Duanbing Chen

Multi-Task-oriented Nighttime Haze Imaging Enhancer for Vision-driven Measurement Systems

Feb 11, 2025

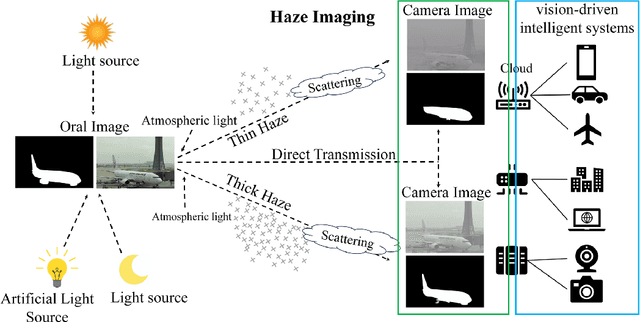

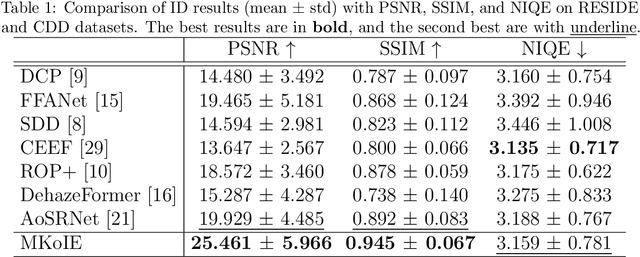

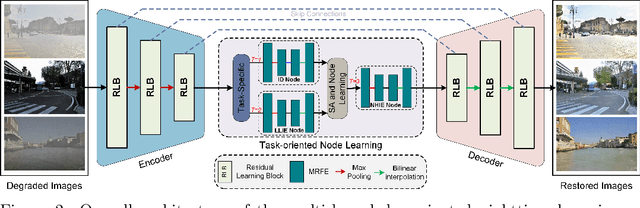

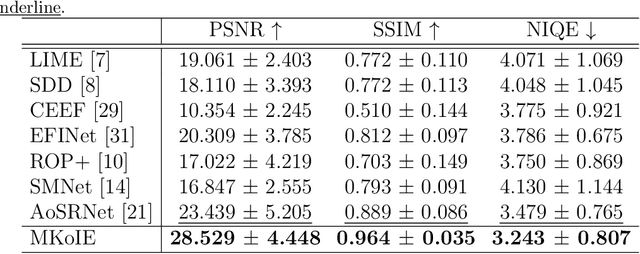

Abstract:Salient object detection (SOD) plays a critical role in vision-driven measurement systems (VMS), facilitating the detection and segmentation of key visual elements in an image. However, adverse imaging conditions such as haze during the day, low light, and haze at night severely degrade image quality, and complicating the SOD process. To address these challenges, we propose a multi-task-oriented nighttime haze imaging enhancer (MToIE), which integrates three tasks: daytime dehazing, low-light enhancement, and nighttime dehazing. The MToIE incorporates two key innovative components: First, the network employs a task-oriented node learning mechanism to handle three specific degradation types: day-time haze, low light, and night-time haze conditions, with an embedded self-attention module enhancing its performance in nighttime imaging. In addition, multi-receptive field enhancement module that efficiently extracts multi-scale features through three parallel depthwise separable convolution branches with different dilation rates, capturing comprehensive spatial information with minimal computational overhead. To ensure optimal image reconstruction quality and visual characteristics, we suggest a hybrid loss function. Extensive experiments on different types of weather/imaging conditions illustrate that MToIE surpasses existing methods, significantly enhancing the accuracy and reliability of vision systems across diverse imaging scenarios. The code is available at https://github.com/Ai-Chen-Lab/MToIE.

Identifying critical nodes in complex networks by graph representation learning

Jan 20, 2022

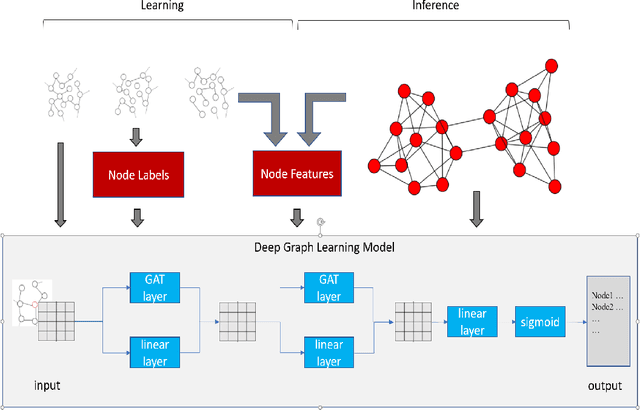

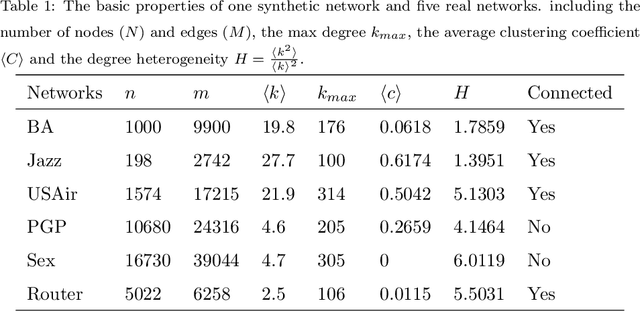

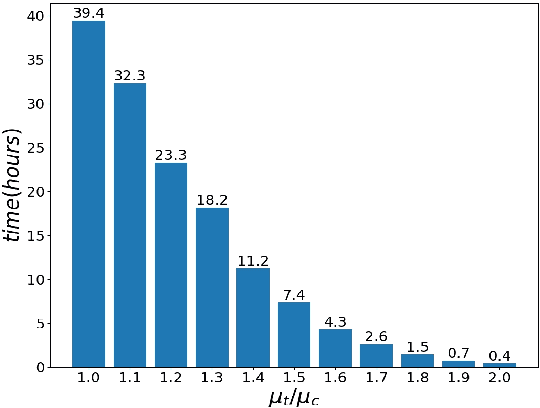

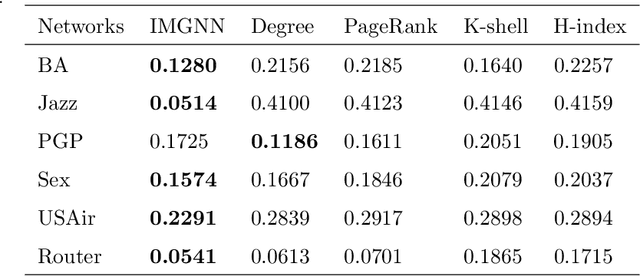

Abstract:Because of its wide application, critical nodes identification has become an important research topic at the micro level of network science. Influence maximization is one of the main problems in critical nodes mining and is usually handled with heuristics. In this paper, a deep graph learning framework IMGNN is proposed and the corresponding training sample generation scheme is designed. The framework takes centralities of nodes in a network as input and the probability that nodes in the optimal initial spreaders as output. By training on a large number of small synthetic networks, IMGNN is more efficient than human-based heuristics in minimizing the size of initial spreaders under the fixed infection scale. The experimental results on one synthetic and five real networks show that, compared with traditional non-iterative node ranking algorithms, IMGNN has the smallest proportion of initial spreaders under different infection probabilities when the final infection scale is fixed. And the reordered version of IMGNN outperforms all the latest critical nodes mining algorithms.

Pruning with Compensation: Efficient Channel Pruning for Deep Convolutional Neural Networks

Aug 31, 2021

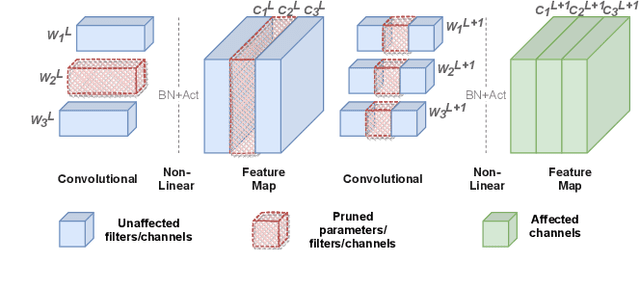

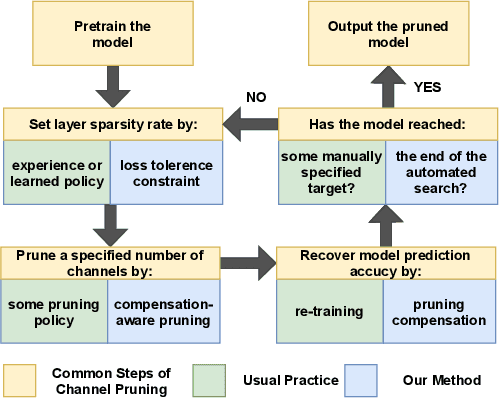

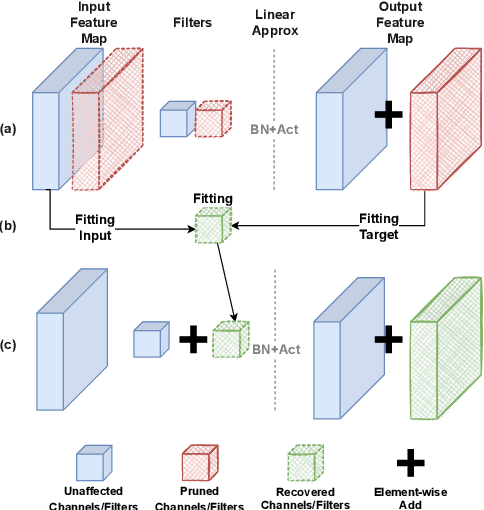

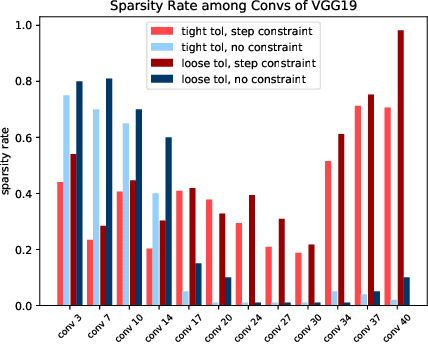

Abstract:Channel pruning is a promising technique to compress the parameters of deep convolutional neural networks(DCNN) and to speed up the inference. This paper aims to address the long-standing inefficiency of channel pruning. Most channel pruning methods recover the prediction accuracy by re-training the pruned model from the remaining parameters or random initialization. This re-training process is heavily dependent on the sufficiency of computational resources, training data, and human interference(tuning the training strategy). In this paper, a highly efficient pruning method is proposed to significantly reduce the cost of pruning DCNN. The main contributions of our method include: 1) pruning compensation, a fast and data-efficient substitute of re-training to minimize the post-pruning reconstruction loss of features, 2) compensation-aware pruning(CaP), a novel pruning algorithm to remove redundant or less-weighted channels by minimizing the loss of information, and 3) binary structural search with step constraint to minimize human interference. On benchmarks including CIFAR-10/100 and ImageNet, our method shows competitive pruning performance among the state-of-the-art retraining-based pruning methods and, more importantly, reduces the processing time by 95% and data usage by 90%.

Tool Breakage Detection using Deep Learning

Aug 16, 2018

Abstract:In manufacture, steel and other metals are mainly cut and shaped during the fabrication process by computer numerical control (CNC) machines. To keep high productivity and efficiency of the fabrication process, engineers need to monitor the real-time process of CNC machines, and the lifetime management of machine tools. In a real manufacturing process, breakage of machine tools usually happens without any indication, this problem seriously affects the fabrication process for many years. Previous studies suggested many different approaches for monitoring and detecting the breakage of machine tools. However, there still exists a big gap between academic experiments and the complex real fabrication processes such as the high demands of real-time detections, the difficulty in data acquisition and transmission. In this work, we use the spindle current approach to detect the breakage of machine tools, which has the high performance of real-time monitoring, low cost, and easy to install. We analyze the features of the current of a milling machine spindle through tools wearing processes, and then we predict the status of tool breakage by a convolutional neural network(CNN). In addition, we use a BP neural network to understand the reliability of the CNN. The results show that our CNN approach can detect tool breakage with an accuracy of 93%, while the best performance of BP is 80%.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge