Yingjun Tian

Function based sim-to-real learning for shape control of deformable free-form surfaces

May 14, 2024

Abstract:For the shape control of deformable free-form surfaces, simulation plays a crucial role in establishing the mapping between the actuation parameters and the deformed shapes. The differentiation of this forward kinematic mapping is usually employed to solve the inverse kinematic problem for determining the actuation parameters that can realize a target shape. However, the free-form surfaces obtained from simulators are always different from the physically deformed shapes due to the errors introduced by hardware and the simplification adopted in physical simulation. To fill the gap, we propose a novel deformation function based sim-to-real learning method that can map the geometric shape of a simulated model into its corresponding shape of the physical model. Unlike the existing sim-to-real learning methods that rely on completely acquired dense markers, our method accommodates sparsely distributed markers and can resiliently use all captured frames -- even for those in the presence of missing markers. To demonstrate its effectiveness, our sim-to-real method has been integrated into a neural network-based computational pipeline designed to tackle the inverse kinematic problem on a pneumatically actuated deformable mannequin.

OpenPneu: Compact platform for pneumatic actuation with multi-channels

Sep 22, 2022

Abstract:This paper presents a compact system, OpenPneu, to support the pneumatic actuation for multi-chambers on soft robots. Micro-pumps are employed in the system to generate airflow and therefore no extra input as compressed air is needed. Our system conducts modular design to provide good scalability, which has been demonstrated on a prototype with ten air channels. Each air channel of OpenPneu is equipped with both the inflation and the deflation functions to provide a full range pressure supply from positive to negative with a maximal flow rate at 1.7 L/min. High precision closed-loop control of pressures has been built into our system to achieve stable and efficient dynamic performance in actuation. An open-source control interface and API in Python are provided. We also demonstrate the functionality of OpenPneu on three soft robotic systems with up to 10 chambers.

Optimizing out-of-plane stiffness for soft grippers

Jul 19, 2022

Abstract:In this paper, we presented a data-driven framework to optimize the out-of-plane stiffness for soft grippers to achieve mechanical properties as hard-to-twist and easy-to-bend. The effectiveness of this method is demonstrated in the design of a soft pneumatic bending actuator (SPBA). First, a new objective function is defined to quantitatively evaluate the out-of-plane stiffness as well as the bending performance. Then, sensitivity analysis is conducted on the parametric model of an SPBA design to determine the optimized design parameters with the help of Finite Element Analysis (FEA). To enable the computation of numerical optimization, a data-driven approach is employed to learn a cost function that directly represents the out-of-plane stiffness as a differentiable function of the design variables. A gradient-based method is used to maximize the out-of-plane stiffness of the SPBA while ensuring specific bending performance. The effectiveness of our method has been demonstrated in physical experiments taken on 3D-printed grippers.

Soft Robotic Mannequin: Design and Algorithm for Deformation Control

May 23, 2022

Abstract:This paper presents a novel soft robotic system for a deformable mannequin that can be employed to physically realize the 3D geometry of different human bodies. The soft membrane on a mannequin is deformed by inflating several curved chambers using pneumatic actuation. Controlling the freeform surface of a soft membrane by adjusting the pneumatic actuation in different chambers is challenging as the membrane's shape is commonly determined by the interaction between all chambers. Using vision feedback provided by a structured-light based 3D scanner, we developed an efficient algorithm to compute the optimized actuation of all chambers which could drive the soft membrane to deform into the best approximation of different target shapes. Our algorithm converges quickly by including pose estimation in the loop of optimization. The time-consuming step of evaluating derivatives on the deformable membrane is avoided by using the Broyden update when possible. The effectiveness of our soft robotic mannequin with controlled deformation has been verified in experiments.

Collision-Aware Fast Simulation for Soft Robots by Optimization-Based Geometric Computing

Mar 03, 2022

Abstract:Soft robots are able to safely interact with environments because of their mechanical compliance. Self-collision is also employed in the modern design of soft robots to enhance their performance in different tasks. However, developing an efficient and reliable simulator which can handle the collision response well, is still a challenging task in the research of soft robotics. This paper presents a collision-aware simulator based on geometric optimization, in which we develop a highly efficient and realistic collision checking / response model incorporating a hyperelastic material property. Both actuated deformation and collision response for soft robots are formulated as geometry-based objectives. The collision-free body of a soft robot can be obtained by minimizing the geometry-based objective function. Different from the FEA-based physical simulation, the proposed pipeline performs a much lower computational cost. Moreover, adaptive remeshing is applied to achieve the improvement of the convergence when dealing with soft robots having large volume variations. Experimental tests are conducted on different soft robots to verify the performance of our approach.

Singularity-aware motion planning for multi-axis additive manufacturing

Feb 27, 2021

Abstract:Multi-axis additive manufacturing enables high flexibility of material deposition along dynamically varied directions. The Cartesian motion platforms of these machines include three parallel axes and two rotational axes. Singularity on rotational axes is a critical issue to be tackled in motion planning for ensuring high quality of manufacturing results. The highly nonlinear mapping in the singular region can convert a smooth toolpath with uniformly sampled waypoints defined in the model coordinate system into a highly discontinuous motion in the machine coordinate system, which leads to over-extrusion / under-extrusion of materials in filament-based additive manufacturing. Moreover, collision may occur when sampling-based collision avoidance is employed. In this paper, we present a motion planning method to support the manufacturing realization of designed toolpaths for multi-axis additive manufacturing. Problems of singularity and collision are considered in an integrated manner to improve the motion therefore the quality of fabrication. Experiments are conducted to demonstrate the performance of our method.

Jacobian-based learning for inverse kinematics of soft robots

Dec 27, 2020

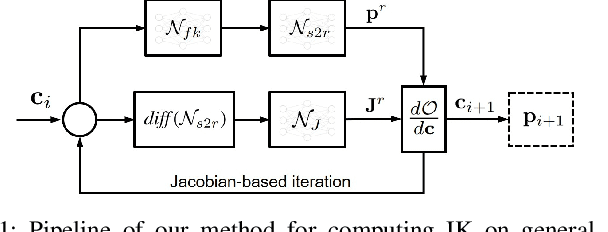

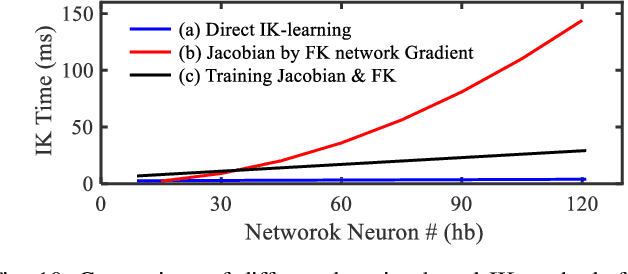

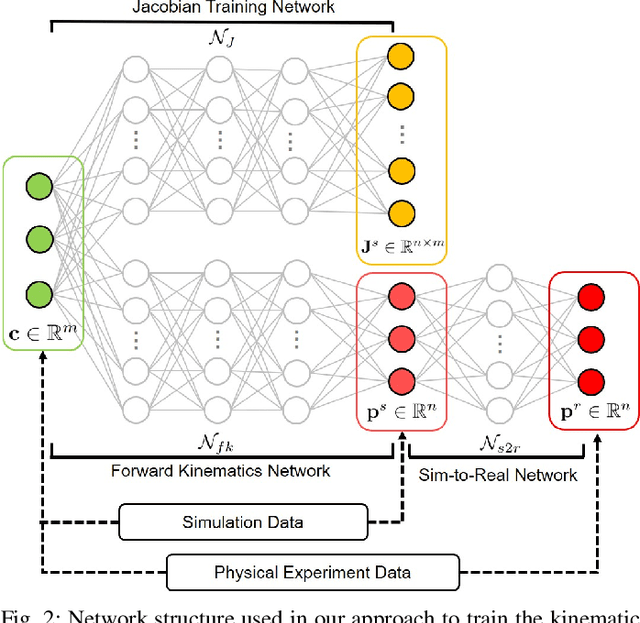

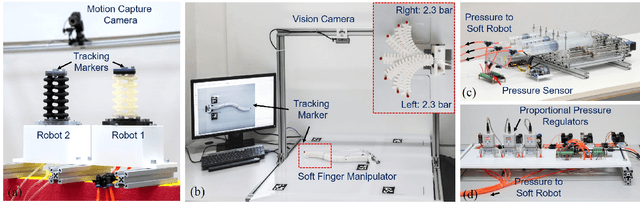

Abstract:This paper presents a new method to solve the inverse kinematic (IK) problem in real-time on soft robots with highly non-linear deformation. The major challenge of efficiently computing IK for such robots is caused by the lack of analytical formulation for either forward or inverse kinematics. To tackle this challenge, we employ neural-networks to learn both the mapping function of forward kinematics and also the Jacobian of this function. As a result, Jacobian-based iteration can be applied to solve the IK problem. A sim-to-real training transfer strategy is conducted to make this approach more practical. We first generate large amount of samples in a simulation environment for learning both the kinematic and the Jacobian networks of a soft robot design. After that, a sim-to-real layer of differentiable neurons is employed to map the results of simulation to the physical hardware, where this sim-to-real layer can be learned from very limited number of training samples generated on the hardware. The effectiveness of our approach has been verified on several pneumatic-driven soft robots in the tasks of trajectory following and interactive positioning.

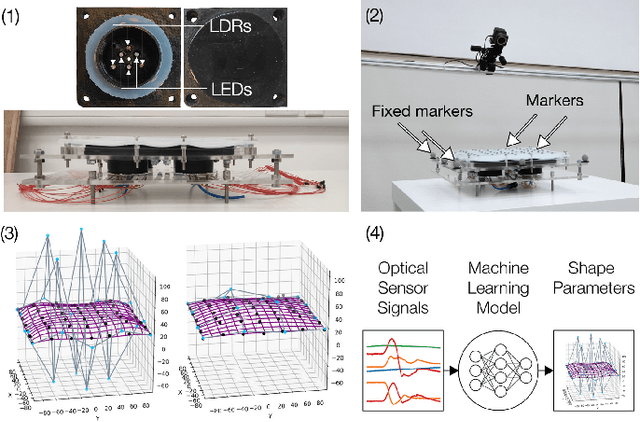

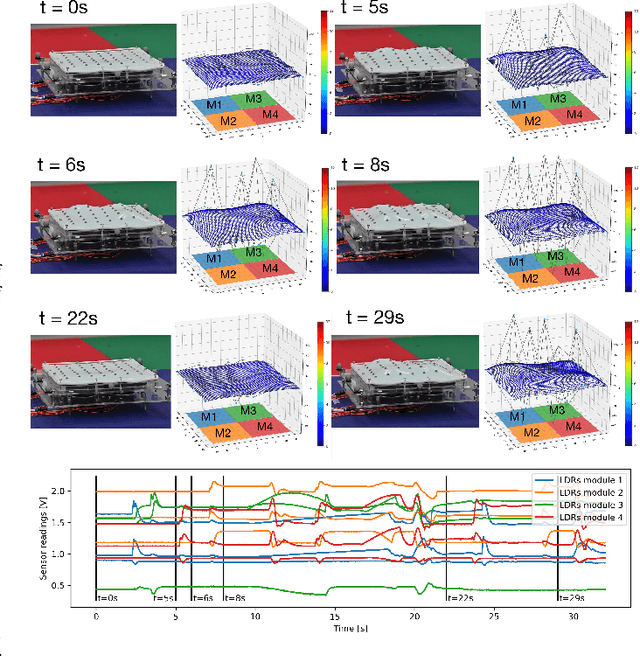

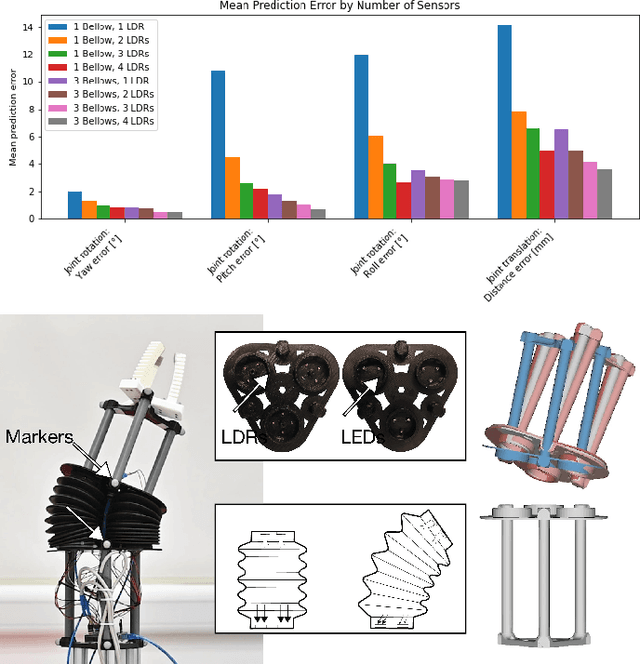

Sensing and Reconstruction of 3D Deformation on Pneumatic Soft Robots

Dec 22, 2020

Abstract:Real-time proprioception is a challenging problem for soft robots, which have almost infinite degrees-of-freedom in body deformation. When multiple actuators are used, it becomes more difficult as deformation can also occur on actuators caused by interaction between each other. To tackle this problem, we present a method in this paper to sense and reconstruct 3D deformation on pneumatic soft robots by first integrating multiple low-cost sensors inside the chambers of pneumatic actuators and then using machine learning to convert the captured signals into shape parameters of soft robots. An exterior motion capture system is employed to generate the datasets for both training and testing. With the help of good shape parameterization, the 3D shape of a soft robot can be accurately reconstructed from signals obtained from multiple sensors. We demonstrate the effectiveness of this approach on two designs of soft robots -- a robotic joint and a deformable membrane. After parameterizing the deformation of these soft robots into compact shape parameters, we can effectively train the neural networks to reconstruct the 3D deformation from the sensor signals. The sensing and shape prediction pipeline can run at 50Hz in real-time on a consumer-level device.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge