Amir M. Mirzendehdel

Co-design Optimization of Moving Parts for Compliance and Collision Avoidance

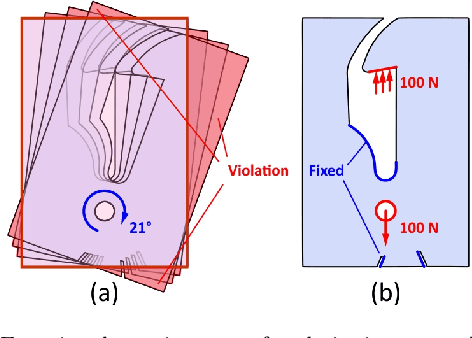

Mar 31, 2025Abstract:Design requirements for moving parts in mechanical assemblies are typically specified in terms of interactions with other parts. Some are purely kinematic (e.g., pairwise collision avoidance) while others depend on physics and material properties (e.g., deformation under loads). Kinematic design methods and physics-based shape/topology optimization (SO/TO) deal separately with these requirements. They rarely talk to each other as the former uses set algebra and group theory while the latter requires discretizing and solving differential equations. Hence, optimizing a moving part based on physics typically relies on either neglecting or pruning kinematic constraints in advance, e.g., by restricting the design domain to a collision-free space using an unsweep operation. In this paper, we show that TO can be used to co-design two or more parts in relative motion to simultaneously satisfy physics-based criteria and collision avoidance. We restrict our attention to maximizing linear-elastic stiffness while penalizing collision measures aggregated in time. We couple the TO loops for two parts in relative motion so that the evolution of each part's shape is accounted for when penalizing collision for the other part. The collision measures are computed by a correlation functional that can be discretized by left- and right-multiplying the shape design variables by a pre-computed matrix that depends solely on the motion. This decoupling is key to making the computations scalable for TO iterations. We demonstrate the effectiveness of the approach with 2D and 3D examples.

PATO: Producibility-Aware Topology Optimization using Deep Learning for Metal Additive Manufacturing

Dec 08, 2021

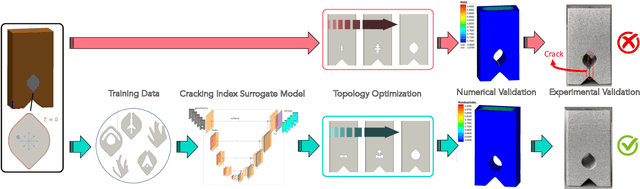

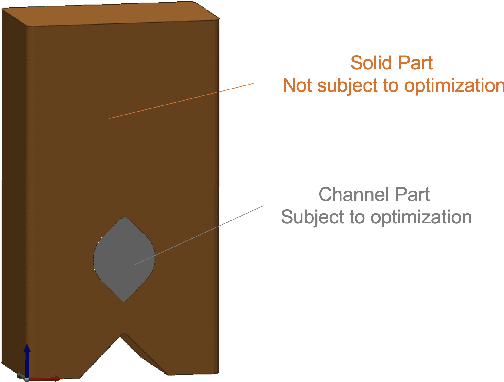

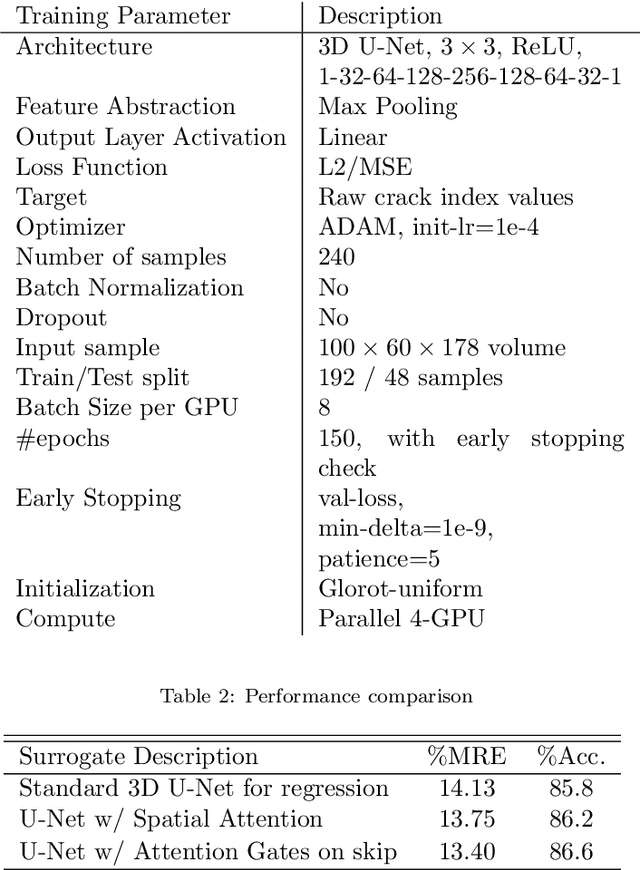

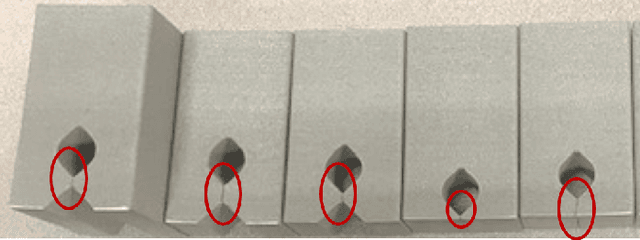

Abstract:In this paper, we propose PATO-a producibility-aware topology optimization (TO) framework to help efficiently explore the design space of components fabricated using metal additive manufacturing (AM), while ensuring manufacturability with respect to cracking. Specifically, parts fabricated through Laser Powder Bed Fusion are prone to defects such as warpage or cracking due to high residual stress values generated from the steep thermal gradients produced during the build process. Maturing the design for such parts and planning their fabrication can span months to years, often involving multiple handoffs between design and manufacturing engineers. PATO is based on the a priori discovery of crack-free designs, so that the optimized part can be built defect-free at the outset. To ensure that the design is crack free during optimization, producibility is explicitly encoded within the standard formulation of TO, using a crack index. Multiple crack indices are explored and using experimental validation, maximum shear strain index (MSSI) is shown to be an accurate crack index. Simulating the build process is a coupled, multi-physics computation and incorporating it in the TO loop can be computationally prohibitive. We leverage the current advances in deep convolutional neural networks and present a high-fidelity surrogate model based on an Attention-based U-Net architecture to predict the MSSI values as a spatially varying field over the part's domain. Further, we employ automatic differentiation to directly compute the gradient of maximum MSSI with respect to the input design variables and augment it with the performance-based sensitivity field to optimize the design while considering the trade-off between weight, manufacturability, and functionality. We demonstrate the effectiveness of the proposed method through benchmark studies in 3D as well as experimental validation.

Exploring Feasible Design Spaces for Heterogeneous Constraints

Jul 10, 2019

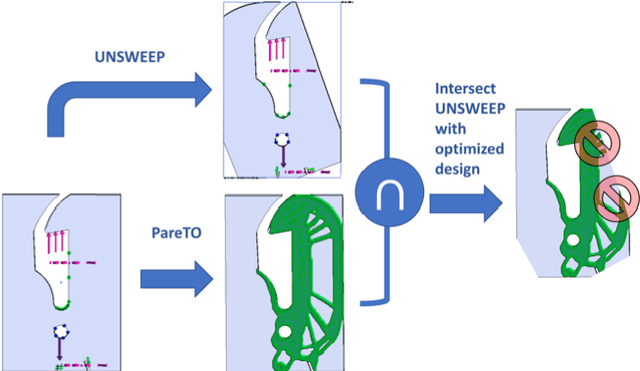

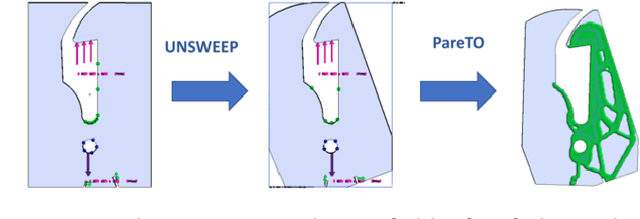

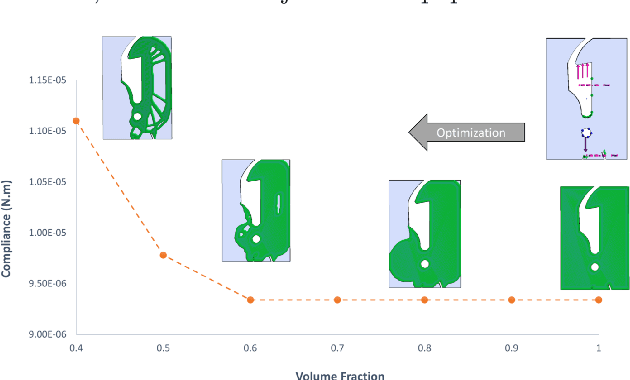

Abstract:We demonstrate an approach of exploring design spaces to simultaneously satisfy kinematics- and physics-based requirements. We present a classification of constraints and solvers to enable postponing optimization as far down the design workflow as possible. The solvers are organized into two broad classes of design space 'pruning' and 'exploration' by considering the types of constraints they can satisfy. We show that pointwise constraints define feasible design subspaces that can be represented and computed as first-class entities by their maximal feasible elements. The design space is pruned upfront by intersecting maximal elements, without premature optimization. To solve for other constraints, we apply topology optimization (TO), starting from the pruned feasible space. The optimization is steered by a topological sensitivity field (TSF) that measures the global changes in violation of constraints with respect to local topological punctures. The TSF for global objective functions is augmented with TSF for global constraints, and penalized/filtered to incorporate local constraints, including set constraints converted to differentiable (in)equality constraints. We demonstrate application of the proposed workflow to nontrivial examples in design and manufacturing. Among other examples, we show how to explore pruned design spaces via TO to simultaneously satisfy physics-based constraints (e.g., minimize compliance and mass) as well as kinematics-based constraints (e.g., maximize accessibility for machining).

* Special Issue on Generative Design

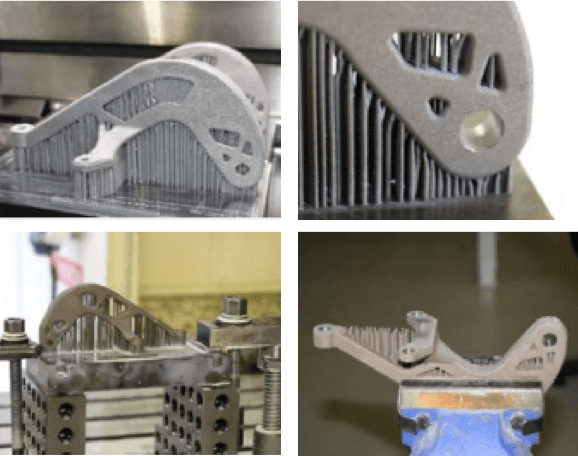

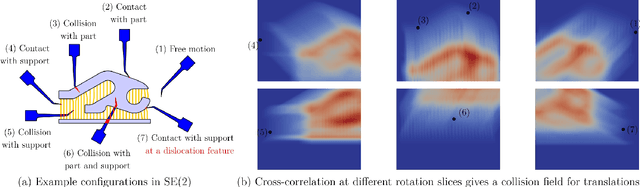

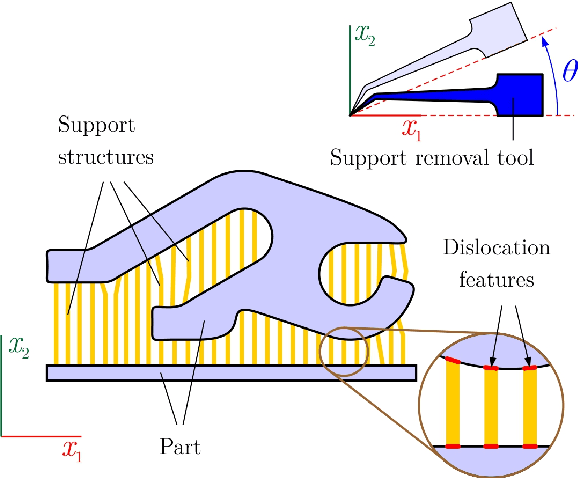

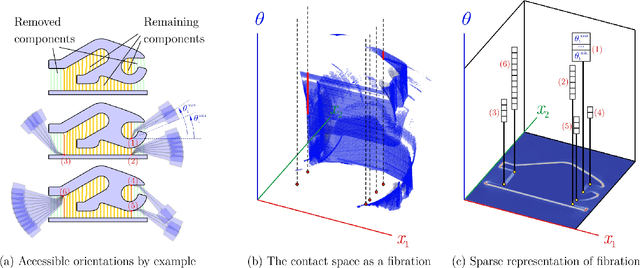

Automatic Support Removal for Additive Manufacturing Post Processing

May 28, 2019

Abstract:An additive manufacturing (AM) process often produces a {\it near-net} shape that closely conforms to the intended design to be manufactured. It sometimes contains additional support structure (also called scaffolding), which has to be removed in post-processing. We describe an approach to automatically generate process plans for support removal using a multi-axis machining instrument. The goal is to fracture the contact regions between each support component and the part, and to do it in the most cost-effective order while avoiding collisions with evolving near-net shape, including the remaining support components. A recursive algorithm identifies a maximal collection of support components whose connection regions to the part are accessible as well as the orientations at which they can be removed at a given round. For every such region, the accessible orientations appear as a 'fiber' in the collision-free space of the evolving near-net shape and the tool assembly. To order the removal of accessible supports, the algorithm constructs a search graph whose edges are weighted by the Riemannian distance between the fibers. The least expensive process plan is obtained by solving a traveling salesman problem (TSP) over the search graph. The sequence of configurations obtained by solving TSP is used as the input to a motion planner that finds collision free paths to visit all accessible features. The resulting part without the support structure can then be finished using traditional machining to produce the intended design. The effectiveness of the method is demonstrated through benchmark examples in 3D.

* Special Issue on symposium on Solid and Physical Modeling (SPM'2019)

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge