Erva Ulu

PATO: Producibility-Aware Topology Optimization using Deep Learning for Metal Additive Manufacturing

Dec 08, 2021

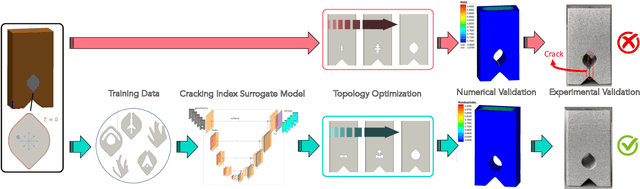

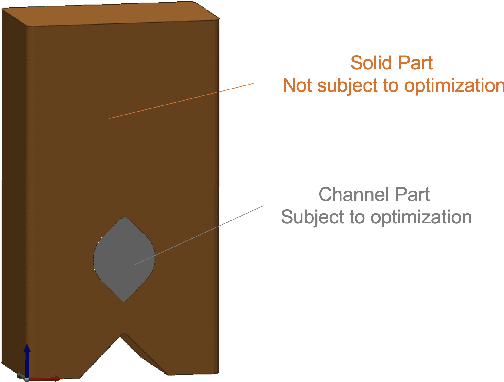

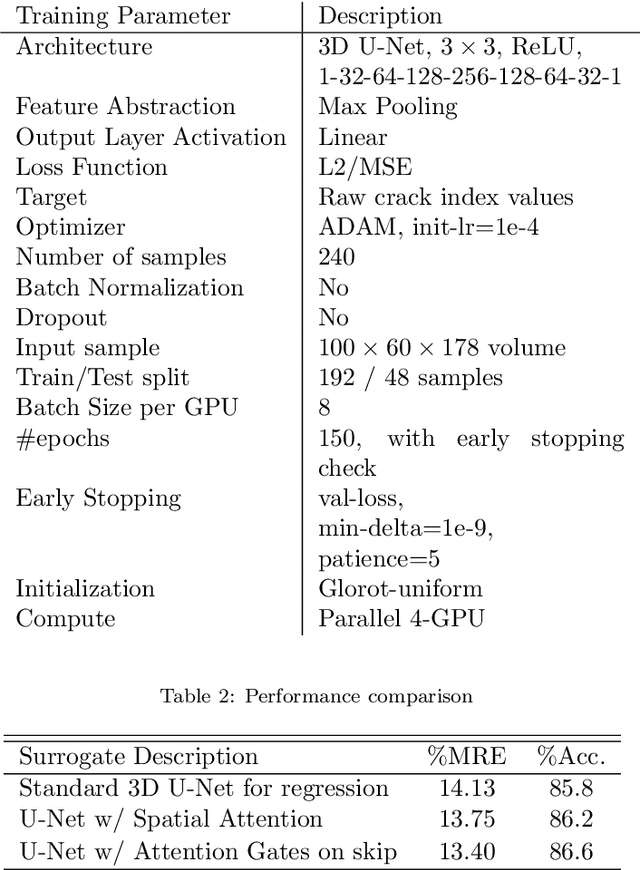

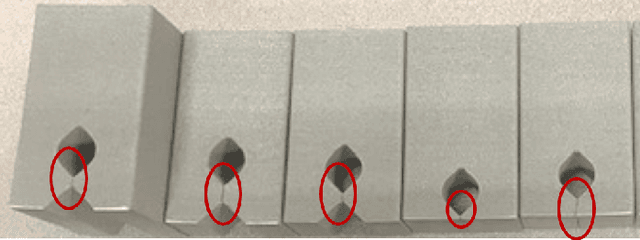

Abstract:In this paper, we propose PATO-a producibility-aware topology optimization (TO) framework to help efficiently explore the design space of components fabricated using metal additive manufacturing (AM), while ensuring manufacturability with respect to cracking. Specifically, parts fabricated through Laser Powder Bed Fusion are prone to defects such as warpage or cracking due to high residual stress values generated from the steep thermal gradients produced during the build process. Maturing the design for such parts and planning their fabrication can span months to years, often involving multiple handoffs between design and manufacturing engineers. PATO is based on the a priori discovery of crack-free designs, so that the optimized part can be built defect-free at the outset. To ensure that the design is crack free during optimization, producibility is explicitly encoded within the standard formulation of TO, using a crack index. Multiple crack indices are explored and using experimental validation, maximum shear strain index (MSSI) is shown to be an accurate crack index. Simulating the build process is a coupled, multi-physics computation and incorporating it in the TO loop can be computationally prohibitive. We leverage the current advances in deep convolutional neural networks and present a high-fidelity surrogate model based on an Attention-based U-Net architecture to predict the MSSI values as a spatially varying field over the part's domain. Further, we employ automatic differentiation to directly compute the gradient of maximum MSSI with respect to the input design variables and augment it with the performance-based sensitivity field to optimize the design while considering the trade-off between weight, manufacturability, and functionality. We demonstrate the effectiveness of the proposed method through benchmark studies in 3D as well as experimental validation.

Structural Design Using Laplacian Shells

Jun 25, 2019

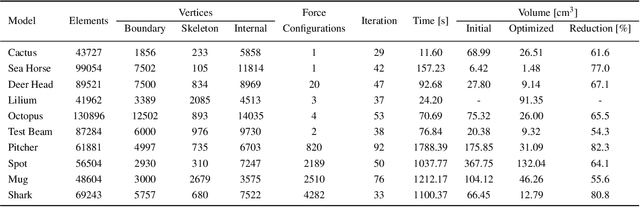

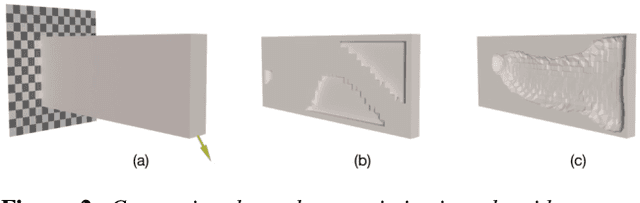

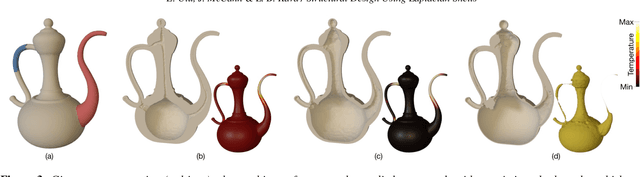

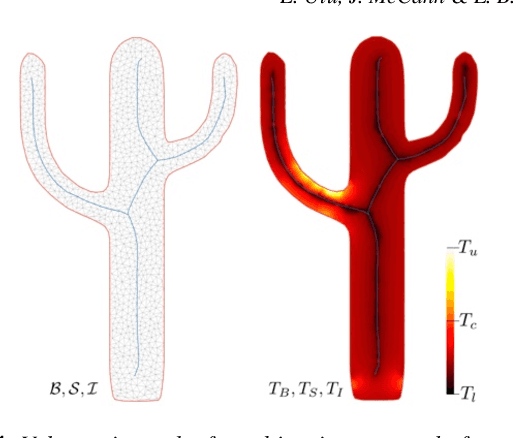

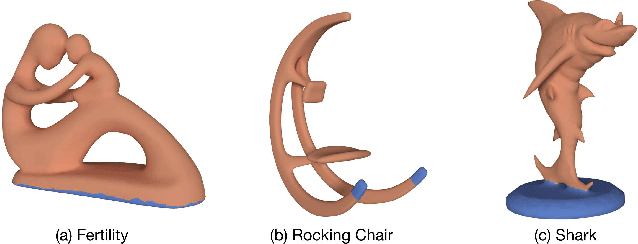

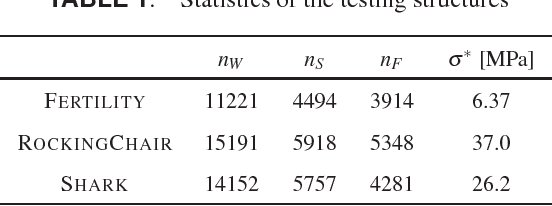

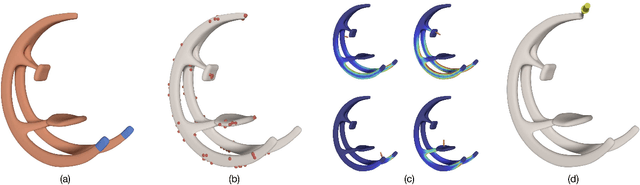

Abstract:We introduce a method to design lightweight shell objects that are structurally robust under the external forces they may experience during use. Given an input 3D model and a general description of the external forces, our algorithm generates a structurally-sound minimum weight shell object. Our approach works by altering the local shell thickness repeatedly based on the stresses that develop inside the object. A key issue in shell design is that large thickness values might result in self-intersections on the inner boundary creating a significant computational challenge during optimization. To address this, we propose a shape parametrization based on the solution to the Laplace's equation that guarantees smooth and intersection-free shell boundaries. Combined with our gradient-free optimization algorithm, our method provides a practical solution to the structural design of hollow objects with a single inner cavity. We demonstrate our method on a variety of problems with arbitrary 3D models under complex force configurations and validate its performance with physical experiments.

Enhancing the Structural Performance of Additively Manufactured Objects

Nov 01, 2018

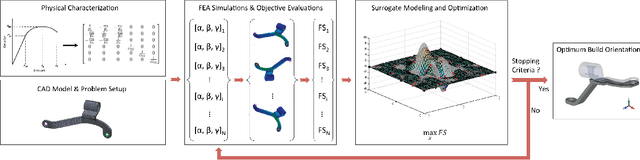

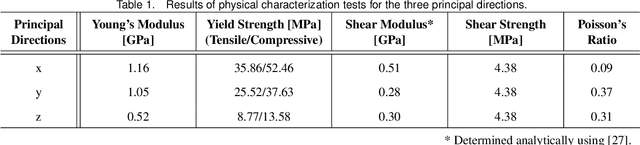

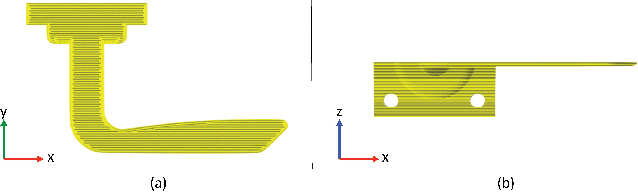

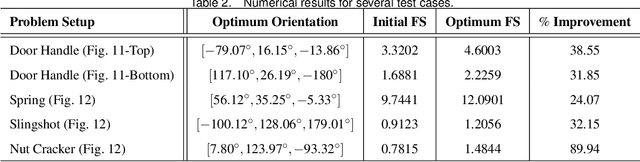

Abstract:The ability to accurately quantify the performance an additively manufactured (AM) product is important for a widespread industry adoption of AM as the design is required to: (1) satisfy geometrical constraints, (2) satisfy structural constraints dictated by its intended function, and (3) be cost effective compared to traditional manufacturing methods. Optimization techniques offer design aids in creating cost-effective structures that meet the prescribed structural objectives. The fundamental problem in existing approaches lies in the difficulty to quantify the structural performance as each unique design leads to a new set of analyses to determine the structural robustness and such analyses can be very costly due to the complexity of in-use forces experienced by the structure. This work develops computationally tractable methods tailored to maximize the structural performance of AM products. A geometry preserving build orientation optimization method as well as data-driven shape optimization approaches to structural design are presented. Proposed methods greatly enhance the value of AM technology by taking advantage of the design space enabled by it for a broad class of problems involving complex in-use loads.

Efficient Load Sampling for Worst-Case Structural Analysis Under Force Location Uncertainty

Oct 25, 2018

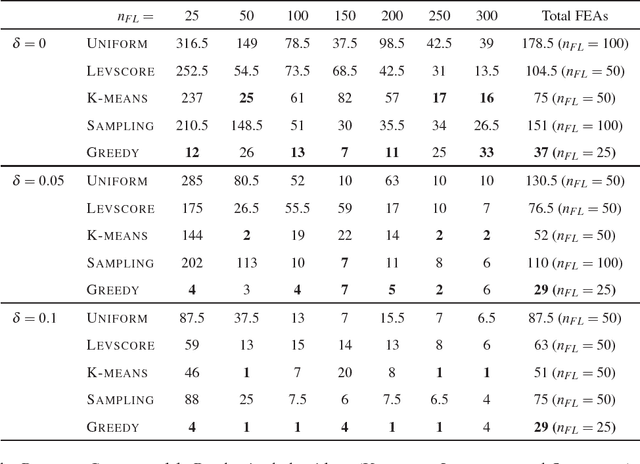

Abstract:An important task in structural design is to quantify the structural performance of an object under the external forces it may experience during its use. The problem proves to be computationally very challenging as the external forces' contact locations and magnitudes may exhibit significant variations. We present an efficient analysis approach to determine the most critical force contact location in such problems with force location uncertainty. Given an input 3D model and regions on its boundary where arbitrary normal forces may make contact, our algorithm predicts the worst-case force configuration responsible for creating the highest stress within the object. Our approach uses a computationally tractable experimental design method to select number of sample force locations based on geometry only, without inspecting the stress response that requires computationally expensive finite-element analysis. Then, we construct a simple regression model on these samples and corresponding maximum stresses. Combined with a simple ranking based post-processing step, our method provides a practical solution to worst-case structural analysis problem. The results indicate that our approach achieves significant improvements over the existing work and brute force approaches. We demonstrate that further speed- up can be obtained when small amount of an error tolerance in maximum stress is allowed.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge