Ian Good

Spring-Brake! Handed Shearing Auxetics Improve Efficiency of Hopping and Standing

May 28, 2025Abstract:Energy efficiency is critical to the success of legged robotics. Efficiency is lost through wasted energy during locomotion and standing. Including elastic elements has been shown to reduce movement costs, while including breaks can reduce standing costs. However, adding separate elements for each increases the mass and complexity of a leg, reducing overall system performance. Here we present a novel compliant mechanism using a Handed Shearing Auxetic (HSA) that acts as a spring and break in a monopod hopping robot. The HSA acts as a parallel elastic actuator, reducing electrical power for dynamic hopping and matching the efficiency of state-of-the-art compliant hoppers. The HSA\u2019s auxetic behavior enables dual functionality. During static tasks, it locks under large forces with minimal input power by blocking deformation, creating high friction similar to a capstan mechanism. This allows the leg to support heavy loads without motor torque, addressing thermal inefficiency. The multi-functional design enhances both dynamic and static performance, offering a versatile solution for robotic applications.

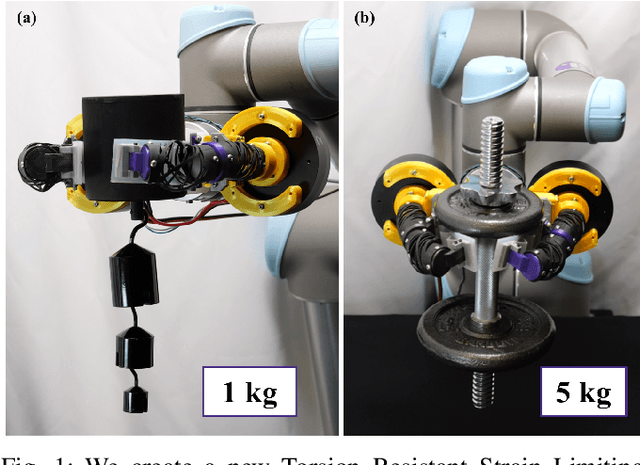

Torsion Resistant Strain Limiting Layers Enable High Grip Strength of Electrically-Driven Handed Shearing Auxetic Grippers

Dec 10, 2024

Abstract:Soft grippers have demonstrated a strong ability to successfully pick and manipulate many objects. A key limitation to their wider adoption is their inability to grasp larger payloads due to objects slipping out of grasps. We have overcome this limitation by introducing a torsionally rigid strain limiting layer (TR-SLL). This reduces out-of-plane bending while maintaining the gripper's softness and in-plane flexibility. We characterize the design space of the strain limiting layer and Handed Shearing Auxetic (HSA) actuators for a soft gripper using simulation and experiment. The inclusion of the TR-SLL with HSAs enables HSA grippers to be made with a single digit. We found that the use of our TR-SLL HSA gripper enabled pinch grasping of payloads over 1 kg. We demonstrate a lifting capacity of 5 kg when loading using the TR-SLL. We also demonstrate a peak pinch grasp force of 5.8 N, and a peak planar caging force of 14.5 N. Finally, we test the TR-SLL gripper on a suite of 43 YCB objects. We show success on 37 objects demonstrating significant capabilities.

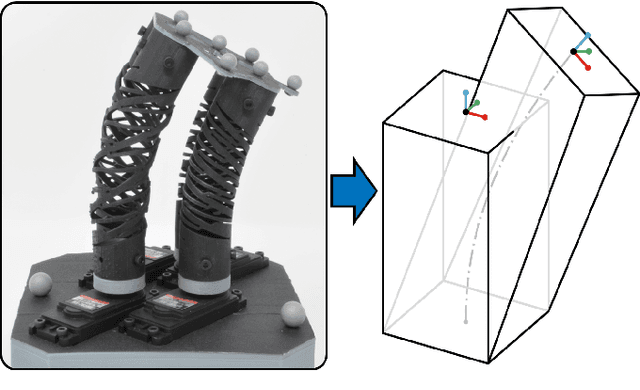

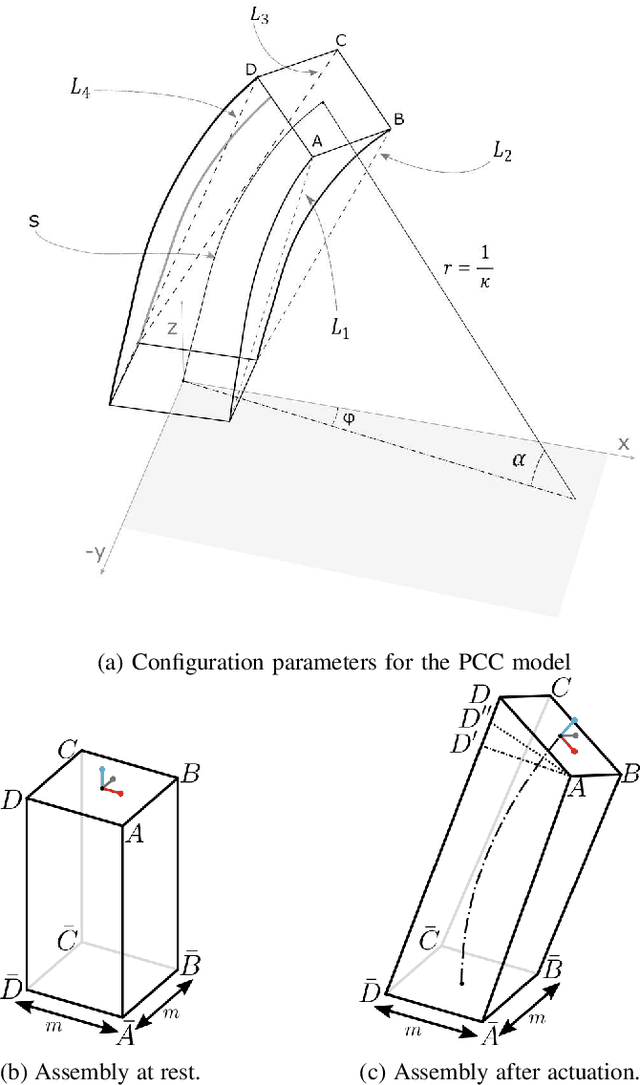

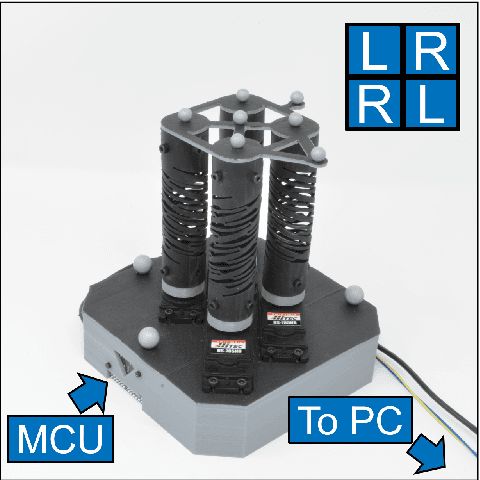

Kinematic Modeling of Handed Shearing Auxetics via Piecewise Constant Curvature

Dec 09, 2021

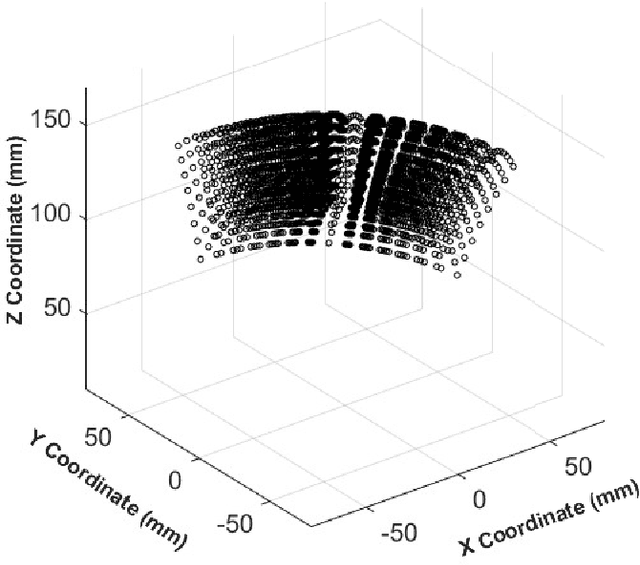

Abstract:Handed Shearing Auxetics (HSA) are a promising technique for making motor-driven, soft, continuum robots. Many potential applications from inspection tasks to solar tracking require accurate kinematic models to predict the position and orientation of these structures. Currently there are no models for HSA based continuum platforms. To address this gap we propose to adapt Piecewise Constant Curvature (PCC) Models using a length change coupling matrix. This models the interaction of HSA structures in a 2x2 array. The coupling matrix maps the change in motor angles to length changes and defines the configuration space in our modified PCC Model. We evaluate our model on a composite movement encompassing bending, extension and compression behavior. Our model achieves a positional accuracy with mean error of 5.5mm or 4.5% body length and standard deviation of 1.72mm. Further, we achieve an angular accuracy with mean error of -2.8$^\circ$ and standard deviation of 1.9$^\circ$.

Expanding the Design Space for Electrically-Driven Soft Robots through Handed Shearing Auxetics

Oct 01, 2021Abstract:Handed Shearing Auxetics (HSA) are a promising structure for making electrically driven robots with distributed compliance that convert a motors rotation and torque into extension and force. We overcame past limitations on the range of actuation, blocked force, and stiffness by focusing on two key design parameters: the point of an HSA's auxetic trajectory that is energetically preferred, and the number of cells along the HSAs length. Modeling the HSA as a programmable spring, we characterize the effect of both on blocked force, minimum energy length, spring constant, angle range and holding torque. We also examined the effect viscoelasticity has on actuation forces over time. By varying the auxetic trajectory point, we were able to make actuators that can push, pull, or do both. We expanded the range of forces possible from 5N to 150N, and the range of stiffness from 2 N/mm to 89 N/mm. For a fixed point on the auxetic trajectory, we found decreasing length can improve force output, at the expense of needing higher torques, and having a shorter throw. We also found that the viscoelastic effects can limit the amount of force a 3D printed HSA can apply over time.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge