Adriana Schulz

Towards Autonomous Sustainability Assessment via Multimodal AI Agents

Jul 22, 2025Abstract:Interest in sustainability information has surged in recent years. However, the data required for a life cycle assessment (LCA) that maps the materials and processes from product manufacturing to disposal into environmental impacts (EI) are often unavailable. Here we reimagine conventional LCA by introducing multimodal AI agents that emulate interactions between LCA experts and stakeholders like product managers and engineers to calculate the cradle-to-gate (production) carbon emissions of electronic devices. The AI agents iteratively generate a detailed life-cycle inventory leveraging a custom data abstraction and software tools that extract information from online text and images from repair communities and government certifications. This approach reduces weeks or months of expert time to under one minute and closes data availability gaps while yielding carbon footprint estimates within 19% of expert LCAs with zero proprietary data. Additionally, we develop a method to directly estimate EI by comparing an input to a cluster of products with similar descriptions and known carbon footprints. This runs in 3 ms on a laptop with a MAPE of 12.28% on electronic products. Further, we develop a data-driven method to generate emission factors. We use the properties of an unknown material to represent it as a weighted sum of emission factors for similar materials. Compared to human experts picking the closest LCA database entry, this improves MAPE by 120.26%. We analyze the data and compute scaling of this approach and discuss its implications for future LCA workflows.

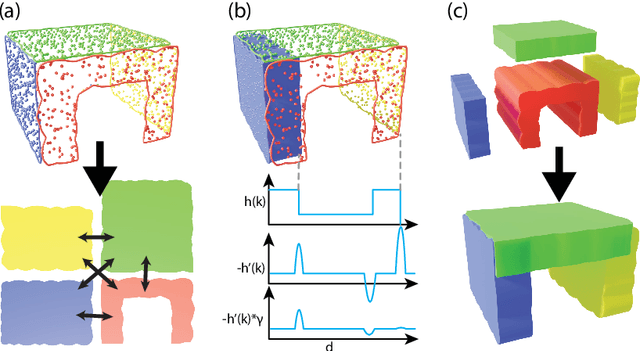

View2CAD: Reconstructing View-Centric CAD Models from Single RGB-D Scans

Apr 05, 2025

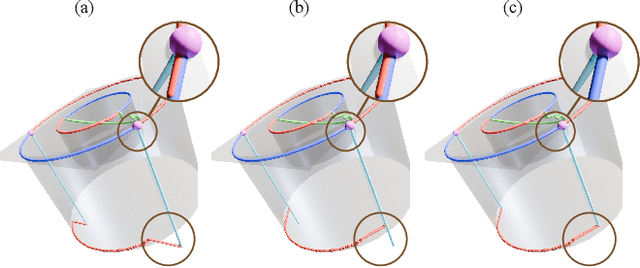

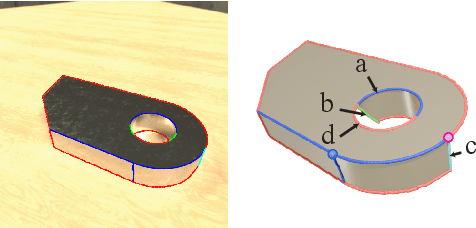

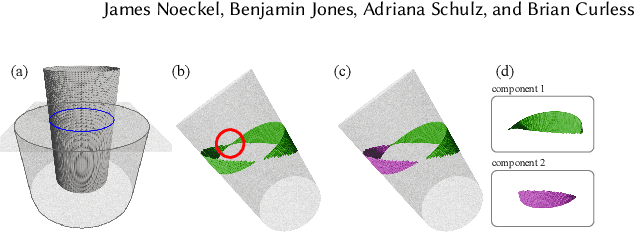

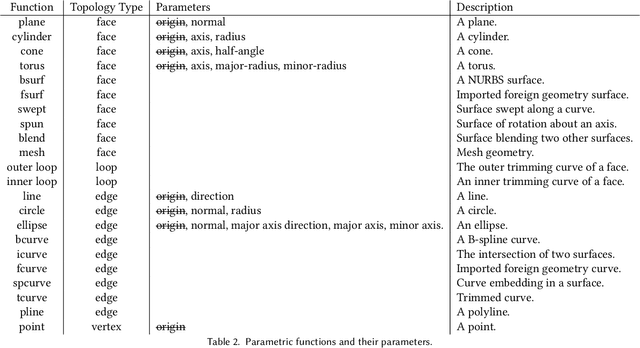

Abstract:Parametric CAD models, represented as Boundary Representations (B-reps), are foundational to modern design and manufacturing workflows, offering the precision and topological breakdown required for downstream tasks such as analysis, editing, and fabrication. However, B-Reps are often inaccessible due to conversion to more standardized, less expressive geometry formats. Existing methods to recover B-Reps from measured data require complete, noise-free 3D data, which are laborious to obtain. We alleviate this difficulty by enabling the precise reconstruction of CAD shapes from a single RGB-D image. We propose a method that addresses the challenge of reconstructing only the observed geometry from a single view. To allow for these partial observations, and to avoid hallucinating incorrect geometry, we introduce a novel view-centric B-rep (VB-Rep) representation, which incorporates structures to handle visibility limits and encode geometric uncertainty. We combine panoptic image segmentation with iterative geometric optimization to refine and improve the reconstruction process. Our results demonstrate high-quality reconstruction on synthetic and real RGB-D data, showing that our method can bridge the reality gap.

Zero-shot Sequential Neuro-symbolic Reasoning for Automatically Generating Architecture Schematic Designs

Jan 25, 2024Abstract:This paper introduces a novel automated system for generating architecture schematic designs aimed at streamlining complex decision-making at the multifamily real estate development project's outset. Leveraging the combined strengths of generative AI (neuro reasoning) and mathematical program solvers (symbolic reasoning), the method addresses both the reliance on expert insights and technical challenges in architectural schematic design. To address the large-scale and interconnected nature of design decisions needed for designing a whole building, we proposed a novel sequential neuro-symbolic reasoning approach, emulating traditional architecture design processes from initial concept to detailed layout. To remove the need to hand-craft a cost function to approximate the desired objectives, we propose a solution that uses neuro reasoning to generate constraints and cost functions that the symbolic solvers can use to solve. We also incorporate feedback loops for each design stage to ensure a tight integration between neuro and symbolic reasoning. Developed using GPT-4 without further training, our method's effectiveness is validated through comparative studies with real-world buildings. Our method can generate various building designs in accordance with the understanding of the neighborhood, showcasing its potential to transform the realm of architectural schematic design.

How Can Large Language Models Help Humans in Design and Manufacturing?

Jul 25, 2023Abstract:The advancement of Large Language Models (LLMs), including GPT-4, provides exciting new opportunities for generative design. We investigate the application of this tool across the entire design and manufacturing workflow. Specifically, we scrutinize the utility of LLMs in tasks such as: converting a text-based prompt into a design specification, transforming a design into manufacturing instructions, producing a design space and design variations, computing the performance of a design, and searching for designs predicated on performance. Through a series of examples, we highlight both the benefits and the limitations of the current LLMs. By exposing these limitations, we aspire to catalyze the continued improvement and progression of these models.

Computational Design of Passive Grippers

Jun 05, 2023

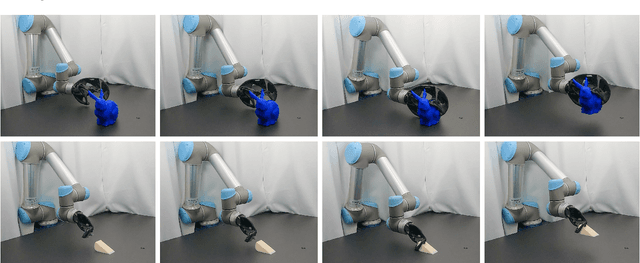

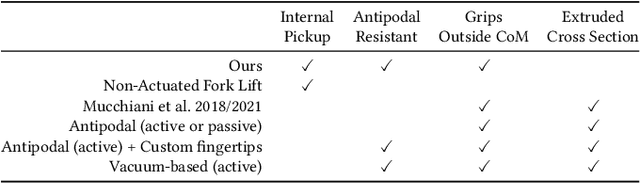

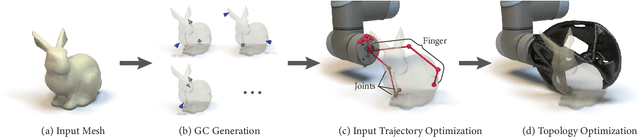

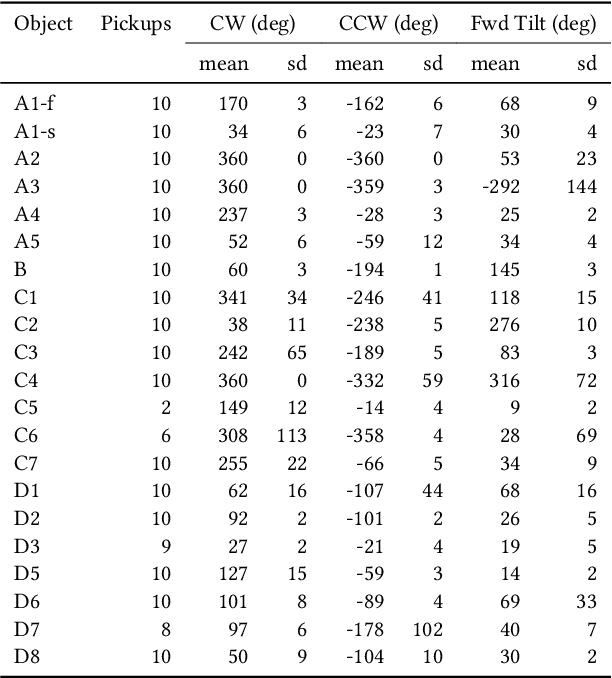

Abstract:This work proposes a novel generative design tool for passive grippers -- robot end effectors that have no additional actuation and instead leverage the existing degrees of freedom in a robotic arm to perform grasping tasks. Passive grippers are used because they offer interesting trade-offs between cost and capabilities. However, existing designs are limited in the types of shapes that can be grasped. This work proposes to use rapid-manufacturing and design optimization to expand the space of shapes that can be passively grasped. Our novel generative design algorithm takes in an object and its positioning with respect to a robotic arm and generates a 3D printable passive gripper that can stably pick the object up. To achieve this, we address the key challenge of jointly optimizing the shape and the insert trajectory to ensure a passively stable grasp. We evaluate our method on a testing suite of 22 objects (23 experiments), all of which were evaluated with physical experiments to bridge the virtual-to-real gap. Code and data are at https://homes.cs.washington.edu/~milink/passive-gripper/

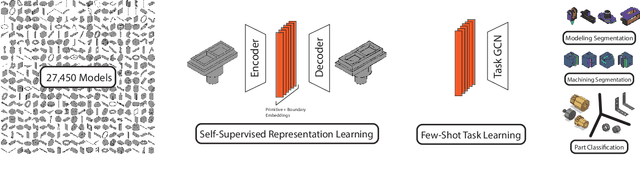

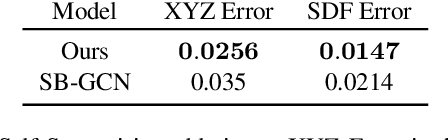

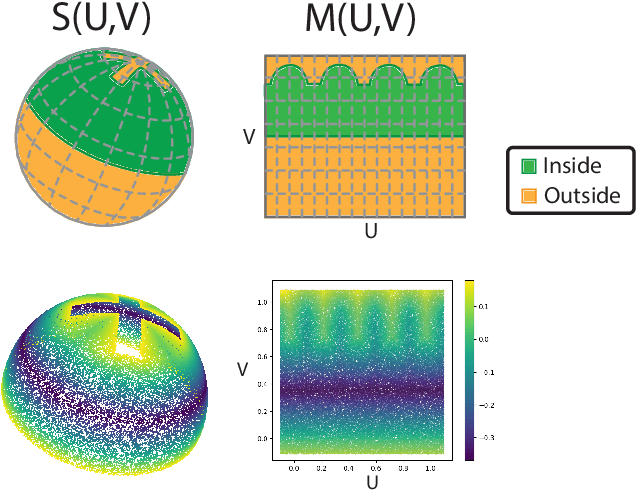

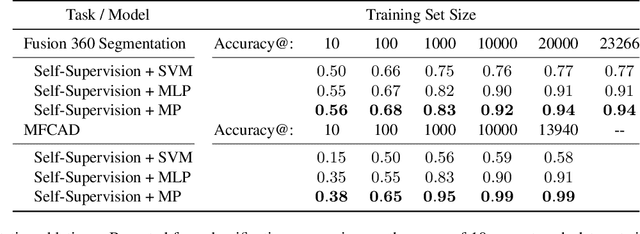

Self-Supervised Representation Learning for CAD

Oct 19, 2022

Abstract:The design of man-made objects is dominated by computer aided design (CAD) tools. Assisting design with data-driven machine learning methods is hampered by lack of labeled data in CAD's native format; the parametric boundary representation (B-Rep). Several data sets of mechanical parts in B-Rep format have recently been released for machine learning research. However, large scale databases are largely unlabeled, and labeled datasets are small. Additionally, task specific label sets are rare, and costly to annotate. This work proposes to leverage unlabeled CAD geometry on supervised learning tasks. We learn a novel, hybrid implicit/explicit surface representation for B-Rep geometry, and show that this pre-training significantly improves few-shot learning performance and also achieves state-of-the-art performance on several existing B-Rep benchmarks.

Mates2Motion: Learning How Mechanical CAD Assemblies Work

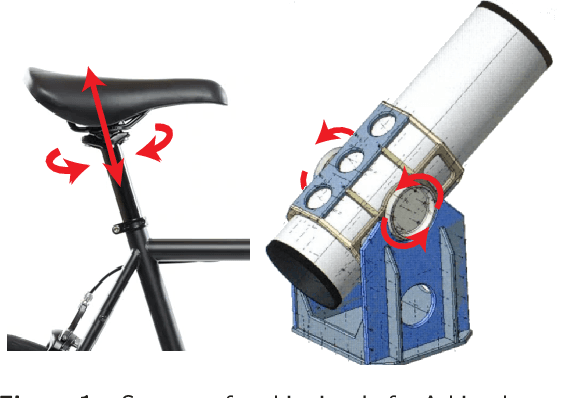

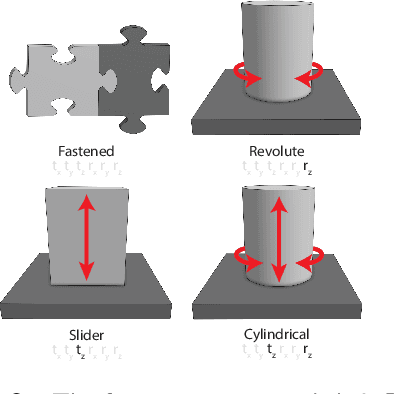

Aug 02, 2022

Abstract:We describe our work on inferring the degrees of freedom between mated parts in mechanical assemblies using deep learning on CAD representations. We train our model using a large dataset of real-world mechanical assemblies consisting of CAD parts and mates joining them together. We present methods for re-defining these mates to make them better reflect the motion of the assembly, as well as narrowing down the possible axes of motion. We also conduct a user study to create a motion-annotated test set with more reliable labels.

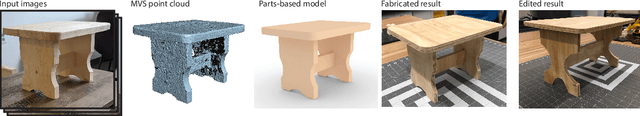

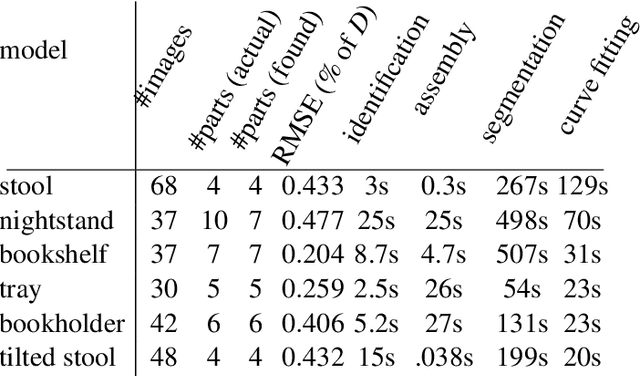

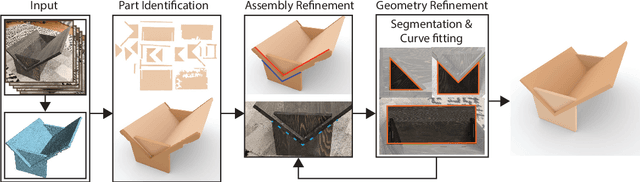

Fabrication-Aware Reverse Engineering for Carpentry

Jul 21, 2021

Abstract:We propose a novel method to generate fabrication blueprints from images of carpentered items. While 3D reconstruction from images is a well-studied problem, typical approaches produce representations that are ill-suited for computer-aided design and fabrication applications. Our key insight is that fabrication processes define and constrain the design space for carpentered objects, and can be leveraged to develop novel reconstruction methods. Our method makes use of domain-specific constraints to recover not just valid geometry, but a semantically valid assembly of parts, using a combination of image-based and geometric optimization techniques. We demonstrate our method on a variety of wooden objects and furniture, and show that we can automatically obtain designs that are both easy to edit and accurate recreations of the ground truth. We further illustrate how our method can be used to fabricate a physical replica of the captured object as well as a customized version, which can be produced by directly editing the reconstructed model in CAD software.

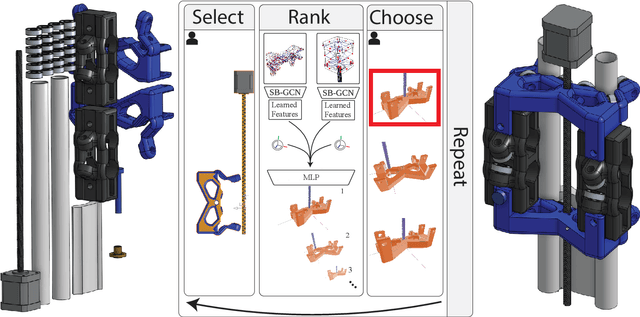

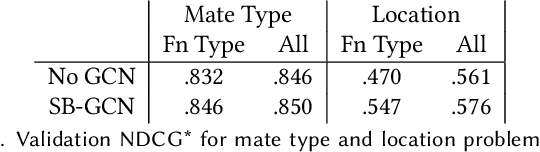

SB-GCN: Structured BREP Graph Convolutional Network for Automatic Mating of CAD Assemblies

May 25, 2021

Abstract:Assembly modeling is a core task of computer aided design (CAD), comprising around one third of the work in a CAD workflow. Optimizing this process therefore represents a huge opportunity in the design of a CAD system, but current research of assembly based modeling is not directly applicable to modern CAD systems because it eschews the dominant data structure of modern CAD: parametric boundary representations (BREPs). CAD assembly modeling defines assemblies as a system of pairwise constraints, called mates, between parts, which are defined relative to BREP topology rather than in world coordinates common to existing work. We propose SB-GCN, a representation learning scheme on BREPs that retains the topological structure of parts, and use these learned representations to predict CAD type mates. To train our system, we compiled the first large scale dataset of BREP CAD assemblies, which we are releasing along with benchmark mate prediction tasks. Finally, we demonstrate the compatibility of our model with an existing commercial CAD system by building a tool that assists users in mate creation by suggesting mate completions, with 72.2% accuracy.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge