Caitlin Mueller

Cooperative Task and Motion Planning for Multi-Arm Assembly Systems

Mar 04, 2022

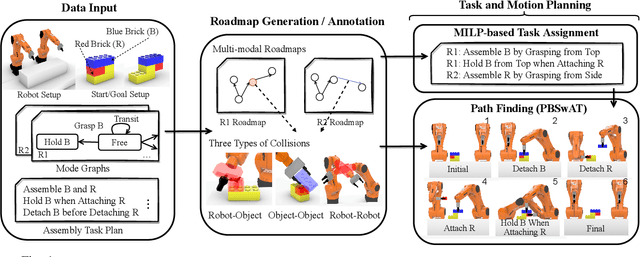

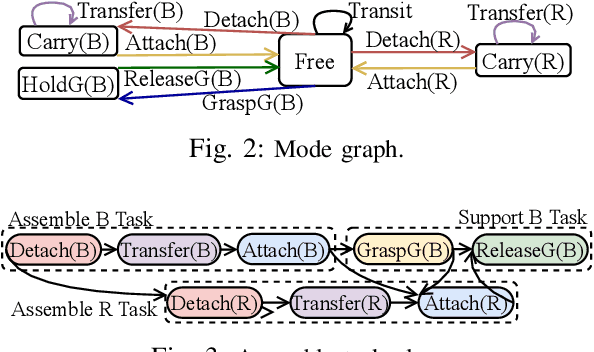

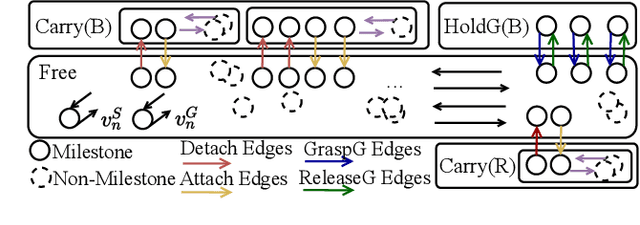

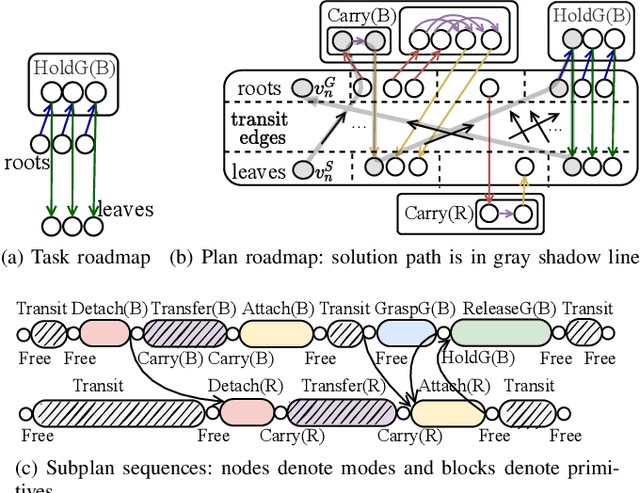

Abstract:Multi-robot assembly systems are becoming increasingly appealing in manufacturing due to their ability to automatically, flexibly, and quickly construct desired structural designs. However, effectively planning for these systems in a manner that ensures each robot is simultaneously productive, and not idle, is challenging due to (1) the close proximity that the robots must operate in to manipulate the structure and (2) the inherent structural partial orderings on when each part can be installed. In this paper, we present a task and motion planning framework that jointly plans safe, low-makespan plans for a team of robots to assemble complex spatial structures. Our framework takes a hierarchical approach that, at the high level, uses Mixed-integer Linear Programs to compute an abstract plan comprised of an allocation of robots to tasks subject to precedence constraints and, at the low level, builds on a state-of-the-art algorithm for Multi-Agent Path Finding to plan collision-free robot motions that realize this abstract plan. Critical to our approach is the inclusion of certain collision constraints and movement durations during high-level planning, which better informs the search for abstract plans that are likely to be both feasible and low-makespan while keeping the search tractable. We demonstrate our planning system on several challenging assembly domains with several (sometimes heterogeneous) robots with grippers or suction plates for assembling structures with up to 23 objects involving Lego bricks, bars, plates, or irregularly shaped blocks.

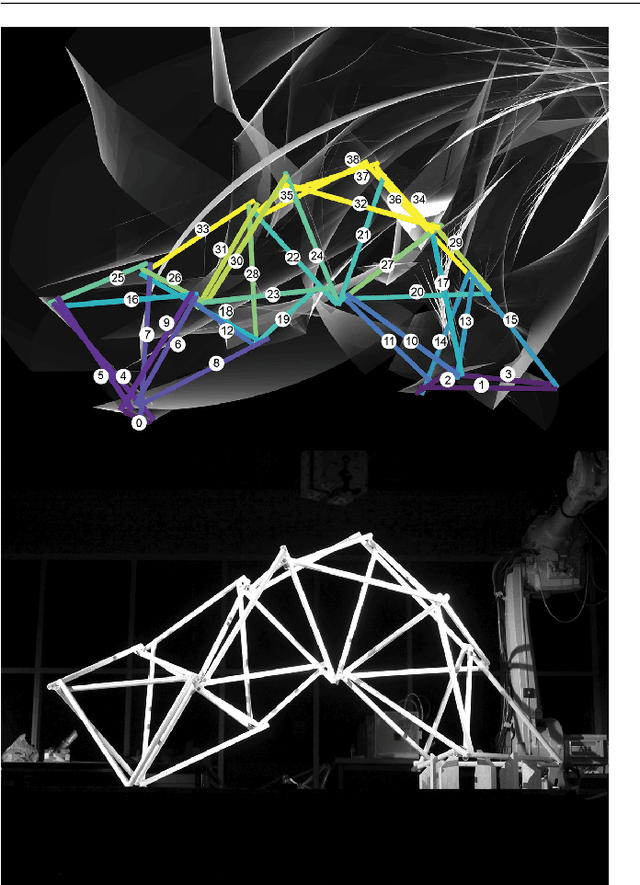

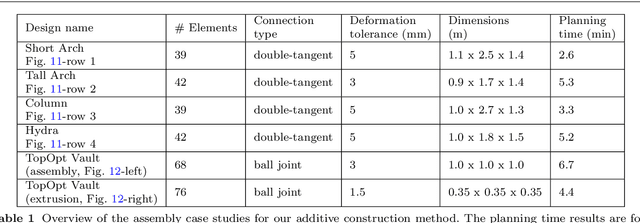

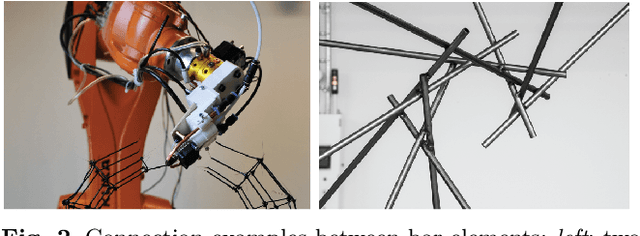

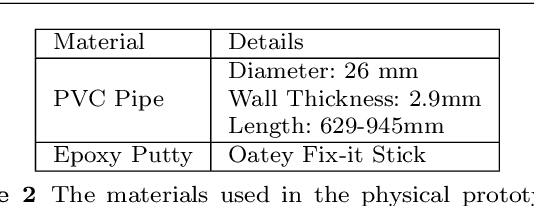

Robotic additive construction of bar structures: Unified sequence and motion planning

May 24, 2021

Abstract:Additive robotic construction of building-scale discrete bar structures, such as trusses and space frames, is increasingly attractive due to the potential improvements in efficiency, safety, and design possibilities. However, programming complex robots, such as manipulators with seven degrees of freedom, to successfully complete construction tasks can be tedious, challenging, or impossible for a human to do manually. Namely, the structure must be constructed in a sequence that preserves structural properties, such as stiffness, at each step. At the same time, this sequence must allow for the robot to precisely manipulate elements within the in-progress structure while respecting geometric constraints that, for example, ensure the robot does not collide with what it has built. In this work, we present an automated and newly generalized planning approach for jointly finding a construction sequence and robot motion plan for additive construction that satisfies these requirements. Our approach can be applied in a variety of additive construction processes, and we demonstrate it specifically on spatial extrusion and discrete bar assembly in this paper. We demonstrate the effectiveness of our approach on several simulated and real-world extrusion and assembly tasks, including a human-scale physical prototype, for which our algorithm is deployed for the first time to plan the assembly of a complicated double tangent bar system design.

SimJEB: Simulated Jet Engine Bracket Dataset

May 07, 2021

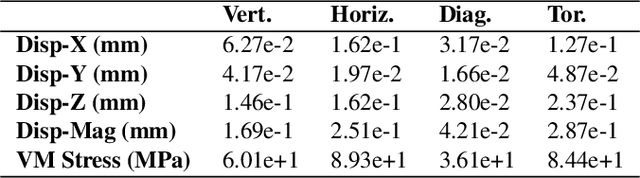

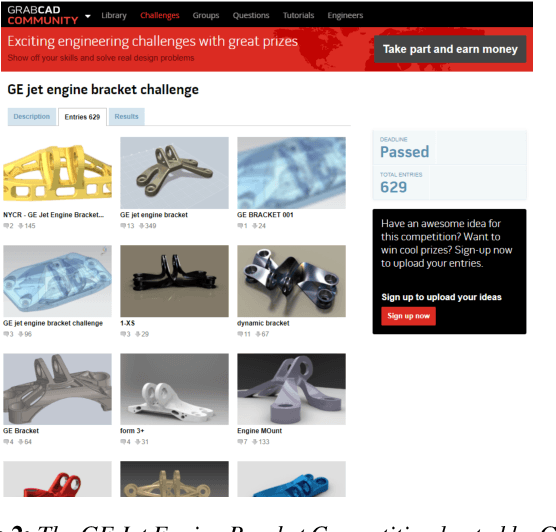

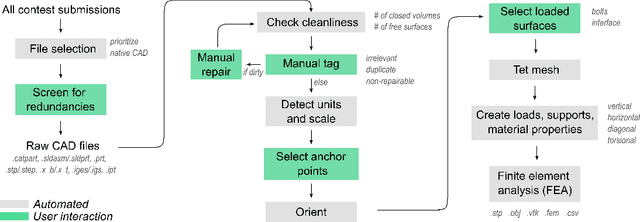

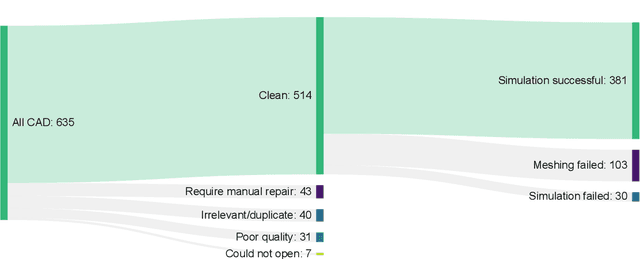

Abstract:Recent advancements in geometric deep learning have enabled a new class of engineering surrogate models; however, few existing shape datasets are well-suited to evaluate them. This paper introduces the Simulated Jet Engine Bracket Dataset (SimJEB): a new, public collection of crowdsourced mechanical brackets and high-fidelity structural simulations designed specifically for surrogate modeling. SimJEB models are more complex, diverse, and realistic than the synthetically generated datasets commonly used in parametric surrogate model evaluation. In contrast to existing engineering shape collections, SimJEB's models are all designed for the same engineering function and thus have consistent structural loads and support conditions. The models in SimJEB were collected from the original submissions to the GrabCAD Jet Engine Bracket Challenge: an open engineering design competition with over 700 hand-designed CAD entries from 320 designers representing 56 countries. Each model has been cleaned, categorized, meshed, and simulated with finite element analysis according to the original competition specifications. The result is a collection of diverse, high-quality and application-focused designs for advancing geometric deep learning and engineering surrogate models.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge