Jo M. P. Geraedts

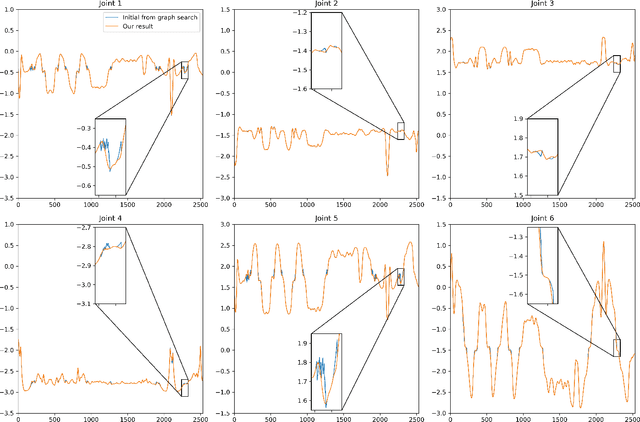

Jacobian-based learning for inverse kinematics of soft robots

Dec 27, 2020

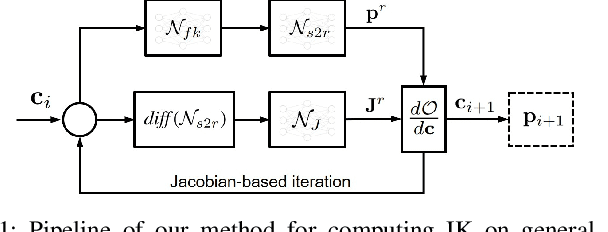

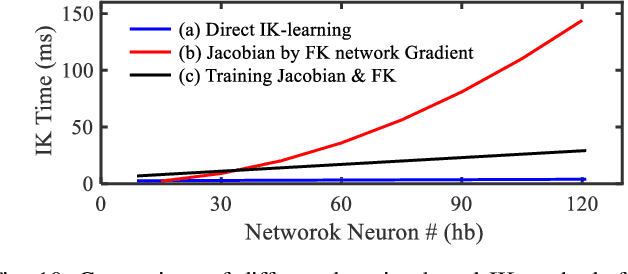

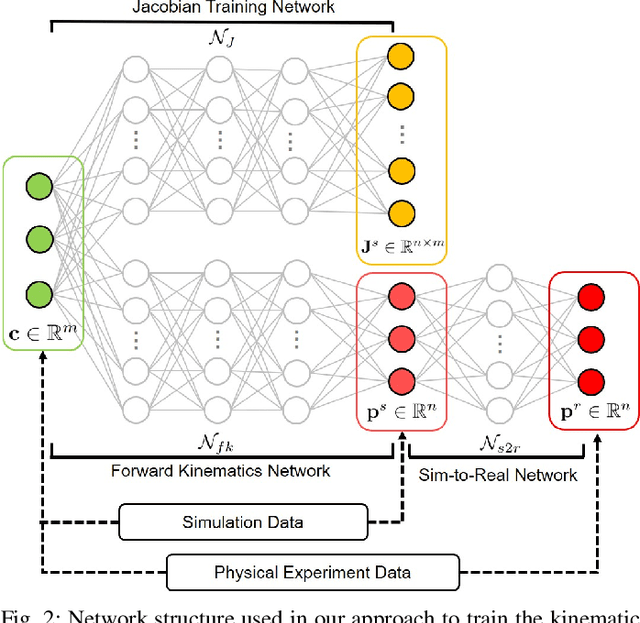

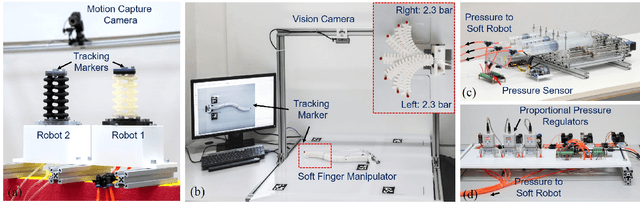

Abstract:This paper presents a new method to solve the inverse kinematic (IK) problem in real-time on soft robots with highly non-linear deformation. The major challenge of efficiently computing IK for such robots is caused by the lack of analytical formulation for either forward or inverse kinematics. To tackle this challenge, we employ neural-networks to learn both the mapping function of forward kinematics and also the Jacobian of this function. As a result, Jacobian-based iteration can be applied to solve the IK problem. A sim-to-real training transfer strategy is conducted to make this approach more practical. We first generate large amount of samples in a simulation environment for learning both the kinematic and the Jacobian networks of a soft robot design. After that, a sim-to-real layer of differentiable neurons is employed to map the results of simulation to the physical hardware, where this sim-to-real layer can be learned from very limited number of training samples generated on the hardware. The effectiveness of our approach has been verified on several pneumatic-driven soft robots in the tasks of trajectory following and interactive positioning.

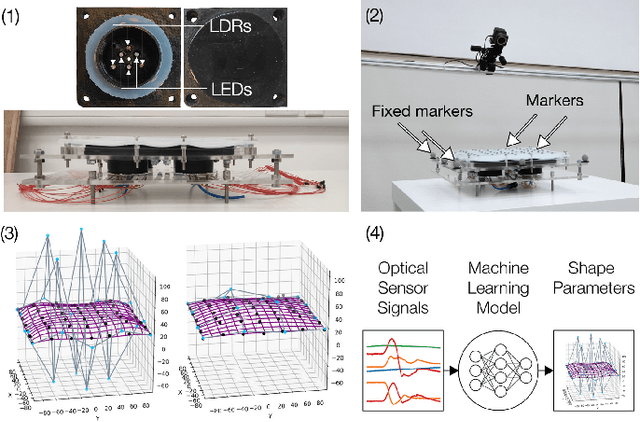

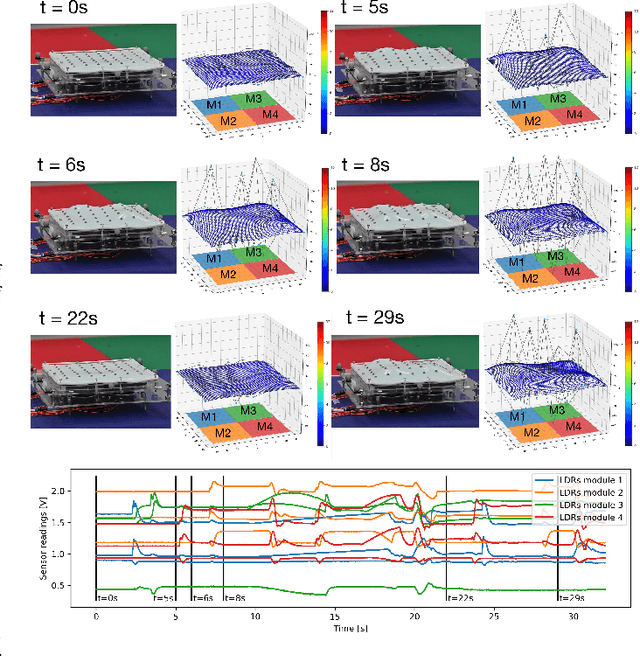

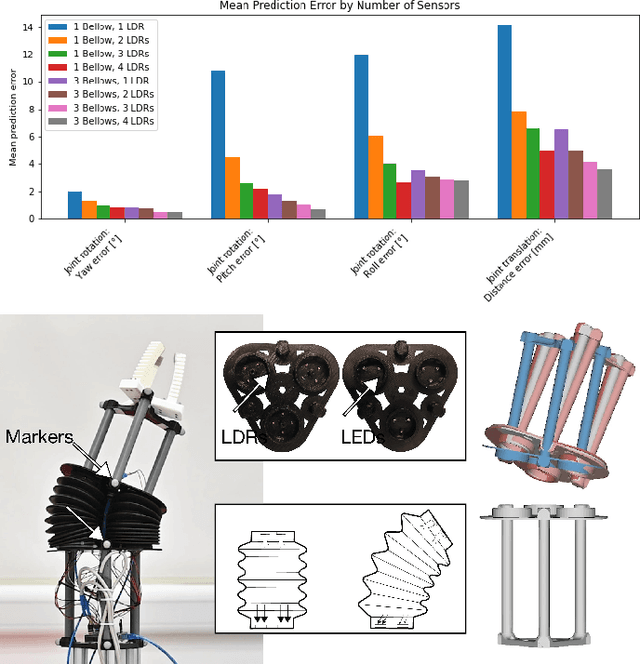

Sensing and Reconstruction of 3D Deformation on Pneumatic Soft Robots

Dec 22, 2020

Abstract:Real-time proprioception is a challenging problem for soft robots, which have almost infinite degrees-of-freedom in body deformation. When multiple actuators are used, it becomes more difficult as deformation can also occur on actuators caused by interaction between each other. To tackle this problem, we present a method in this paper to sense and reconstruct 3D deformation on pneumatic soft robots by first integrating multiple low-cost sensors inside the chambers of pneumatic actuators and then using machine learning to convert the captured signals into shape parameters of soft robots. An exterior motion capture system is employed to generate the datasets for both training and testing. With the help of good shape parameterization, the 3D shape of a soft robot can be accurately reconstructed from signals obtained from multiple sensors. We demonstrate the effectiveness of this approach on two designs of soft robots -- a robotic joint and a deformable membrane. After parameterizing the deformation of these soft robots into compact shape parameters, we can effectively train the neural networks to reconstruct the 3D deformation from the sensor signals. The sensing and shape prediction pipeline can run at 50Hz in real-time on a consumer-level device.

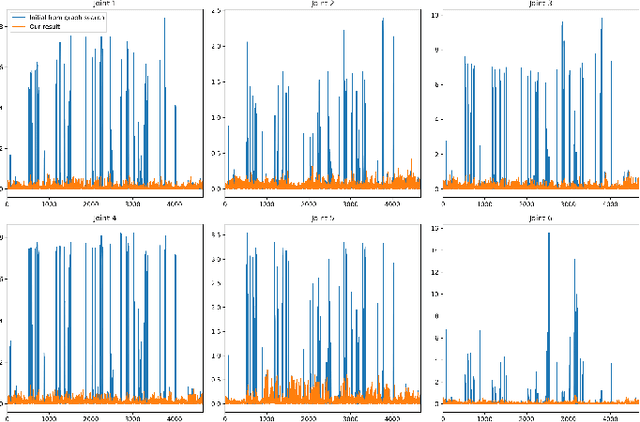

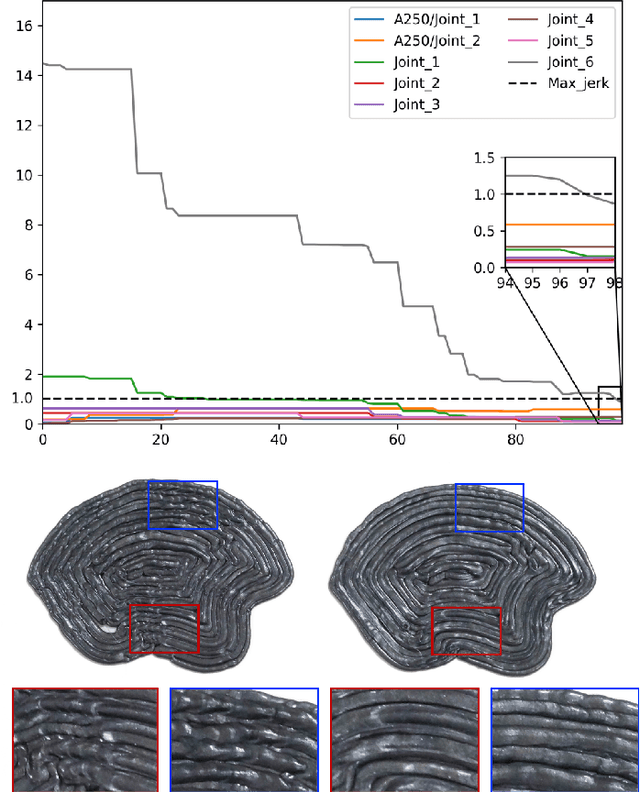

Planning Jerk-Optimized Trajectory with Discrete-Time Constraints for Redundant Robots

Sep 14, 2019

Abstract:We present a method for effectively planning the motion trajectory of robots in manufacturing tasks, the tool-paths of which are usually complex and have a large number of discrete-time constraints as waypoints. Kinematic redundancy also exists in these robotic systems. The jerk of motion is optimized in our trajectory planning method at the meanwhile of fabrication process to improve the quality of fabrication.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge