Urtzi Otamendi

REMoH: A Reflective Evolution of Multi-objective Heuristics approach via Large Language Models

Jun 09, 2025

Abstract:Multi-objective optimization is fundamental in complex decision-making tasks. Traditional algorithms, while effective, often demand extensive problem-specific modeling and struggle to adapt to nonlinear structures. Recent advances in Large Language Models (LLMs) offer enhanced explainability, adaptability, and reasoning. This work proposes Reflective Evolution of Multi-objective Heuristics (REMoH), a novel framework integrating NSGA-II with LLM-based heuristic generation. A key innovation is a reflection mechanism that uses clustering and search-space reflection to guide the creation of diverse, high-quality heuristics, improving convergence and maintaining solution diversity. The approach is evaluated on the Flexible Job Shop Scheduling Problem (FJSSP) in-depth benchmarking against state-of-the-art methods using three instance datasets: Dauzere, Barnes, and Brandimarte. Results demonstrate that REMoH achieves competitive results compared to state-of-the-art approaches with reduced modeling effort and enhanced adaptability. These findings underscore the potential of LLMs to augment traditional optimization, offering greater flexibility, interpretability, and robustness in multi-objective scenarios.

Exploring Multi-Agent Reinforcement Learning for Unrelated Parallel Machine Scheduling

Nov 12, 2024

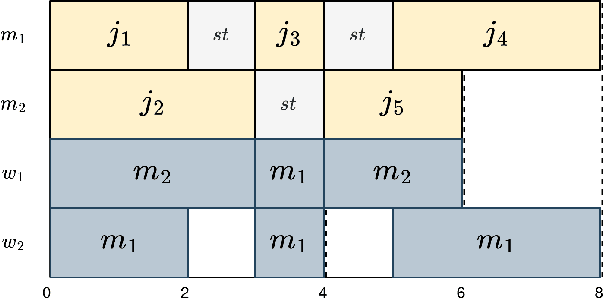

Abstract:Scheduling problems pose significant challenges in resource, industry, and operational management. This paper addresses the Unrelated Parallel Machine Scheduling Problem (UPMS) with setup times and resources using a Multi-Agent Reinforcement Learning (MARL) approach. The study introduces the Reinforcement Learning environment and conducts empirical analyses, comparing MARL with Single-Agent algorithms. The experiments employ various deep neural network policies for single- and Multi-Agent approaches. Results demonstrate the efficacy of the Maskable extension of the Proximal Policy Optimization (PPO) algorithm in Single-Agent scenarios and the Multi-Agent PPO algorithm in Multi-Agent setups. While Single-Agent algorithms perform adequately in reduced scenarios, Multi-Agent approaches reveal challenges in cooperative learning but a scalable capacity. This research contributes insights into applying MARL techniques to scheduling optimization, emphasizing the need for algorithmic sophistication balanced with scalability for intelligent scheduling solutions.

Integrated Water Resource Management in the Segura Hydrographic Basin: An Artificial Intelligence Approach

Nov 11, 2024

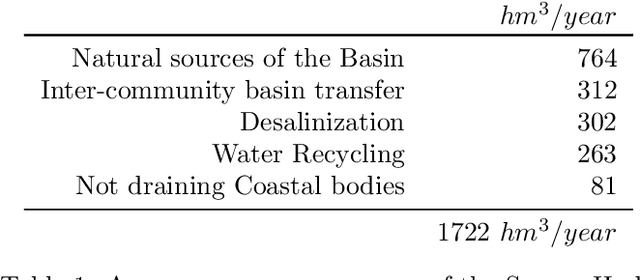

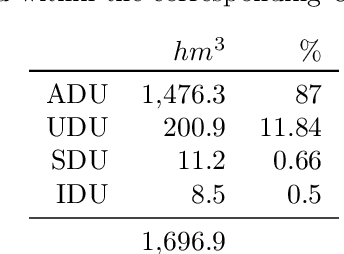

Abstract:Managing resources effectively in uncertain demand, variable availability, and complex governance policies is a significant challenge. This paper presents a paradigmatic framework for addressing these issues in water management scenarios by integrating advanced physical modelling, remote sensing techniques, and Artificial Intelligence algorithms. The proposed approach accurately predicts water availability, estimates demand, and optimizes resource allocation on both short- and long-term basis, combining a comprehensive hydrological model, agronomic crop models for precise demand estimation, and Mixed-Integer Linear Programming for efficient resource distribution. In the study case of the Segura Hydrographic Basin, the approach successfully allocated approximately 642 million cubic meters ($hm^3$) of water over six months, minimizing the deficit to 9.7% of the total estimated demand. The methodology demonstrated significant environmental benefits, reducing CO2 emissions while optimizing resource distribution. This robust solution supports informed decision-making processes, ensuring sustainable water management across diverse contexts. The generalizability of this approach allows its adaptation to other basins, contributing to improved governance and policy implementation on a broader scale. Ultimately, the methodology has been validated and integrated into the operational water management practices in the Segura Hydrographic Basin in Spain.

* 15 pages, 14 figures, 8 tables

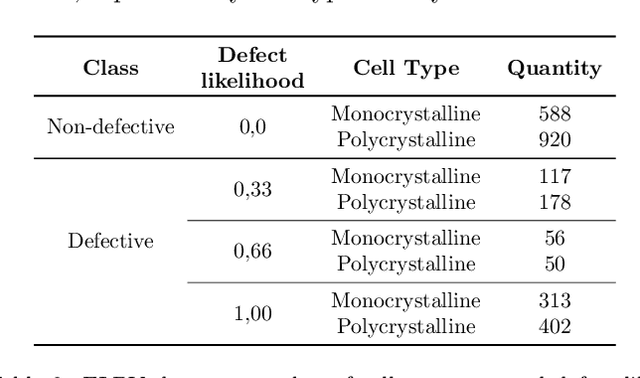

A scalable framework for annotating photovoltaic cell defects in electroluminescence images

Dec 15, 2022

Abstract:The correct functioning of photovoltaic (PV) cells is critical to ensuring the optimal performance of a solar plant. Anomaly detection techniques for PV cells can result in significant cost savings in operation and maintenance (O&M). Recent research has focused on deep learning techniques for automatically detecting anomalies in Electroluminescence (EL) images. Automated anomaly annotations can improve current O&M methodologies and help develop decision-making systems to extend the life-cycle of the PV cells and predict failures. This paper addresses the lack of anomaly segmentation annotations in the literature by proposing a combination of state-of-the-art data-driven techniques to create a Golden Standard benchmark. The proposed method stands out for (1) its adaptability to new PV cell types, (2) cost-efficient fine-tuning, and (3) leverage public datasets to generate advanced annotations. The methodology has been validated in the annotation of a widely used dataset, obtaining a reduction of the annotation cost by 60%.

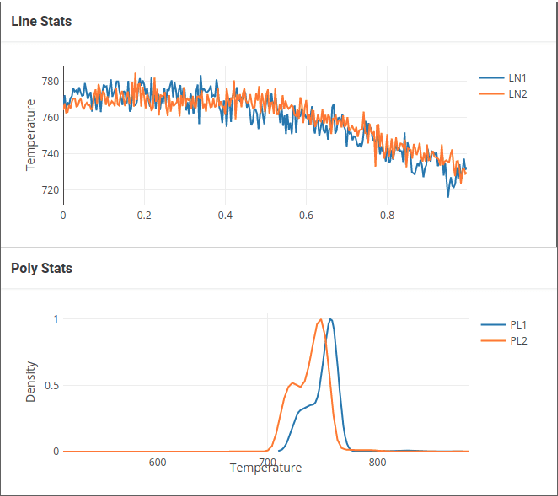

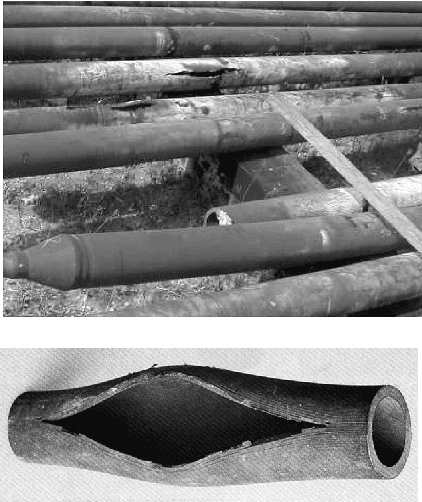

A novel method for error analysis in radiation thermometry with application to industrial furnaces

Jan 10, 2022

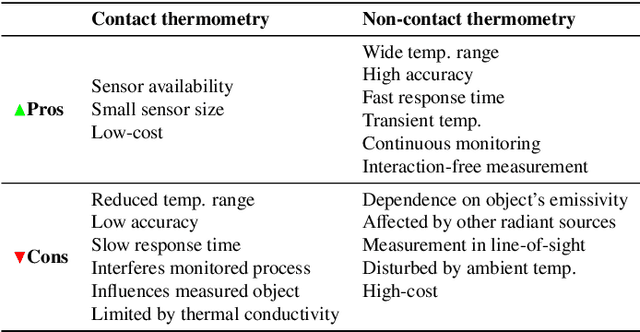

Abstract:Accurate temperature measurements are essential for the proper monitoring and control of industrial furnaces. However, measurement uncertainty is a risk for such a critical parameter. Certain instrumental and environmental errors must be considered when using spectral-band radiation thermometry techniques, such as the uncertainty in the emissivity of the target surface, reflected radiation from surrounding objects, or atmospheric absorption and emission, to name a few. Undesired contributions to measured radiation can be isolated using measurement models, also known as error-correction models. This paper presents a methodology for budgeting significant sources of error and uncertainty during temperature measurements in a petrochemical furnace scenario. A continuous monitoring system is also presented, aided by a deep-learning-based measurement correction model, to allow domain experts to analyze the furnace's operation in real-time. To validate the proposed system's functionality, a real-world application case in a petrochemical plant is presented. The proposed solution demonstrates the viability of precise industrial furnace monitoring, thereby increasing operational security and improving the efficiency of such energy-intensive systems.

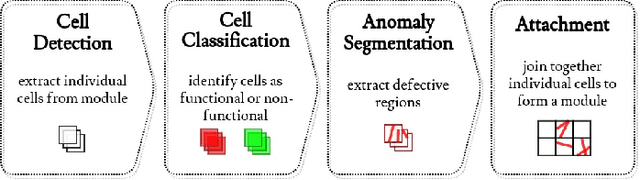

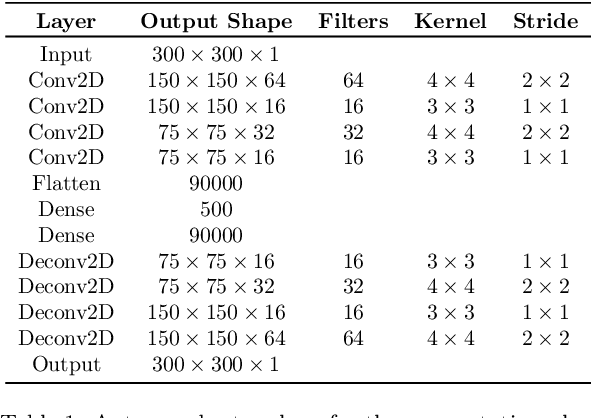

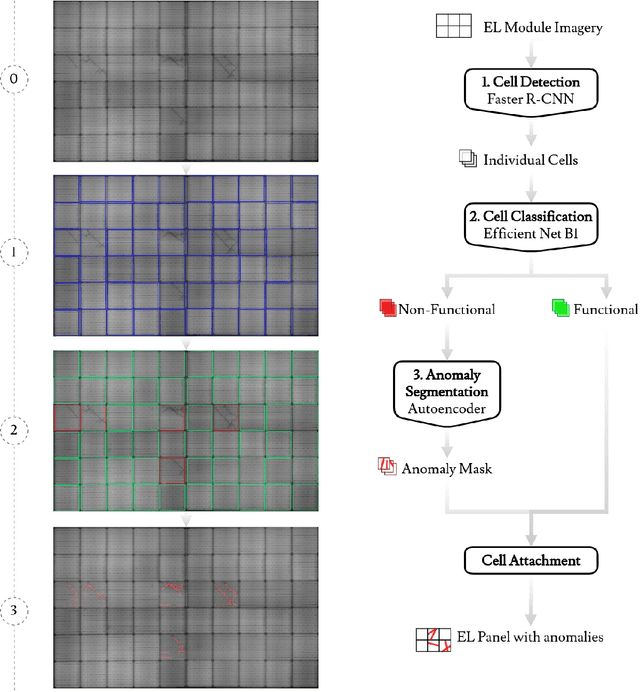

Segmentation of cell-level anomalies in electroluminescence images of photovoltaic modules

Jun 21, 2021

Abstract:In the operation & maintenance (O&M) of photovoltaic (PV) plants, the early identification of failures has become crucial to maintain productivity and prolong components' life. Of all defects, cell-level anomalies can lead to serious failures and may affect surrounding PV modules in the long run. These fine defects are usually captured with high spatial resolution electroluminescence (EL) imaging. The difficulty of acquiring such images has limited the availability of data. For this work, multiple data resources and augmentation techniques have been used to surpass this limitation. Current state-of-the-art detection methods extract barely low-level information from individual PV cell images, and their performance is conditioned by the available training data. In this article, we propose an end-to-end deep learning pipeline that detects, locates and segments cell-level anomalies from entire photovoltaic modules via EL images. The proposed modular pipeline combines three deep learning techniques: 1. object detection (modified Faster-RNN), 2. image classification (EfficientNet) and 3. weakly supervised segmentation (autoencoder). The modular nature of the pipeline allows to upgrade the deep learning models to the further improvements in the state-of-the-art and also extend the pipeline towards new functionalities.

* 16 pages, 14 figures

Add to Chrome

Add to Chrome Add to Firefox

Add to Firefox Add to Edge

Add to Edge