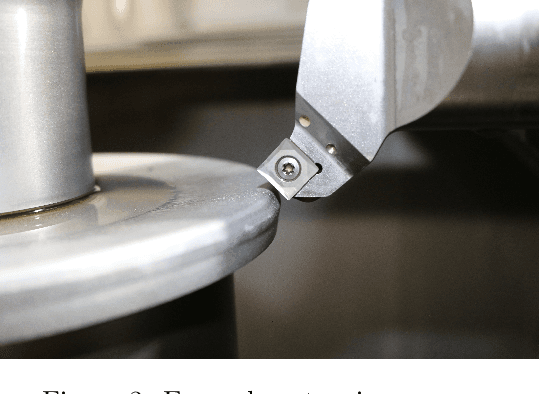

Abstract:The usage and impact of deep learning for cleaner production and sustainability purposes remain little explored. This work shows how deep learning can be harnessed to increase sustainability in production and product usage. Specifically, we utilize deep learning-based computer vision to determine the wear states of products. The resulting insights serve as a basis for novel product-service systems with improved integration and result orientation. Moreover, these insights are expected to facilitate product usage improvements and R&D innovations. We demonstrate our approach on two products: machining tools and rotating X-ray anodes. From a technical standpoint, we show that it is possible to recognize the wear state of these products using deep-learning-based computer vision. In particular, we detect wear through microscopic images of the two products. We utilize a U-Net for semantic segmentation to detect wear based on pixel granularity. The resulting mean dice coefficients of 0.631 and 0.603 demonstrate the feasibility of the proposed approach. Consequently, experts can now make better decisions, for example, to improve the machining process parameters. To assess the impact of the proposed approach on environmental sustainability, we perform life cycle assessments that show gains for both products. The results indicate that the emissions of CO2 equivalents are reduced by 12% for machining tools and by 44% for rotating anodes. This work can serve as a guideline and inspire researchers and practitioners to utilize computer vision in similar scenarios to develop sustainable smart product-service systems and enable cleaner production.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge