Enrico Villagrossi

Hiding task-oriented programming complexity: an industrial case study

Mar 04, 2023Abstract:The ease of use of robot programming interfaces represents a barrier to robot adoption in several manufacturing sectors because of the need for more expertise from the end-users. Current robot programming methods are mostly the past heritage, with robot programmers reluctant to adopt new programming paradigms. This work aims to evaluate the impact on non-expert users of introducing a new task-oriented programming interface that hides the complexity of a programming framework based on ROS. The paper compares the programming performance of such an interface with a classic robot-oriented programming method based on a state-of-the-art robot teach pendant. An experimental campaign involved 22 non-expert users working on the programming of two industrial tasks. Task-oriented and robot-oriented programming showed comparable learning time, programming time and the number of questions raised during the programming phases, highlighting the possibility of a smooth introduction to task-oriented programming even to non-expert users.

Co-manipulation of soft-materials estimating deformation from depth images

Jan 13, 2023Abstract:Human-robot co-manipulation of soft materials, such as fabrics, composites, and sheets of paper/cardboard, is a challenging operation that presents several relevant industrial applications. Estimating the deformation state of the co-manipulated material is one of the main challenges. Viable methods provide the indirect measure by calculating the human-robot relative distance. In this paper, we develop a data-driven model to estimate the deformation state of the material from a depth image through a Convolutional Neural Network (CNN). First, we define the deformation state of the material as the relative roto-translation from the current robot pose and a human grasping position. The model estimates the current deformation state through a Convolutional Neural Network, specifically a DenseNet-121 pretrained on ImageNet.The delta between the current and the desired deformation state is fed to the robot controller that outputs twist commands. The paper describes the developed approach to acquire, preprocess the dataset and train the model. The model is compared with the current state-of-the-art method based on a skeletal tracker from cameras. Results show that our approach achieves better performances and avoids the various drawbacks caused by using a skeletal tracker.Finally, we also studied the model performance according to different architectures and dataset dimensions to minimize the time required for dataset acquisition

In Situ Translational Hand-Eye Calibration of Laser Profile Sensors using Arbitrary Objects

Mar 22, 2021

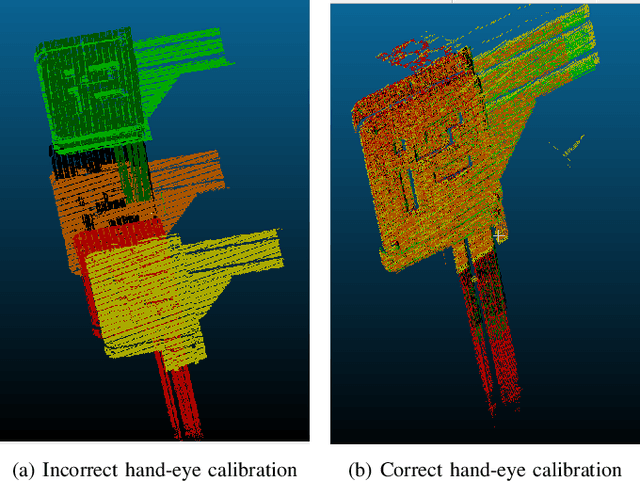

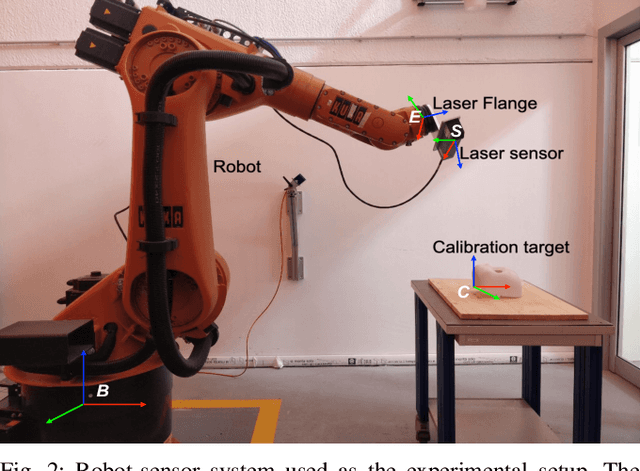

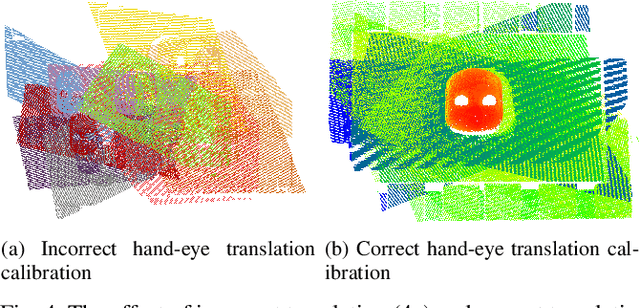

Abstract:Hand-eye calibration of laser profile sensors is the process of extracting the homogeneous transformation between the laser profile sensor frame and the end-effector frame of a robot in order to express the data extracted by the sensor in the robot's global coordinate system. For laser profile scanners this is a challenging procedure, as they provide data only in two dimensions and state-of-the-art calibration procedures require the use of specialised calibration targets. This paper presents a novel method to extract the translation-part of the hand-eye calibration matrix with rotation-part known a priori in a target-agnostic way. Our methodology is applicable to any 2D image or 3D object as a calibration target and can also be performed in situ in the final application. The method is experimentally validated on a real robot-sensor setup with 2D and 3D targets.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge