Ilya Kovalenko

A Large Language Model-Enabled Control Architecture for Dynamic Resource Capability Exploration in Multi-Agent Manufacturing Systems

May 28, 2025

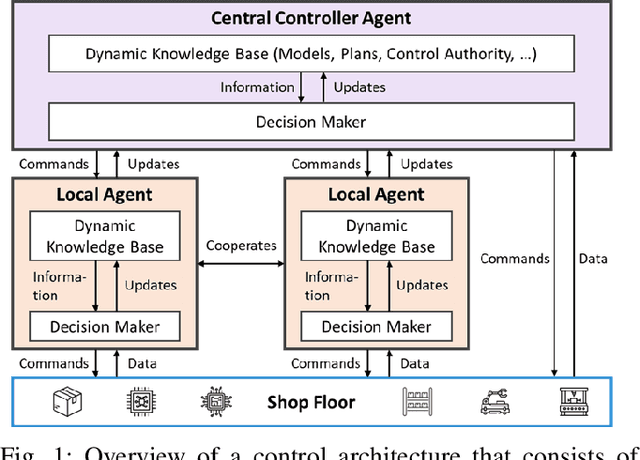

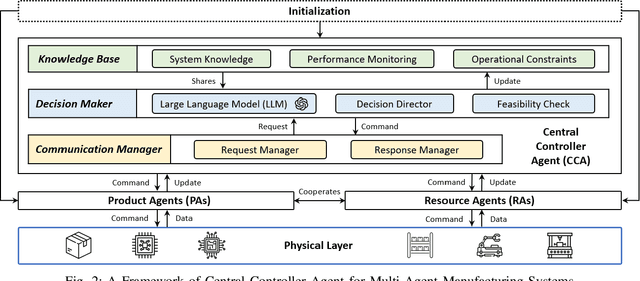

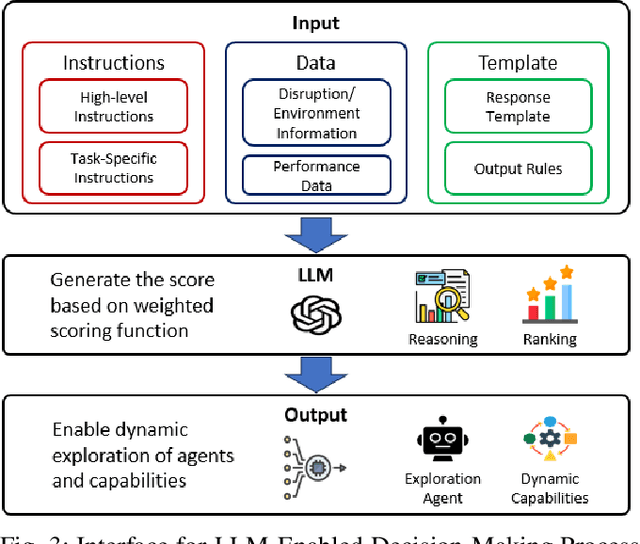

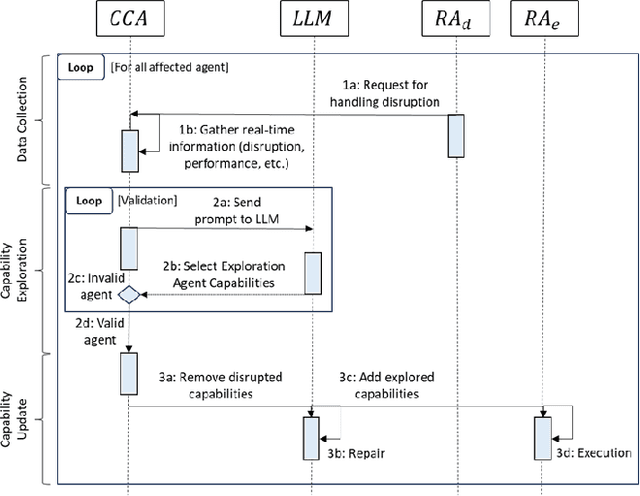

Abstract:Manufacturing environments are becoming more complex and unpredictable due to factors such as demand variations and shorter product lifespans. This complexity requires real-time decision-making and adaptation to disruptions. Traditional control approaches highlight the need for advanced control strategies capable of overcoming unforeseen challenges, as they demonstrate limitations in responsiveness within dynamic industrial settings. Multi-agent systems address these challenges through decentralization of decision-making, enabling systems to respond dynamically to operational changes. However, current multi-agent systems encounter challenges related to real-time adaptation, context-aware decision-making, and the dynamic exploration of resource capabilities. Large language models provide the possibility to overcome these limitations through context-aware decision-making capabilities. This paper introduces a large language model-enabled control architecture for multi-agent manufacturing systems to dynamically explore resource capabilities in response to real-time disruptions. A simulation-based case study demonstrates that the proposed architecture improves system resilience and flexibility. The case study findings show improved throughput and efficient resource utilization compared to existing approaches.

Dynamic Task Adaptation for Multi-Robot Manufacturing Systems with Large Language Models

May 28, 2025Abstract:Recent manufacturing systems are increasingly adopting multi-robot collaboration to handle complex and dynamic environments. While multi-agent architectures support decentralized coordination among robot agents, they often face challenges in enabling real-time adaptability for unexpected disruptions without predefined rules. Recent advances in large language models offer new opportunities for context-aware decision-making to enable adaptive responses to unexpected changes. This paper presents an initial exploratory implementation of a large language model-enabled control framework for dynamic task reassignment in multi-robot manufacturing systems. A central controller agent leverages the large language model's ability to interpret structured robot configuration data and generate valid reassignments in response to robot failures. Experiments in a real-world setup demonstrate high task success rates in recovering from failures, highlighting the potential of this approach to improve adaptability in multi-robot manufacturing systems.

Large Language Model-Enabled Multi-Agent Manufacturing Systems

Jun 04, 2024

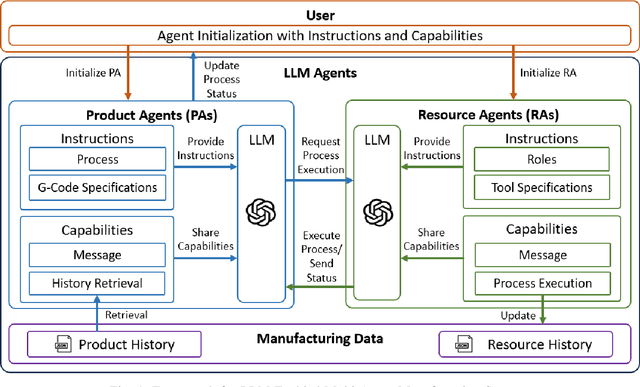

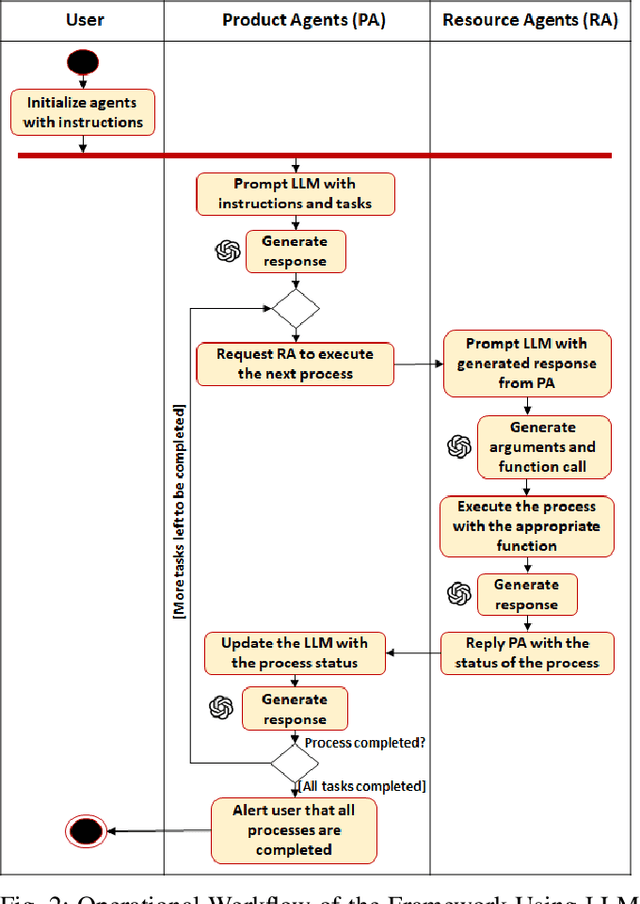

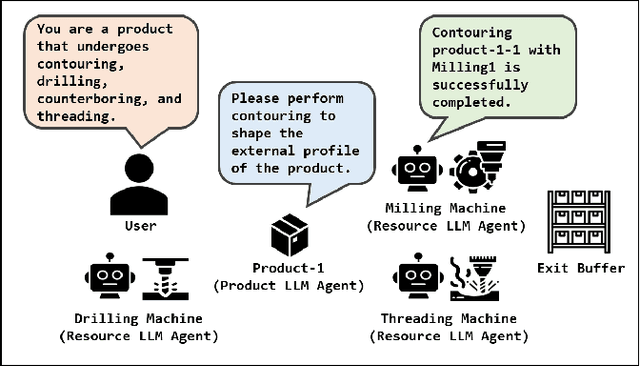

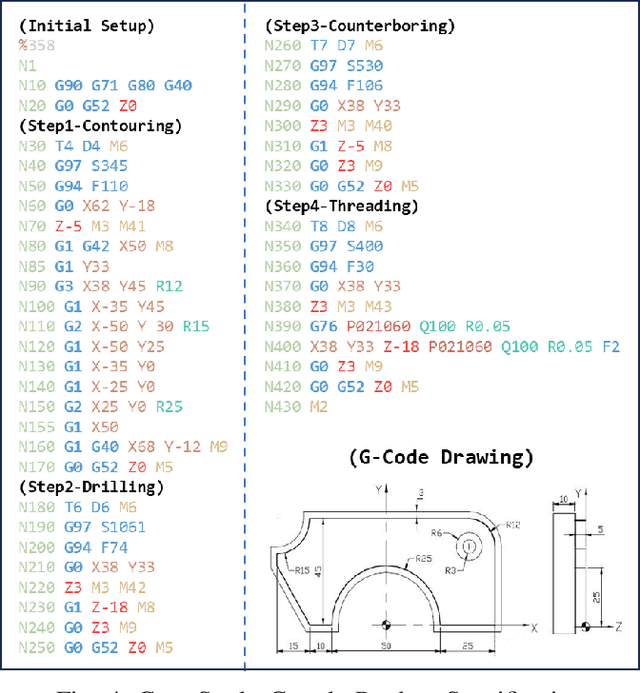

Abstract:Traditional manufacturing faces challenges adapting to dynamic environments and quickly responding to manufacturing changes. The use of multi-agent systems has improved adaptability and coordination but requires further advancements in rapid human instruction comprehension, operational adaptability, and coordination through natural language integration. Large language models like GPT-3.5 and GPT-4 enhance multi-agent manufacturing systems by enabling agents to communicate in natural language and interpret human instructions for decision-making. This research introduces a novel framework where large language models enhance the capabilities of agents in manufacturing, making them more adaptable, and capable of processing context-specific instructions. A case study demonstrates the practical application of this framework, showing how agents can effectively communicate, understand tasks, and execute manufacturing processes, including precise G-code allocation among agents. The findings highlight the importance of continuous large language model integration into multi-agent manufacturing systems and the development of sophisticated agent communication protocols for a more flexible manufacturing system.

Enhancing Human-Robot Collaborative Assembly in Manufacturing Systems Using Large Language Models

Jun 04, 2024Abstract:The development of human-robot collaboration has the ability to improve manufacturing system performance by leveraging the unique strengths of both humans and robots. On the shop floor, human operators contribute with their adaptability and flexibility in dynamic situations, while robots provide precision and the ability to perform repetitive tasks. However, the communication gap between human operators and robots limits the collaboration and coordination of human-robot teams in manufacturing systems. Our research presents a human-robot collaborative assembly framework that utilizes a large language model for enhancing communication in manufacturing environments. The framework facilitates human-robot communication by integrating voice commands through natural language for task management. A case study for an assembly task demonstrates the framework's ability to process natural language inputs and address real-time assembly challenges, emphasizing adaptability to language variation and efficiency in error resolution. The results suggest that large language models have the potential to improve human-robot interaction for collaborative manufacturing assembly applications.

A Mobile Additive Manufacturing Robot Framework for Smart Manufacturing Systems

Apr 19, 2024

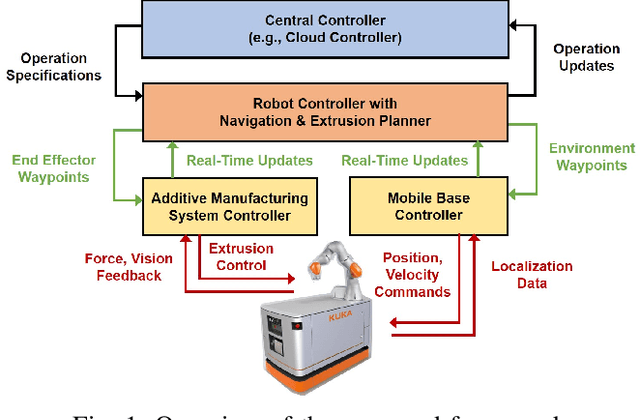

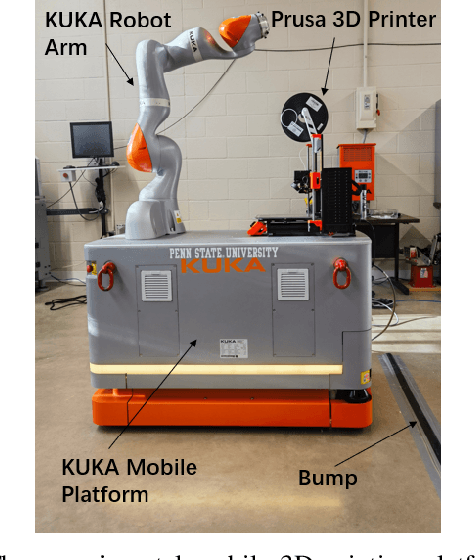

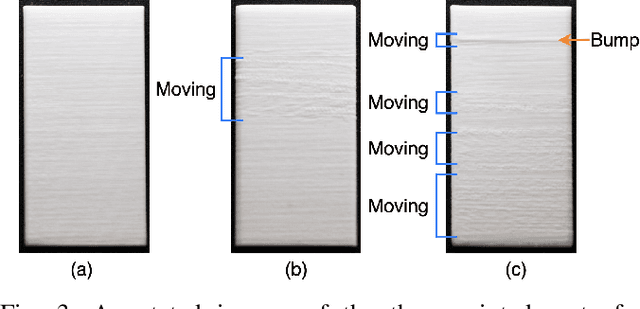

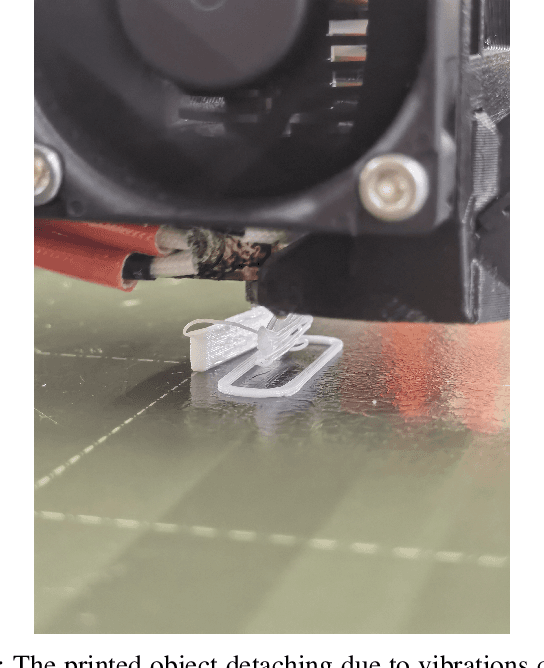

Abstract:Recent technological innovations in the areas of additive manufacturing and collaborative robotics have paved the way toward realizing the concept of on-demand, personalized production on the shop floor. Additive manufacturing process can provide the capability of printing highly customized parts based on various customer requirements. Autonomous, mobile systems provide the flexibility to move custom parts around the shop floor to various manufacturing operations, as needed by product requirements. In this work, we proposed a mobile additive manufacturing robot framework for merging an additive manufacturing process system with an autonomous mobile base. Two case studies showcase the potential benefits of the proposed mobile additive manufacturing framework. The first case study overviews the effect that a mobile system can have on a fused deposition modeling process. The second case study showcases how integrating a mobile additive manufacturing machine can improve the throughput of the manufacturing system. The major findings of this study are that the proposed mobile robotic AM has increased throughput by taking advantage of the travel time between operations/processing sites. It is particularly suited to perform intermittent operations (e.g., preparing feedstock) during the travel time of the robotic AM. One major implication of this study is its application in manufacturing structural components (e.g., concrete construction, and feedstock preparation during reconnaissance missions) in remote or extreme terrains with on-site or on-demand feedstocks.

Opportunities and Challenges to Integrate Artificial Intelligence into Manufacturing Systems: Thoughts from a Panel Discussion

Mar 20, 2023

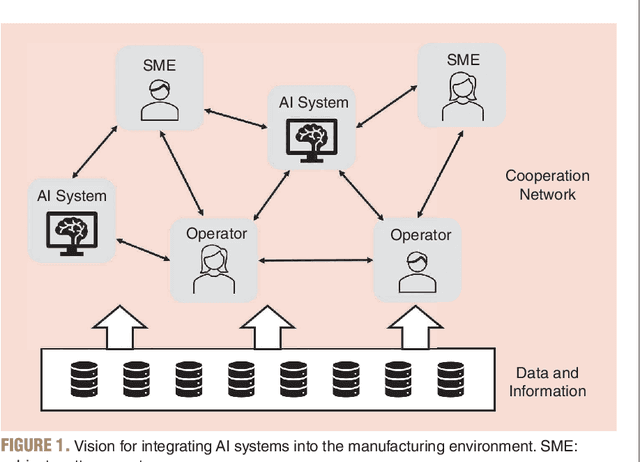

Abstract:Rapid advances in artificial intelligence (AI) have the potential to significantly increase the productivity, quality, and profitability in future manufacturing systems. Traditional mass-production will give way to personalized production, with each item made to order, at the low cost and high-quality consumers have come to expect. Manufacturing systems will have the intelligence to be resilient to multiple disruptions, from small-scale machine breakdowns, to large-scale natural disasters. Products will be made with higher precision and lower variability. While gains have been made towards the development of these factories of the future, many challenges remain to fully realize this vision. To consider the challenges and opportunities associated with this topic, a panel of experts from Industry, Academia, and Government was invited to participate in an active discussion at the 2022 Modeling, Estimation and Control Conference (MECC) held in Jersey City, New Jersey from October 3- 5, 2022. The panel discussion focused on the challenges and opportunities to more fully integrate AI into manufacturing systems. Three overarching themes emerged from the panel discussion. First, to be successful, AI will need to work seamlessly, and in an integrated manner with humans (and vice versa). Second, significant gaps in the infrastructure needed to enable the full potential of AI into the manufacturing ecosystem, including sufficient data availability, storage, and analysis, must be addressed. And finally, improved coordination between universities, industry, and government agencies can facilitate greater opportunities to push the field forward. This article briefly summarizes these three themes, and concludes with a discussion of promising directions.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge