Jonghan Lim

A Large Language Model-Enabled Control Architecture for Dynamic Resource Capability Exploration in Multi-Agent Manufacturing Systems

May 28, 2025

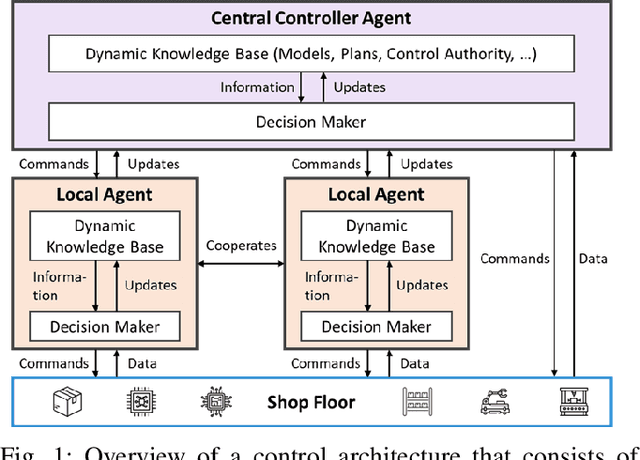

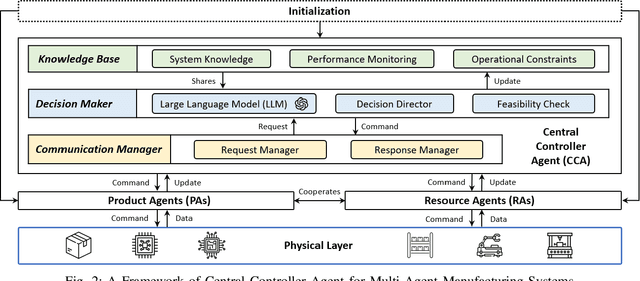

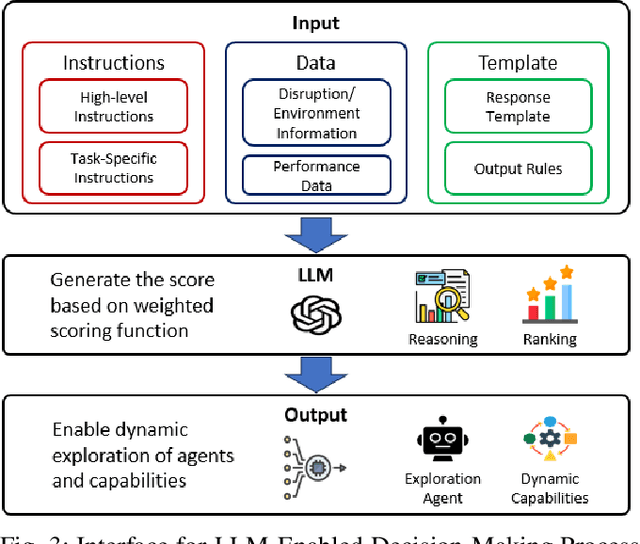

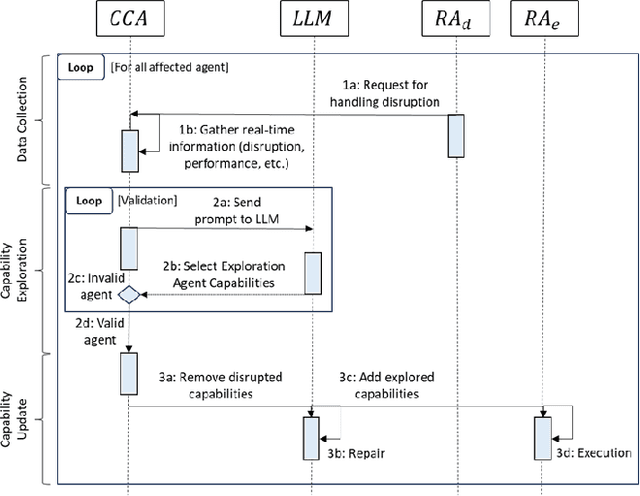

Abstract:Manufacturing environments are becoming more complex and unpredictable due to factors such as demand variations and shorter product lifespans. This complexity requires real-time decision-making and adaptation to disruptions. Traditional control approaches highlight the need for advanced control strategies capable of overcoming unforeseen challenges, as they demonstrate limitations in responsiveness within dynamic industrial settings. Multi-agent systems address these challenges through decentralization of decision-making, enabling systems to respond dynamically to operational changes. However, current multi-agent systems encounter challenges related to real-time adaptation, context-aware decision-making, and the dynamic exploration of resource capabilities. Large language models provide the possibility to overcome these limitations through context-aware decision-making capabilities. This paper introduces a large language model-enabled control architecture for multi-agent manufacturing systems to dynamically explore resource capabilities in response to real-time disruptions. A simulation-based case study demonstrates that the proposed architecture improves system resilience and flexibility. The case study findings show improved throughput and efficient resource utilization compared to existing approaches.

Dynamic Task Adaptation for Multi-Robot Manufacturing Systems with Large Language Models

May 28, 2025Abstract:Recent manufacturing systems are increasingly adopting multi-robot collaboration to handle complex and dynamic environments. While multi-agent architectures support decentralized coordination among robot agents, they often face challenges in enabling real-time adaptability for unexpected disruptions without predefined rules. Recent advances in large language models offer new opportunities for context-aware decision-making to enable adaptive responses to unexpected changes. This paper presents an initial exploratory implementation of a large language model-enabled control framework for dynamic task reassignment in multi-robot manufacturing systems. A central controller agent leverages the large language model's ability to interpret structured robot configuration data and generate valid reassignments in response to robot failures. Experiments in a real-world setup demonstrate high task success rates in recovering from failures, highlighting the potential of this approach to improve adaptability in multi-robot manufacturing systems.

Large Language Model-Enabled Multi-Agent Manufacturing Systems

Jun 04, 2024

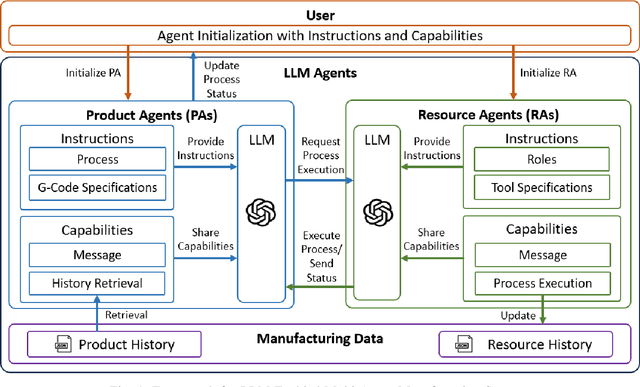

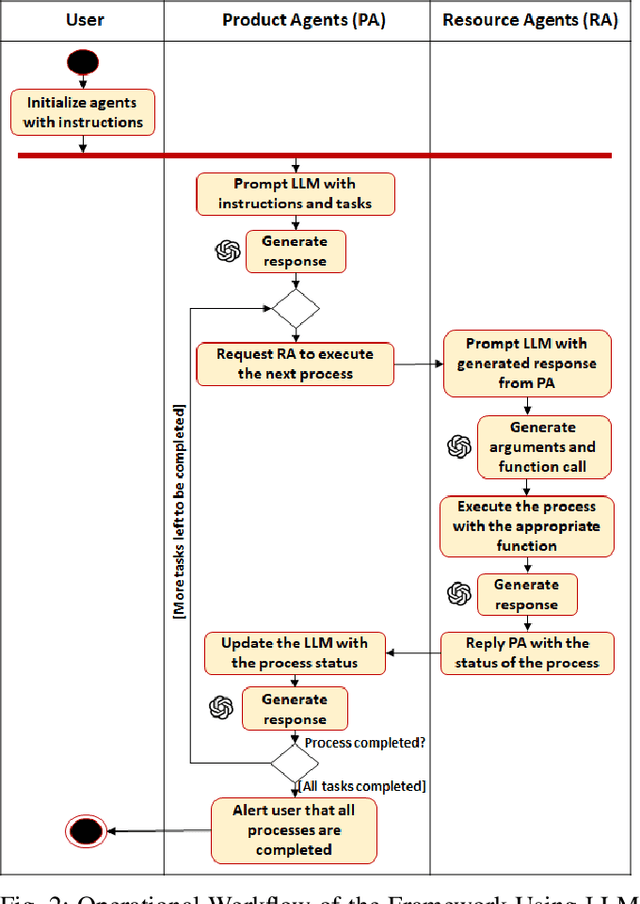

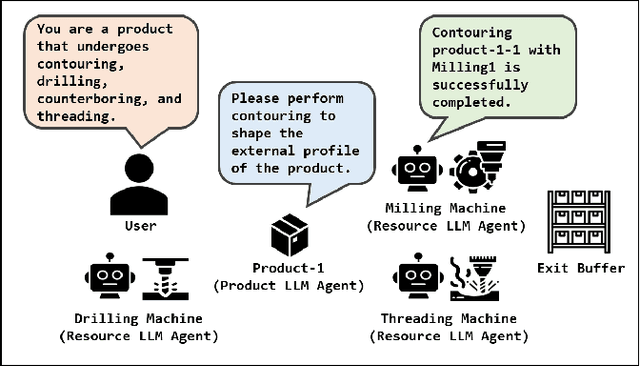

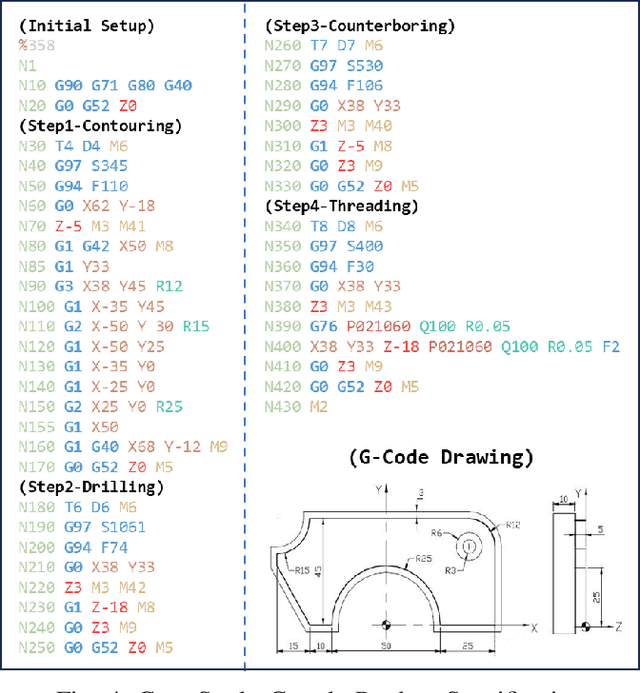

Abstract:Traditional manufacturing faces challenges adapting to dynamic environments and quickly responding to manufacturing changes. The use of multi-agent systems has improved adaptability and coordination but requires further advancements in rapid human instruction comprehension, operational adaptability, and coordination through natural language integration. Large language models like GPT-3.5 and GPT-4 enhance multi-agent manufacturing systems by enabling agents to communicate in natural language and interpret human instructions for decision-making. This research introduces a novel framework where large language models enhance the capabilities of agents in manufacturing, making them more adaptable, and capable of processing context-specific instructions. A case study demonstrates the practical application of this framework, showing how agents can effectively communicate, understand tasks, and execute manufacturing processes, including precise G-code allocation among agents. The findings highlight the importance of continuous large language model integration into multi-agent manufacturing systems and the development of sophisticated agent communication protocols for a more flexible manufacturing system.

Enhancing Human-Robot Collaborative Assembly in Manufacturing Systems Using Large Language Models

Jun 04, 2024Abstract:The development of human-robot collaboration has the ability to improve manufacturing system performance by leveraging the unique strengths of both humans and robots. On the shop floor, human operators contribute with their adaptability and flexibility in dynamic situations, while robots provide precision and the ability to perform repetitive tasks. However, the communication gap between human operators and robots limits the collaboration and coordination of human-robot teams in manufacturing systems. Our research presents a human-robot collaborative assembly framework that utilizes a large language model for enhancing communication in manufacturing environments. The framework facilitates human-robot communication by integrating voice commands through natural language for task management. A case study for an assembly task demonstrates the framework's ability to process natural language inputs and address real-time assembly challenges, emphasizing adaptability to language variation and efficiency in error resolution. The results suggest that large language models have the potential to improve human-robot interaction for collaborative manufacturing assembly applications.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge