Anxing Song

Tool Breakage Detection using Deep Learning

Aug 16, 2018

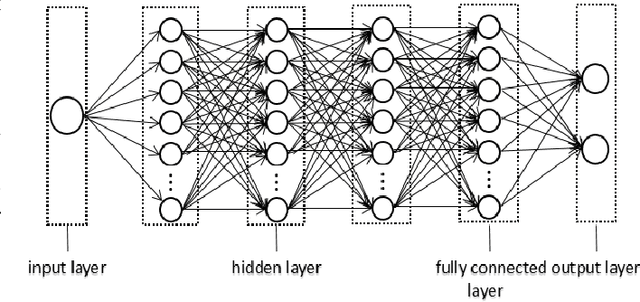

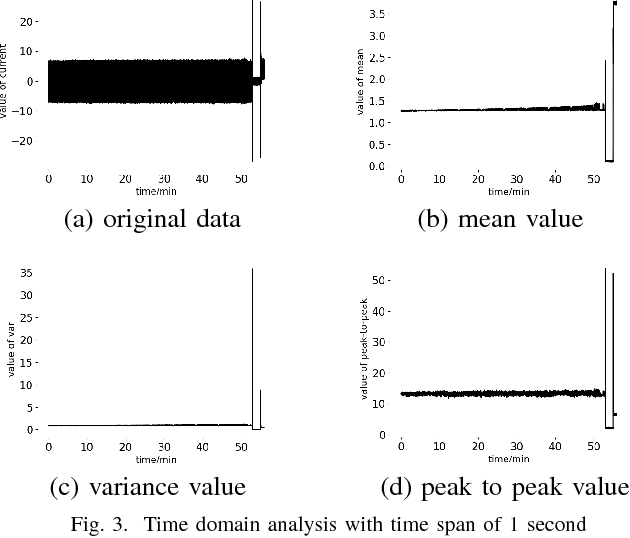

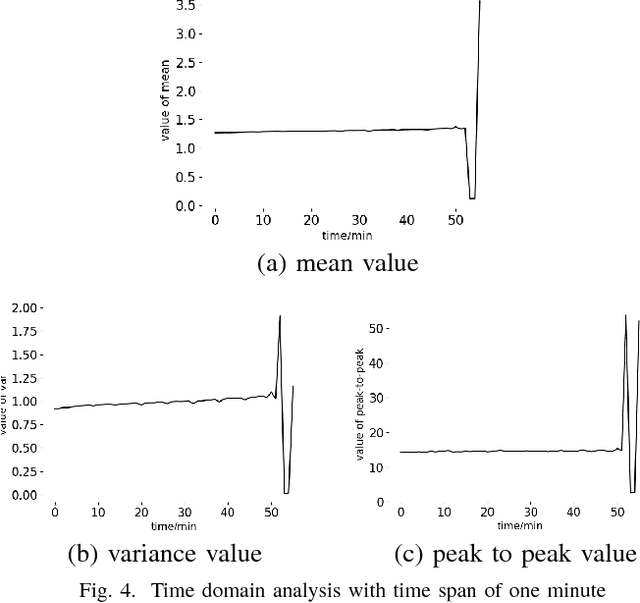

Abstract:In manufacture, steel and other metals are mainly cut and shaped during the fabrication process by computer numerical control (CNC) machines. To keep high productivity and efficiency of the fabrication process, engineers need to monitor the real-time process of CNC machines, and the lifetime management of machine tools. In a real manufacturing process, breakage of machine tools usually happens without any indication, this problem seriously affects the fabrication process for many years. Previous studies suggested many different approaches for monitoring and detecting the breakage of machine tools. However, there still exists a big gap between academic experiments and the complex real fabrication processes such as the high demands of real-time detections, the difficulty in data acquisition and transmission. In this work, we use the spindle current approach to detect the breakage of machine tools, which has the high performance of real-time monitoring, low cost, and easy to install. We analyze the features of the current of a milling machine spindle through tools wearing processes, and then we predict the status of tool breakage by a convolutional neural network(CNN). In addition, we use a BP neural network to understand the reliability of the CNN. The results show that our CNN approach can detect tool breakage with an accuracy of 93%, while the best performance of BP is 80%.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge