Multi-Wheeled Passive Sliding with Fully-Actuated Aerial Robots: Tip-Over Recovery and Avoidance

Paper and Code

May 29, 2024

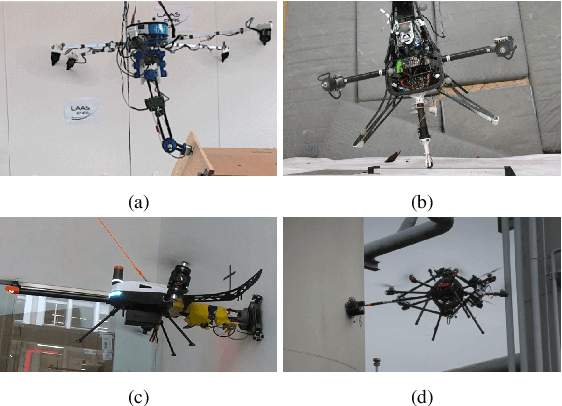

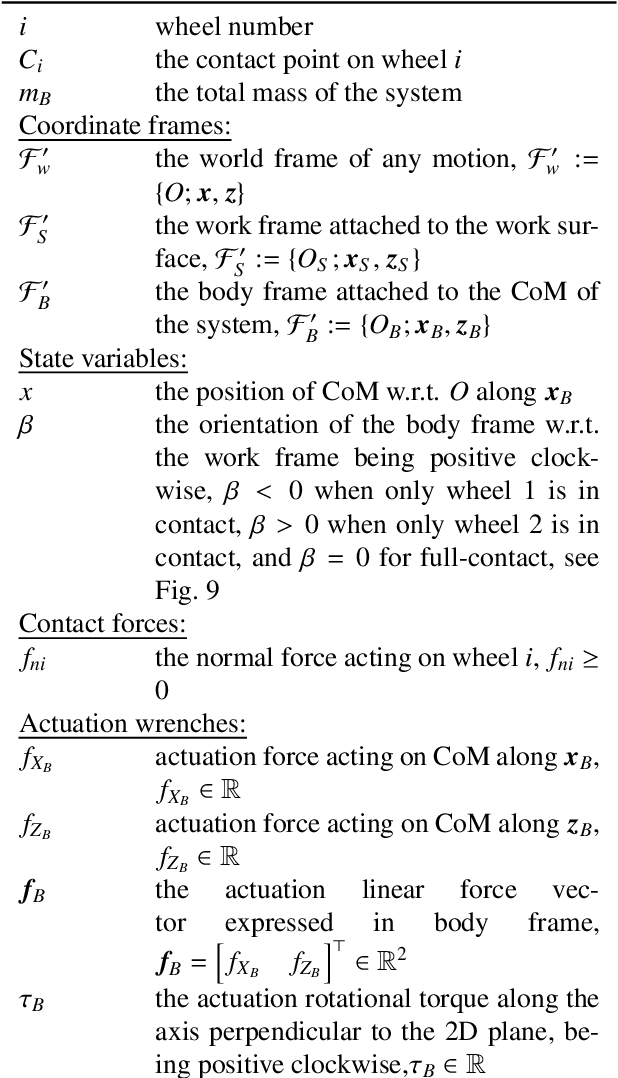

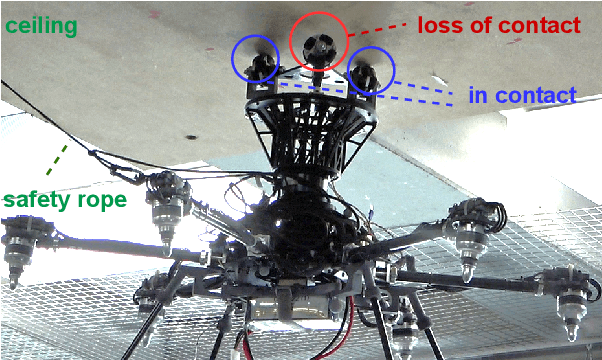

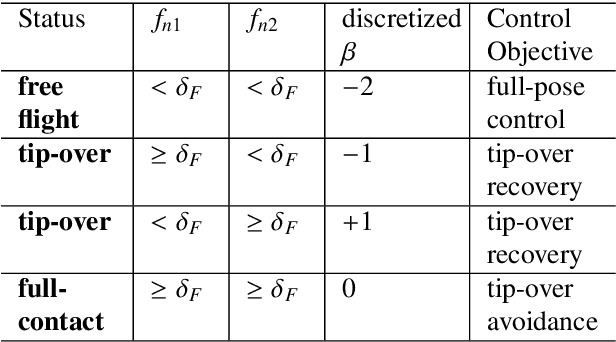

Push-and-slide tasks carried out by fully-actuated aerial robots can be used for inspection and simple maintenance tasks at height, such as non-destructive testing and painting. Often, an end-effector based on multiple non-actuated contact wheels is used to contact the surface. This approach entails challenges in ensuring consistent wheel contact with a surface whose exact orientation and location might be uncertain due to sensor aliasing and drift. Using a standard full-pose controller dependent on the inaccurate surface position and orientation may cause wheels to lose contact during sliding, and subsequently lead to robot tip-over. To address the tip-over issue, we present two approaches: (1) tip-over avoidance guidelines for hardware design, and (2) control for tip-over recovery and avoidance. Physical experiments with a fully-actuated aerial vehicle were executed for a push-and-slide task on a flat surface. The resulting data is used in deriving tip-over avoidance guidelines and designing a simulator that closely captures real-world conditions. We then use the simulator to test the effectiveness and robustness of the proposed approaches in risky scenarios against uncertainties.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge