Jeffrey Ian Lipton

Robots That Generate Planarity Through Geometry

Feb 06, 2026Abstract:Constraining motion to a flat surface is a fundamental requirement for equipment across science and engineering. Modern precision robotic motion systems, such as gantries, rely on the flatness of components, including guide rails and granite surface plates. However, translating this static flatness into motion requires precise internal alignment and tight-tolerance components that create long, error-sensitive reference chains. Here, we show that by using the geometric inversion of a sphere into a plane, we can produce robotic motion systems that derive planarity entirely from link lengths and connectivity. This allows planar motion to emerge from self-referencing geometric constraints, and without external metrology. We demonstrate these Flat-Plane Mechanisms (FPMs) from micron to meter scales and show that fabrication errors can be attenuated by an order of magnitude in the resulting flatness. Finally, we present a robotic FPM-based 3-axis positioning system that can be used for metrology surface scans ($\pm 12$-mm) and 3D printing inside narrow containers. This work establishes an alternative geometric foundation for planar motion that can be realized across size scales and opens new possibilities in metrology, fabrication, and micro-positioning.

SCCRUB: Surface Cleaning Compliant Robot Utilizing Bristles

Jul 08, 2025Abstract:Scrubbing surfaces is a physically demanding and time-intensive task. Removing adhered contamination requires substantial friction generated through pressure and torque or high lateral forces. Rigid robotic manipulators, while capable of exerting these forces, are usually confined to structured environments isolated from humans due to safety risks. In contrast, soft robot arms can safely work around humans and adapt to environmental uncertainty, but typically struggle to transmit the continuous torques or lateral forces necessary for scrubbing. Here, we demonstrate a soft robotic arm scrubbing adhered residues using torque and pressure, a task traditionally challenging for soft robots. We train a neural network to learn the arm's inverse kinematics and elasticity, which enables open-loop force and position control. Using this learned model, the robot successfully scrubbed burnt food residue from a plate and sticky fruit preserve from a toilet seat, removing an average of 99.7% of contamination. This work demonstrates how soft robots, capable of exerting continuous torque, can effectively and safely scrub challenging contamination from surfaces.

Spring-Brake! Handed Shearing Auxetics Improve Efficiency of Hopping and Standing

May 28, 2025Abstract:Energy efficiency is critical to the success of legged robotics. Efficiency is lost through wasted energy during locomotion and standing. Including elastic elements has been shown to reduce movement costs, while including breaks can reduce standing costs. However, adding separate elements for each increases the mass and complexity of a leg, reducing overall system performance. Here we present a novel compliant mechanism using a Handed Shearing Auxetic (HSA) that acts as a spring and break in a monopod hopping robot. The HSA acts as a parallel elastic actuator, reducing electrical power for dynamic hopping and matching the efficiency of state-of-the-art compliant hoppers. The HSA\u2019s auxetic behavior enables dual functionality. During static tasks, it locks under large forces with minimal input power by blocking deformation, creating high friction similar to a capstan mechanism. This allows the leg to support heavy loads without motor torque, addressing thermal inefficiency. The multi-functional design enhances both dynamic and static performance, offering a versatile solution for robotic applications.

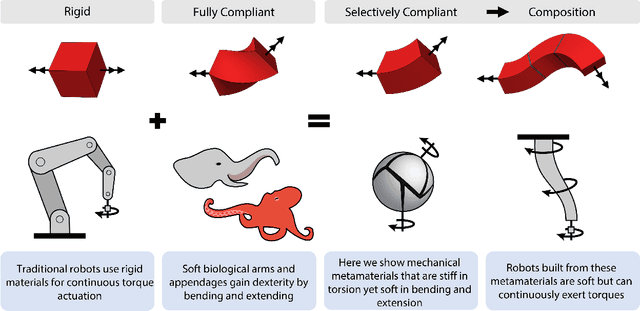

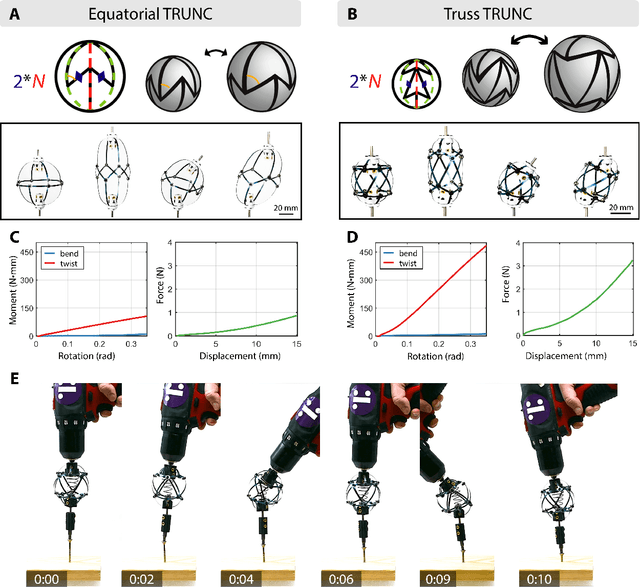

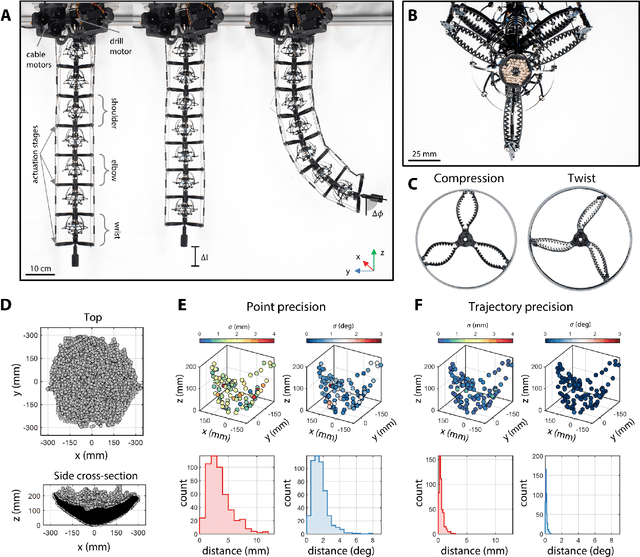

Bridging Hard and Soft: Mechanical Metamaterials Enable Rigid Torque Transmission in Soft Robots

Dec 03, 2024

Abstract:Torque and continuous rotation are fundamental methods of actuation and manipulation in rigid robots. Soft robot arms use soft materials and structures to mimic the passive compliance of biological arms that bend and extend. This use of compliance prevents soft arms from continuously transmitting and exerting torques to interact with their environment. Here, we show how relying on patterning structures instead of inherent material properties allows soft robotic arms to remain compliant while continuously transmitting torque to their environment. We demonstrate a soft robotic arm made from a pair of mechanical metamaterials that act as compliant constant-velocity joints. The joints are up to 52 times stiffer in torsion than bending and can bend up to 45{\deg}. This robot arm can continuously transmit torque while deforming in all other directions. The arm's mechanical design achieves high motion repeatability (0.4 mm and 0.1{\deg}) when tracking trajectories. We then trained a neural network to learn the inverse kinematics, enabling us to program the arm to complete tasks that are challenging for existing soft robots such as installing light bulbs, fastening bolts, and turning valves. The arm's passive compliance makes it safe around humans and provides a source of mechanical intelligence, enabling it to adapt to misalignment when manipulating objects. This work will bridge the gap between hard and soft robotics with applications in human assistance, warehouse automation, and extreme environments.

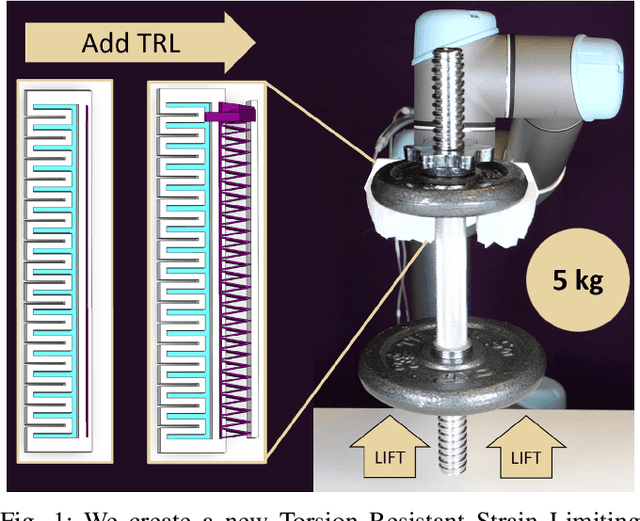

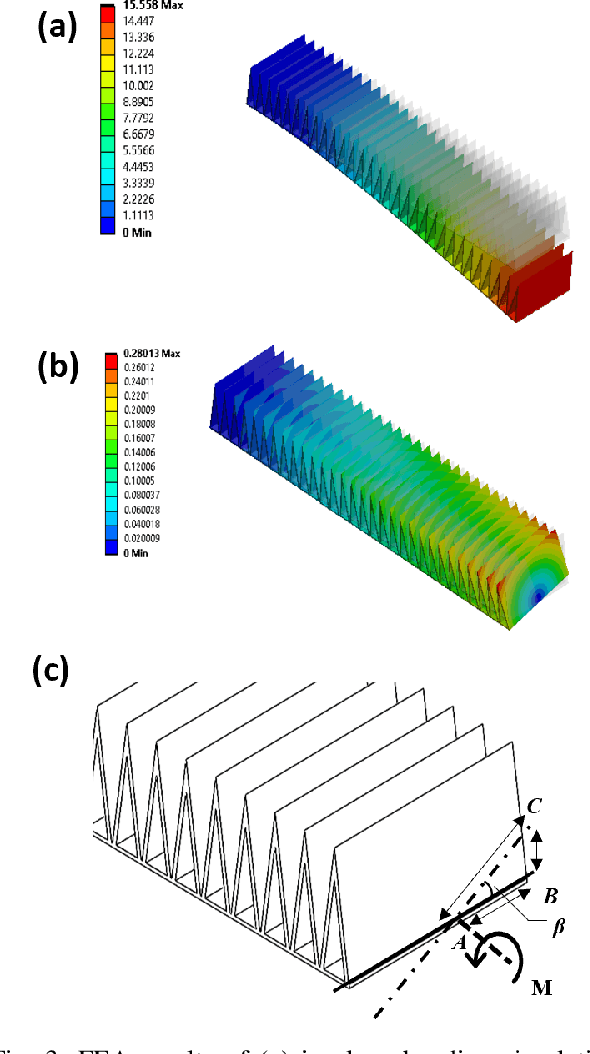

Enhancing the Performance of Pneu-net Actuators Using a Torsion Resistant Strain Limiting Layer

Nov 04, 2023

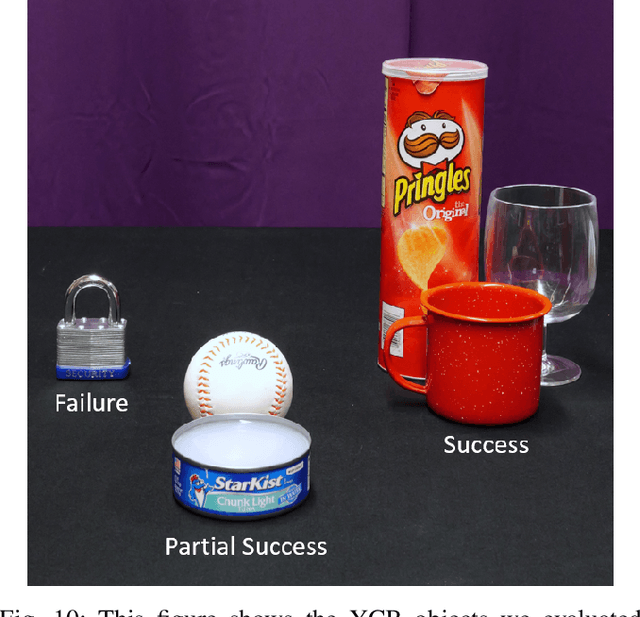

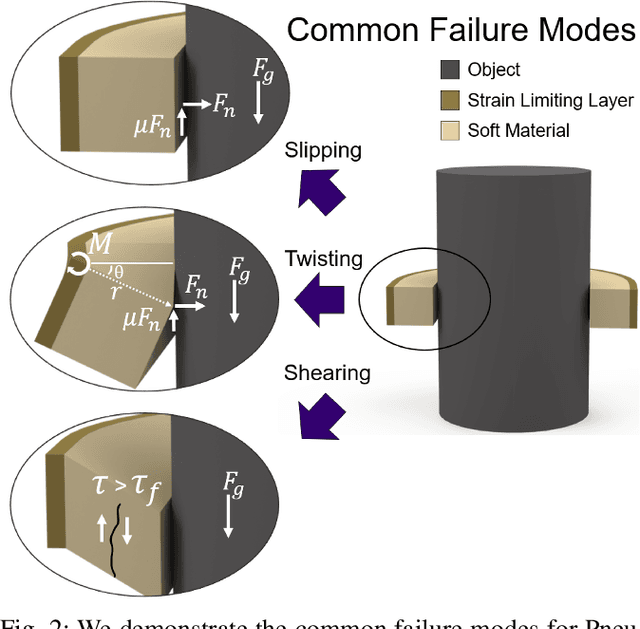

Abstract:Pneunets are the primary form of soft robotic grippers. A key limitation to their wider adoption is their inability to grasp larger payloads due to objects slipping out of grasps. We have overcome this limitation by introducing a torsionally rigid strain limiting layer (TRL). This reduces out-of-plane bending while maintaining the gripper's softness and in-plane flexibility. We characterize the design space of the strain limiting layer for a Pneu-net gripper using simulation and experiment and map bending angle and relative grip strength. We found that the use of our TRL reduced out-of-plane bending by up to 97.7% in testing compared to a benchmark Pneu-net gripper from the Soft Robotics Toolkit. We demonstrate a lifting capacity of 5kg when loading using the TRL. We also see a relative improvement in peak grip force of 3N and stiffness of 1200N/m compared to 1N and 150N/m for a Pneu-net gripper without our TRL at equal pressures. Finally, we test the TRL gripper on a suite of six YCB objects above the demonstrated capability of a traditional Pneu-net gripper. We show success on all but one demonstrating significant increased capabilities.

Expanding the Design Space for Electrically-Driven Soft Robots through Handed Shearing Auxetics

Oct 01, 2021Abstract:Handed Shearing Auxetics (HSA) are a promising structure for making electrically driven robots with distributed compliance that convert a motors rotation and torque into extension and force. We overcame past limitations on the range of actuation, blocked force, and stiffness by focusing on two key design parameters: the point of an HSA's auxetic trajectory that is energetically preferred, and the number of cells along the HSAs length. Modeling the HSA as a programmable spring, we characterize the effect of both on blocked force, minimum energy length, spring constant, angle range and holding torque. We also examined the effect viscoelasticity has on actuation forces over time. By varying the auxetic trajectory point, we were able to make actuators that can push, pull, or do both. We expanded the range of forces possible from 5N to 150N, and the range of stiffness from 2 N/mm to 89 N/mm. For a fixed point on the auxetic trajectory, we found decreasing length can improve force output, at the expense of needing higher torques, and having a shorter throw. We also found that the viscoelastic effects can limit the amount of force a 3D printed HSA can apply over time.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge