Vispi Karkaria

Adaptive Digital Twin of Sheet Metal Forming via Proper Orthogonal Decomposition-Based Koopman Operator with Model Predictive Control

Nov 13, 2025

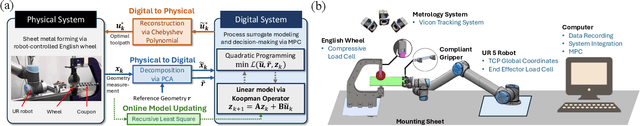

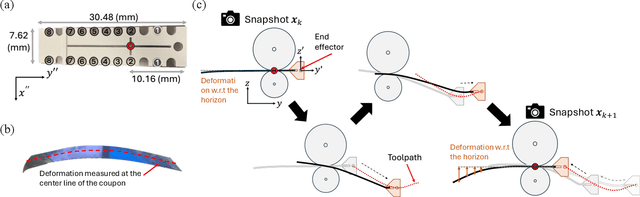

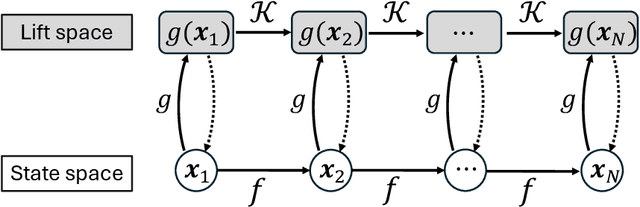

Abstract:Digital Twin (DT) technologies are transforming manufacturing by enabling real-time prediction, monitoring, and control of complex processes. Yet, applying DT to deformation-based metal forming remains challenging because of the strongly coupled spatial-temporal behavior and the nonlinear relationship between toolpath and material response. For instance, sheet-metal forming by the English wheel, a highly flexible but artisan-dependent process, still lacks digital counterparts that can autonomously plan and adapt forming strategies. This study presents an adaptive DT framework that integrates Proper Orthogonal Decomposition (POD) for physics-aware dimensionality reduction with a Koopman operator for representing nonlinear system in a linear lifted space for the real-time decision-making via model predictive control (MPC). To accommodate evolving process conditions or material states, an online Recursive Least Squares (RLS) algorithm is introduced to update the operator coefficients in real time, enabling continuous adaptation of the DT model as new deformation data become available. The proposed framework is experimentally demonstrated on a robotic English Wheel sheet metal forming system, where deformation fields are measured and modeled under varying toolpaths. Results show that the adaptive DT is capable of controlling the forming process to achieve the given target shape by effectively capturing non-stationary process behaviors. Beyond this case study, the proposed framework establishes a generalizable approach for interpretable, adaptive, and computationally-efficient DT of nonlinear manufacturing systems, bridging reduced-order physics representations with data-driven adaptability to support autonomous process control and optimization.

An Attention-based Spatio-Temporal Neural Operator for Evolving Physics

Jun 12, 2025Abstract:In scientific machine learning (SciML), a key challenge is learning unknown, evolving physical processes and making predictions across spatio-temporal scales. For example, in real-world manufacturing problems like additive manufacturing, users adjust known machine settings while unknown environmental parameters simultaneously fluctuate. To make reliable predictions, it is desired for a model to not only capture long-range spatio-temporal interactions from data but also adapt to new and unknown environments; traditional machine learning models excel at the first task but often lack physical interpretability and struggle to generalize under varying environmental conditions. To tackle these challenges, we propose the Attention-based Spatio-Temporal Neural Operator (ASNO), a novel architecture that combines separable attention mechanisms for spatial and temporal interactions and adapts to unseen physical parameters. Inspired by the backward differentiation formula (BDF), ASNO learns a transformer for temporal prediction and extrapolation and an attention-based neural operator for handling varying external loads, enhancing interpretability by isolating historical state contributions and external forces, enabling the discovery of underlying physical laws and generalizability to unseen physical environments. Empirical results on SciML benchmarks demonstrate that ASNO outperforms over existing models, establishing its potential for engineering applications, physics discovery, and interpretable machine learning.

Real-Time Decision-Making for Digital Twin in Additive Manufacturing with Model Predictive Control using Time-Series Deep Neural Networks

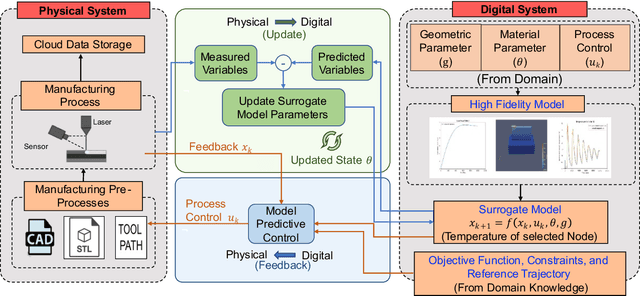

Jan 10, 2025Abstract:Digital Twin-a virtual replica of a physical system enabling real-time monitoring, model updating, prediction, and decision-making-combined with recent advances in machine learning (ML), offers new opportunities for proactive control strategies in autonomous manufacturing. However, achieving real-time decision-making with Digital Twins requires efficient optimization driven by accurate predictions of highly nonlinear manufacturing systems. This paper presents a simultaneous multi-step Model Predictive Control (MPC) framework for real-time decision-making, using a multi-variate deep neural network (DNN), named Time-Series Dense Encoder (TiDE), as the surrogate model. Different from the models in conventional MPC which only provide one-step ahead prediction, TiDE is capable of predicting future states within the prediction horizon in one shot (multi-step), significantly accelerating MPC. Using Directed Energy Deposition additive manufacturing as a case study, we demonstrate the effectiveness of the proposed MPC in achieving melt pool temperature tracking to ensure part quality, while reducing porosity defects by regulating laser power to maintain melt pool depth constraints. In this work, we first show that TiDE is capable of accurately predicting melt pool temperature and depth. Second, we demonstrate that the proposed MPC achieves precise temperature tracking while satisfying melt pool depth constraints within a targeted dilution range (10%-30%), reducing potential porosity defects. Compared to the PID controller, MPC results in smoother and less fluctuating laser power profiles with competitive or superior melt pool temperature control performance. This demonstrates MPC's proactive control capabilities, leveraging time-series prediction and real-time optimization, positioning it as a powerful tool for future Digital Twin applications and real-time process optimization in manufacturing.

A Digital Twin Framework Utilizing Machine Learning for Robust Predictive Maintenance: Enhancing Tire Health Monitoring

Aug 12, 2024

Abstract:We introduce a novel digital twin framework for predictive maintenance of long-term physical systems. Using monitoring tire health as an application, we show how the digital twin framework can be used to enhance automotive safety and efficiency, and how the technical challenges can be overcome using a three-step approach. Firstly, for managing the data complexity over a long operation span, we employ data reduction techniques to concisely represent physical tires using historical performance and usage data. Relying on these data, for fast real-time prediction, we train a transformer-based model offline on our concise dataset to predict future tire health over time, represented as Remaining Casing Potential (RCP). Based on our architecture, our model quantifies both epistemic and aleatoric uncertainty, providing reliable confidence intervals around predicted RCP. Secondly, to incorporate real-time data, we update the predictive model in the digital twin framework, ensuring its accuracy throughout its life span with the aid of hybrid modeling and the use of discrepancy function. Thirdly, to assist decision making in predictive maintenance, we implement a Tire State Decision Algorithm, which strategically determines the optimal timing for tire replacement based on RCP forecasted by our transformer model. This approach ensures our digital twin accurately predicts system health, continually refines its digital representation, and supports predictive maintenance decisions. Our framework effectively embodies a physical system, leveraging big data and machine learning for predictive maintenance, model updates, and decision-making.

Towards a Digital Twin Framework in Additive Manufacturing: Machine Learning and Bayesian Optimization for Time Series Process Optimization

Feb 27, 2024

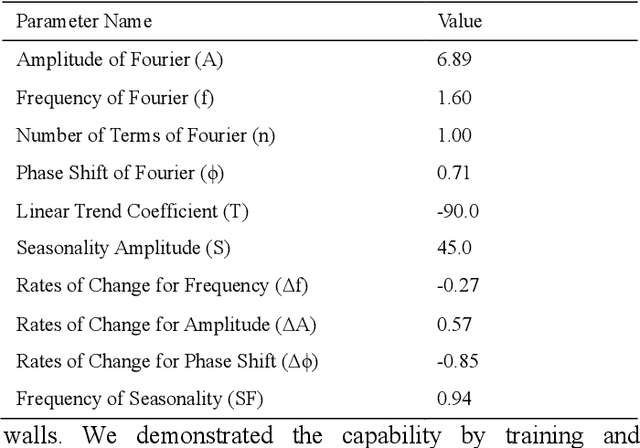

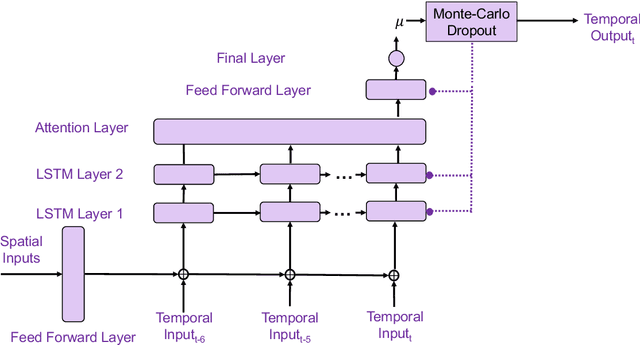

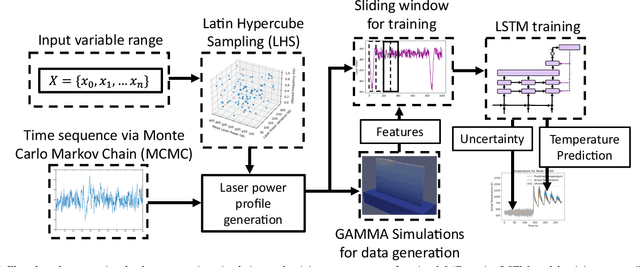

Abstract:Laser-directed-energy deposition (DED) offers advantages in additive manufacturing (AM) for creating intricate geometries and material grading. Yet, challenges like material inconsistency and part variability remain, mainly due to its layer-wise fabrication. A key issue is heat accumulation during DED, which affects the material microstructure and properties. While closed-loop control methods for heat management are common in DED research, few integrate real-time monitoring, physics-based modeling, and control in a unified framework. Our work presents a digital twin (DT) framework for real-time predictive control of DED process parameters to meet specific design objectives. We develop a surrogate model using Long Short-Term Memory (LSTM)-based machine learning with Bayesian Inference to predict temperatures in DED parts. This model predicts future temperature states in real time. We also introduce Bayesian Optimization (BO) for Time Series Process Optimization (BOTSPO), based on traditional BO but featuring a unique time series process profile generator with reduced dimensions. BOTSPO dynamically optimizes processes, identifying optimal laser power profiles to attain desired mechanical properties. The established process trajectory guides online optimizations, aiming to enhance performance. This paper outlines the digital twin framework's components, promoting its integration into a comprehensive system for AM.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge