Ya Xiong

Vision-Based Early Fault Diagnosis and Self-Recovery for Strawberry Harvesting Robots

Jan 05, 2026Abstract:Strawberry harvesting robots faced persistent challenges such as low integration of visual perception, fruit-gripper misalignment, empty grasping, and strawberry slippage from the gripper due to insufficient gripping force, all of which compromised harvesting stability and efficiency in orchard environments. To overcome these issues, this paper proposed a visual fault diagnosis and self-recovery framework that integrated multi-task perception with corrective control strategies. At the core of this framework was SRR-Net, an end-to-end multi-task perception model that simultaneously performed strawberry detection, segmentation, and ripeness estimation, thereby unifying visual perception with fault diagnosis. Based on this integrated perception, a relative error compensation method based on the simultaneous target-gripper detection was designed to address positional misalignment, correcting deviations when error exceeded the tolerance threshold. To mitigate empty grasping and fruit-slippage faults, an early abort strategy was implemented. A micro-optical camera embedded in the end-effector provided real-time visual feedback, enabling grasp detection during the deflating stage and strawberry slip prediction during snap-off through MobileNet V3-Small classifier and a time-series LSTM classifier. Experiments demonstrated that SRR-Net maintained high perception accuracy. For detection, it achieved a precision of 0.895 and recall of 0.813 on strawberries, and 0.972/0.958 on hands. In segmentation, it yielded a precision of 0.887 and recall of 0.747 for strawberries, and 0.974/0.947 for hands. For ripeness estimation, SRR-Net attained a mean absolute error of 0.035, while simultaneously supporting multi-task perception and sustaining a competitive inference speed of 163.35 FPS.

A Fast Path-Planning Method for Continuous Harvesting of Table-Top Grown Strawberries

Jan 09, 2025

Abstract:Continuous harvesting and storage of multiple fruits in a single operation allow robots to significantly reduce the travel distance required for repetitive back-and-forth movements. Traditional collision-free path planning algorithms, such as Rapidly-Exploring Random Tree (RRT) and A-star (A), often fail to meet the demands of efficient continuous fruit harvesting due to their low search efficiency and the generation of excessive redundant points. This paper presents the Interactive Local Minima Search Algorithm (ILMSA), a fast path-planning method designed for the continuous harvesting of table-top grown strawberries. The algorithm featured an interactive node expansion strategy that iteratively extended and refined collision-free path segments based on local minima points. To enable the algorithm to function in 3D, the 3D environment was projected onto multiple 2D planes, generating optimal paths on each plane. The best path was then selected, followed by integrating and smoothing the 3D path segments. Simulations demonstrated that ILMSA outperformed existing methods, reducing path length by 21.5% and planning time by 97.1% compared to 3D-RRT, while achieving 11.6% shorter paths and 25.4% fewer nodes than the Lowest Point of the Strawberry (LPS) algorithm in 3D environments. In 2D, ILMSA achieved path lengths 16.2% shorter than A, 23.4% shorter than RRT, and 20.9% shorter than RRT-Connect, while being over 96% faster and generating significantly fewer nodes. Field tests confirmed ILMSA's suitability for complex agricultural tasks, having a combined planning and execution time and an average path length that were approximately 58% and 69%, respectively, of those achieved by the LPS algorithm.

Design and Control of a Novel Six-Degree-of-Freedom Hybrid Robotic Arm

Jul 29, 2024

Abstract:Robotic arms are key components in fruit-harvesting robots. In agricultural settings, conventional serial or parallel robotic arms often fall short in meeting the demands for a large workspace, rapid movement, enhanced capability of obstacle avoidance and affordability. This study proposes a novel hybrid six-degree-of-freedom (DoF) robotic arm that combines the advantages of parallel and serial mechanisms. Inspired by yoga, we designed two sliders capable of moving independently along a single rail, acting as two feet. These sliders are interconnected with linkages and a meshed-gear set, allowing the parallel mechanism to lower itself and perform a split to pass under obstacles. This unique feature allows the arm to avoid obstacles such as pipes, tables and beams typically found in greenhouses. Integrated with serially mounted joints, the patented hybrid arm is able to maintain the end's pose even when it moves with a mobile platform, facilitating fruit picking with the optimal pose in dynamic conditions. Moreover, the hybrid arm's workspace is substantially larger, being almost three times the volume of UR3 serial arms and fourteen times that of the ABB IRB parallel arms. Experiments show that the repeatability errors are 0.017 mm, 0.03 mm and 0.109 mm for the two sliders and the arm's end, respectively, providing sufficient precision for agricultural robots.

Multi-Arm Robot Task Planning for Fruit Harvesting Using Multi-Agent Reinforcement Learning

Mar 01, 2023Abstract:The emergence of harvesting robotics offers a promising solution to the issue of limited agricultural labor resources and the increasing demand for fruits. Despite notable advancements in the field of harvesting robotics, the utilization of such technology in orchards is still limited. The key challenge is to improve operational efficiency. Taking into account inner-arm conflicts, couplings of DoFs, and dynamic tasks, we propose a task planning strategy for a harvesting robot with four arms in this paper. The proposed method employs a Markov game framework to formulate the four-arm robotic harvesting task, which avoids the computational complexity of solving an NP-hard scheduling problem. Furthermore, a multi-agent reinforcement learning (MARL) structure with a fully centralized collaboration protocol is used to train a MARL-based task planning network. Several simulations and orchard experiments are conducted to validate the effectiveness of the proposed method for a multi-arm harvesting robot in comparison with the existing method.

Push and Drag: An Active Obstacle Separation Method for Fruit Harvesting Robots

Apr 20, 2020

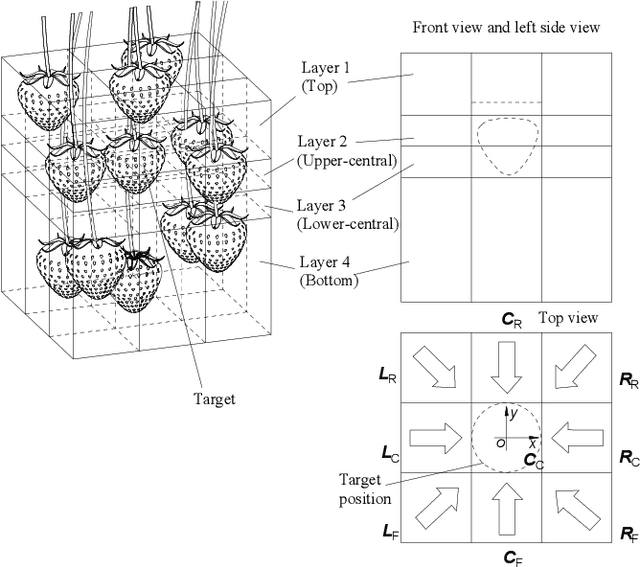

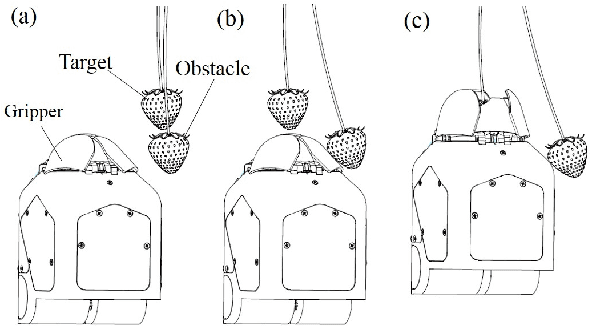

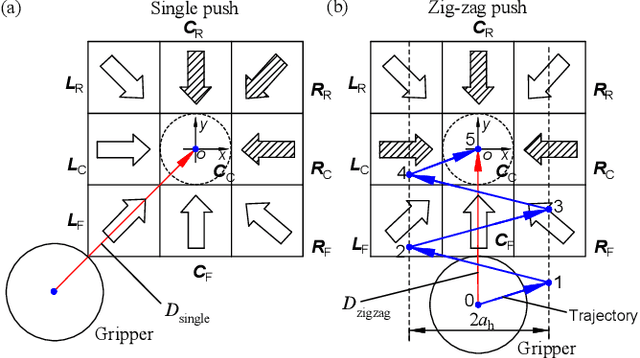

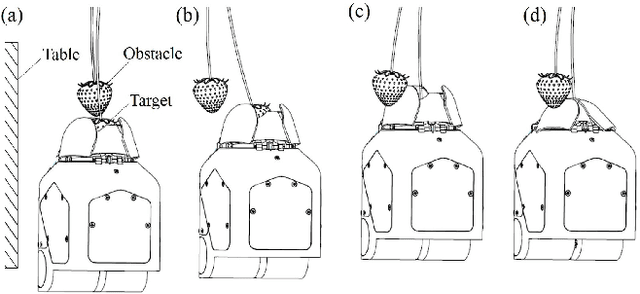

Abstract:Selectively picking a target fruit surrounded by obstacles is one of the major challenges for fruit harvesting robots. Different from traditional obstacle avoidance methods, this paper presents an active obstacle separation strategy that combines push and drag motions. The separation motion and trajectory are generated based on the 3D visual perception of the obstacle information around the target. A linear push is used to clear the obstacles from the area below the target, while a zig-zag push that contains several linear motions is proposed to push aside more dense obstacles. The zig-zag push can generate multi-directional pushes and the side-to-side motion can break the static contact force between the target and obstacles, thus helping the gripper to receive a target in more complex situations. Moreover, we propose a novel drag operation to address the issue of mis-capturing obstacles located above the target, in which the gripper drags the target to a place with fewer obstacles and then pushes back to move the obstacles aside for further detachment. Furthermore, an image processing pipeline consisting of color thresholding, object detection using deep learning and point cloud operation, is developed to implement the proposed method on a harvesting robot. Field tests show that the proposed method can improve the picking performance substantially. This method helps to enable complex clusters of fruits to be harvested with a higher success rate than conventional methods.

Design and Evaluation of a Novel Cable-Driven Gripper with Perception Capabilities for Strawberry Picking Robots

Apr 25, 2018

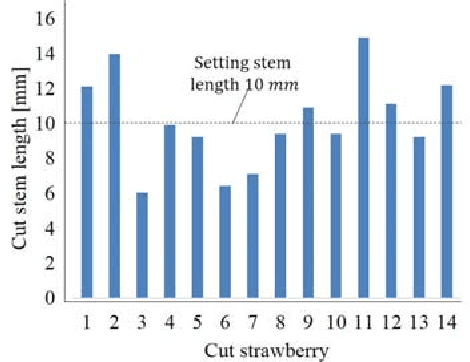

Abstract:This paper presents a novel cable-driven gripper with perception capabilities for autonomous harvesting of strawberries. Experiments show that the gripper allows for more accurate and faster picking of strawberries compared to existing systems. The gripper consists of four functional parts for sensing, picking, transmission, and storing. It has six fingers that open to form a closed space to swallow a target strawberry and push other surrounding berries away from the target. Equipped with three IR sensors, the gripper controls a manipulator arm to correct for positional error, and can thus pick strawberries that are not exactly localized by the vision algorithm, improving the robustness. Experiments show that the gripper is gentle on the berries as it merely cuts the stem and there is no physical interaction with the berries during the cutting process. We show that the gripper has close-to-perfect successful picking rate when addressing isolated strawberries. By including internal perception, we get high positional error tolerance, and avoid using slow, high-level closed-loop control. Moreover, the gripper can store several berries, which reduces the overall travel distance for the manipulator, and decreases the time needed to pick a single strawberry substantially. The experiments show that the gripper design decreased picking execution time noticeably compared to results found in literature.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge