Rujing Zha

Machine Learning-Driven Creep Law Discovery Across Alloy Compositional Space

Jan 13, 2026Abstract:Hihg-temperature creep characterization of structural alloys traditionally relies on serial uniaxial tests, which are highly inefficient for exploring the large search space of alloy compositions and for material discovery. Here, we introduce a machine-learning-assisted, high-throughput framework for creep law identification based on a dimple array bulge instrument (DABI) configuration, which enables parallel creep testing of 25 dimples, each fabricated from a different alloy, in a single experiment. Full-field surface displacements of dimples undergoing time-dependent creep-induced bulging under inert gas pressure are measured by 3D digital image correlation. We train a recurrent neural network (RNN) as a surrogate model, mapping creep parameters and loading conditions to the time-dependent deformation response of DABI. Coupling this surrogate with a particle swarm optimization scheme enables rapid and global inverse identification with sparsity regularization of creep parameters from experiment displacement-time histories. In addition, we propose a phenomenological creep law with a time-dependent stress exponent that captures the sigmoidal primary creep observed in wrought INCONEL 625 and extracts its temperature dependence from DABI test at multiple temperatures. Furthermore, we employ a general creep law combining several conventional forms together with regularized inversion to identify the creep laws for 47 additional Fe-, Ni-, and Co-rich alloys and to automatically select the dominant functional form for each alloy. This workflow combined with DABI experiment provides a quantitative, high-throughput creep characterization platform that is compatible with data mining, composition-property modeling, and nonlinear structural optimization with creep behavior across a large alloy design space.

Towards a Digital Twin Framework in Additive Manufacturing: Machine Learning and Bayesian Optimization for Time Series Process Optimization

Feb 27, 2024

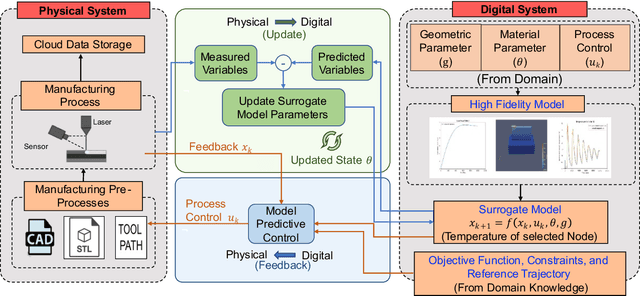

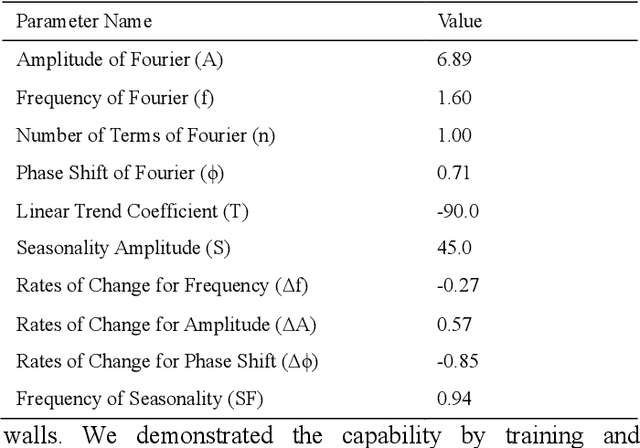

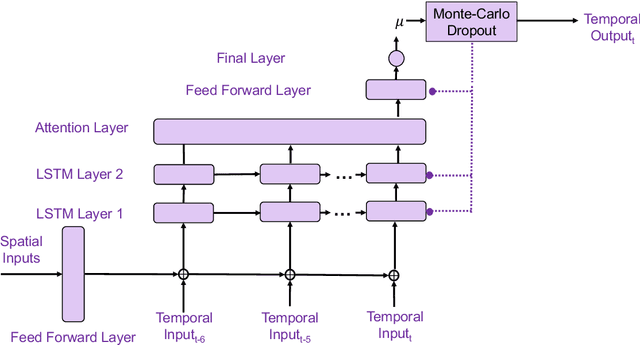

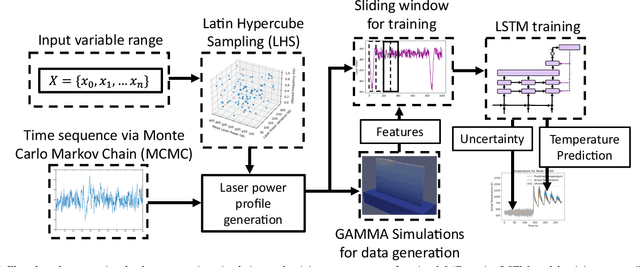

Abstract:Laser-directed-energy deposition (DED) offers advantages in additive manufacturing (AM) for creating intricate geometries and material grading. Yet, challenges like material inconsistency and part variability remain, mainly due to its layer-wise fabrication. A key issue is heat accumulation during DED, which affects the material microstructure and properties. While closed-loop control methods for heat management are common in DED research, few integrate real-time monitoring, physics-based modeling, and control in a unified framework. Our work presents a digital twin (DT) framework for real-time predictive control of DED process parameters to meet specific design objectives. We develop a surrogate model using Long Short-Term Memory (LSTM)-based machine learning with Bayesian Inference to predict temperatures in DED parts. This model predicts future temperature states in real time. We also introduce Bayesian Optimization (BO) for Time Series Process Optimization (BOTSPO), based on traditional BO but featuring a unique time series process profile generator with reduced dimensions. BOTSPO dynamically optimizes processes, identifying optimal laser power profiles to attain desired mechanical properties. The established process trajectory guides online optimizations, aiming to enhance performance. This paper outlines the digital twin framework's components, promoting its integration into a comprehensive system for AM.

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge